Synthetic method of N,N'-4,4'-diphenylmethyene bismaleimide

A technology of bismaleimide and diphenylmethane, which is applied in the field of synthesis of diphenylmethane bismaleimide, can solve the problems of high cost, single reaction system, difficult wastewater treatment, etc., and achieve fast heating speed, The effect of good selectivity and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

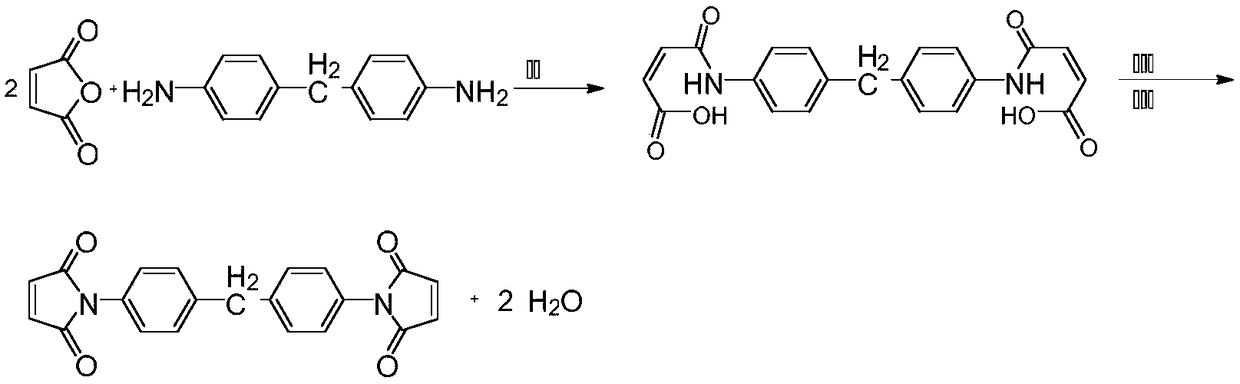

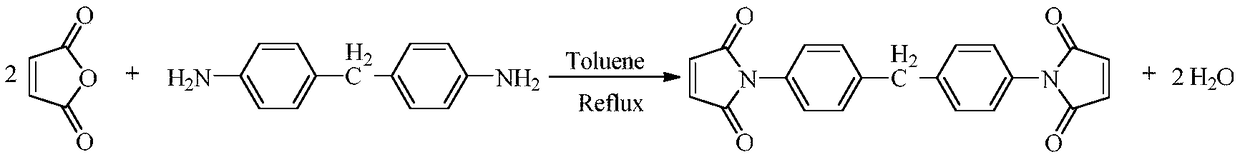

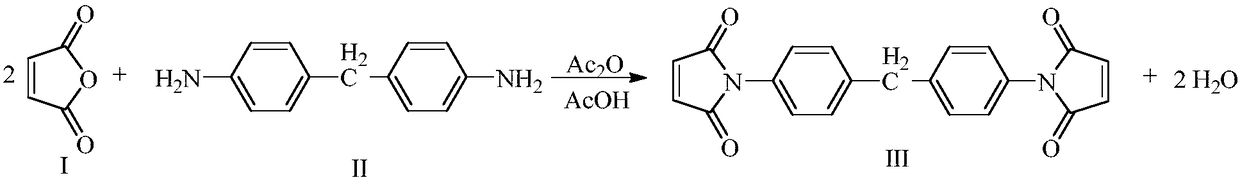

Method used

Image

Examples

Embodiment 1

[0024] A kind of synthetic method of embodiment 1 diphenylmethane bismaleimide, concrete implementation is as follows:

[0025] Maleic anhydride (9.8g, 100mmol, 99.0%), 4,4'-diaminodiphenylmethane (8.9g, 45mmol), acetic anhydride (10.7g, 105mmol), glacial acetic acid (50g, 99%) were placed In a 100mL microwave reaction tube, put it into a microwave reactor after being dissolved, set the reaction temperature to 80°C, and the reaction time to 30 minutes, turn on the microwave reactor, and stir.

[0026] After the reaction is over, transfer the reaction solution to a distillation device, distill at normal pressure, collect distillate acetic acid, add 80 g of methanol after evaporation to dryness, transfer to a reflux condensation device, reflux for 10 minutes, cool, cool to about 5°C, and suction filter, the obtained solid is 80 After vacuum drying at ℃ for 2 hours, 14.6g of a light yellow solid was obtained, i.e. the target compound diphenylmethane bismaleimide, with a purity of...

Embodiment 2

[0027] A kind of synthetic method of embodiment 2 diphenylmethane bismaleimide, concrete implementation is as follows:

[0028] Maleic anhydride (9.8g, 100mmol, 99.0%), 4,4'-diaminodiphenylmethane (9.9g, 50mmol), acetic anhydride (12.3g, 120mmol), glacial acetic acid (60g, 99%) were placed In a 100mL microwave reaction tube, put it into a microwave reactor after being dissolved, set the reaction temperature to 100°C, and the reaction time to 15 minutes, turn on the microwave reactor, and stir.

[0029] After the reaction, transfer the reaction liquid to the distillation device, distill at normal pressure, collect the distillate acetic acid, evaporate to dryness, add 98g ethanol, transfer to the reflux condensation device, reflux for 10 minutes, cool, cool down to about 5°C, and suction filter, the obtained solid is 80°C Obtain 16.5g light yellow solid after vacuum drying for 2 hours, i.e. target compound diphenylmethane bismaleimide, its purity is 98.5% (HPLC), and yield is 92...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com