Method for preparing telechelic polycarboxylic acid water reducer

A technology of telechelic polycarboxylic acid and water reducing agent is applied in the application field of concrete admixture, which can solve the problems of large application limitation and single functional group, and achieves enhancement of early strength and toughness, simple process, and increased molecular weight. The effect of polarity and steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

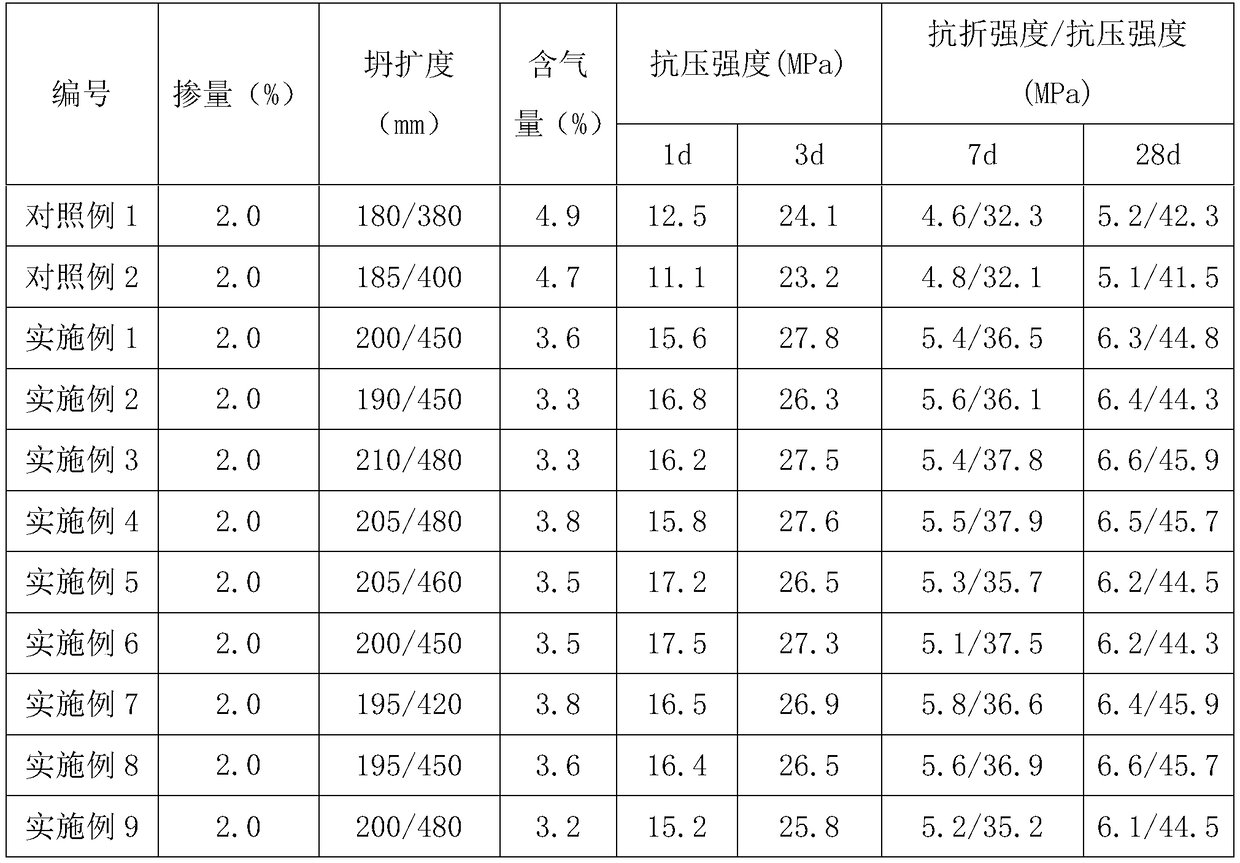

Examples

example 1

[0024] (1) Preparation of nitrogen and oxygen stable free radicals: 1 mol of pentaerythritol and 10 mol of N-methyl-4-hydroxypiperidine were reacted at 35°C for 4 hours under the action of 0.015 mol of sodium hydroxide to obtain the initiator nitrogen and oxygen stable free radicals. base.

[0025] (2) Preparation of unsaturated polyether macromonomer: After adding 0.01mol melamine-amide and 0.003mol sodium methoxide to the reaction kettle, vacuumize, replace with nitrogen, heat to 130°C, and then continuously add 1mol epoxy Ethane undergoes ring-opening polymerization reaction to prepare unsaturated polyether macromonomer with number average molecular weight of 800.

[0026] (3) Preparation of telechelic polycarboxylate water-reducer: 1 mol step (2) unsaturated polyether macromonomer, 2.5 mol cyanovinylaniline and 0.15 mol 2,4-diphenyl-4-methyl Under the action of 0.06 mol of nitroxide stabilized free radicals in step (1), NMRP reaction occurs at 65° C., and the reaction tim...

example 2

[0028] (1) Preparation of nitrogen and oxygen stable free radicals: Under the action of 1mol tripentaerythritol and 12mol 2,2,6,6-tetramethylpiperidine and 0.005mol potassium hydroxide, carry out a catalytic reaction at 40°C for 3h to obtain the initiator nitrogen Oxygen stabilizes free radicals.

[0029] (2) Preparation of unsaturated polyether macromonomer: After adding 0.02mol triallyl cyanurate and 0.004mol sodium hydride into the reaction kettle, vacuumize, replace with nitrogen, heat to 140°C, and then Continuously add 1 mol of propylene oxide to carry out ring-opening polymerization reaction to prepare an unsaturated polyether macromonomer with a number average molecular weight of 1400.

[0030] (3) Preparation of telechelic polycarboxylate water reducer: 1mol step (2) unsaturated polyether macromonomer, 3mol styryl triphenylamine and 0.05mol dodecyl mercaptan in 0.23mol step (1 ) NMRP reaction occurs at 70°C under the action of nitrogen and oxygen stable free radicals...

example 3

[0032] (1) Preparation of nitrogen-oxygen stable free radicals: 1 mol of neopentyl glycol and 14 mol of 2,2,6,6-tetramethylpiperidine were reacted at 45°C for 5 hours under the action of 0.01 mol of potassium hydride to obtain Nitrogen stabilizes free radicals.

[0033] (2) Preparation of unsaturated polyether macromonomer: After adding 0.004mol trimethylcyanurate and 0.005mol potassium hydride into the reaction kettle, vacuumize, replace with nitrogen, heat to 150°C, and then continuously Add 1 mol of butylene oxide to carry out ring-opening polymerization reaction to prepare an unsaturated polyether macromonomer with a number average molecular weight of 1400.

[0034] (3) Preparation of telechelic polycarboxylate water-reducer: 1 mol step (2) unsaturated polyether macromonomer, 3.5 mol N,N-diphenyl-4-vinylaniline and 0.08 mol 2-mercapto Under the action of 0.08 mol of ethanesulfonic acid stable free radicals in step (1), NMRP reaction occurs at 75° C., and the reaction time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com