A tetraphenylethylene-benzophenone-carbazole derivative, crystal and its preparation method and application

A technology of carbazole derivatives and tetraphenylethylene, which is applied in the field of organic light-emitting materials, can solve the problems of restricting large-scale applications, reducing luminous intensity, and difficult preparation, etc., and achieves suppression of exciton annihilation, good luminous performance, and high luminous brightness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

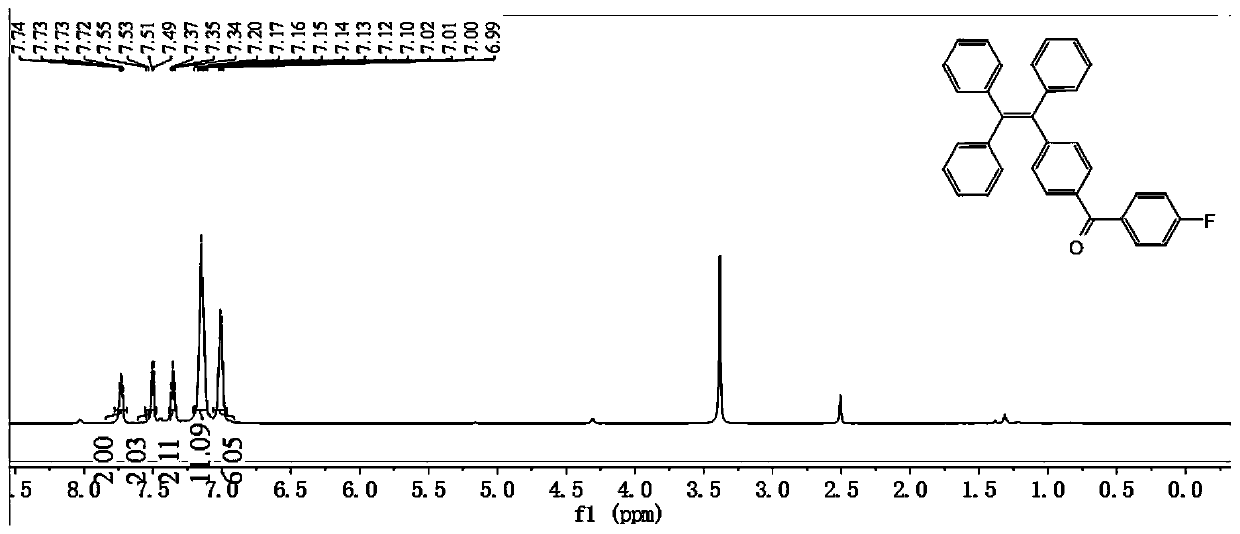

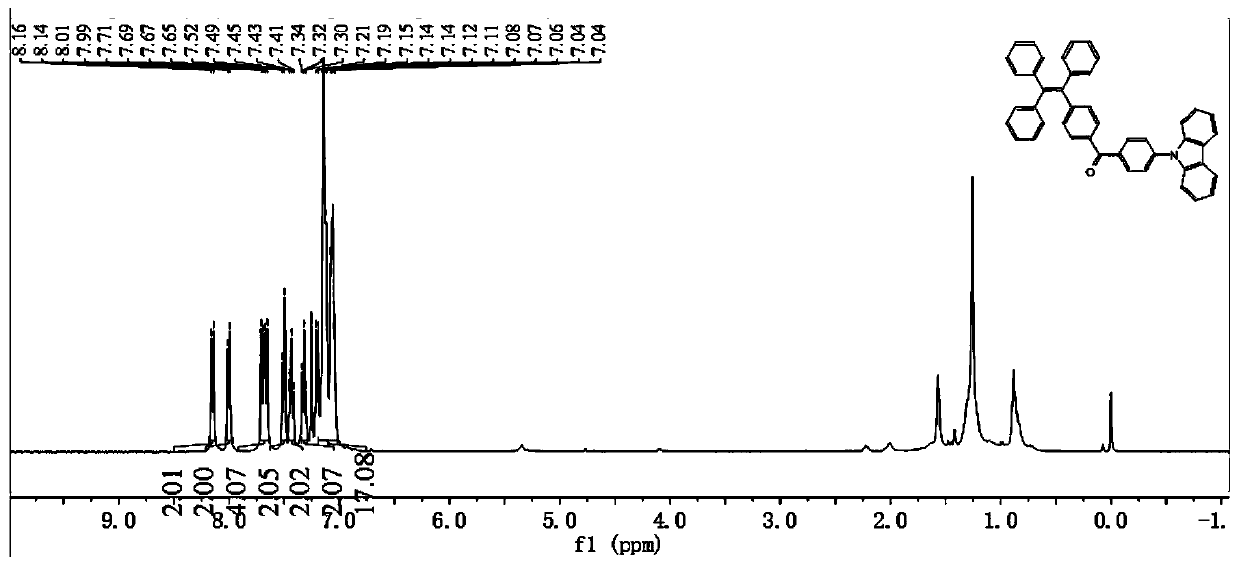

[0058] A tetraphenylethylene-benzophenone-carbazole derivative prepared by the following method:

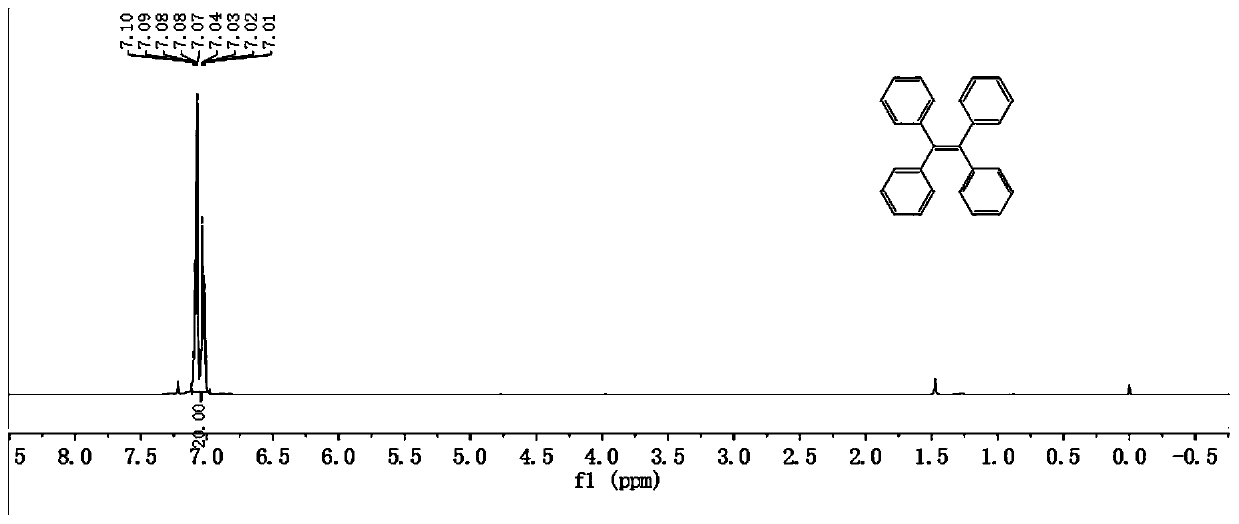

[0059] S1. Preparation of intermediate Ⅰ

[0060] A. Weigh 1.82g of benzophenone and 1.315g of zinc powder in a 250mL round bottom flask, add 150mL of anhydrous tetrahydrofuran to dissolve, and obtain a mixed solution;

[0061] B. Magnetically stir the mixed solution obtained in step A under the protection of nitrogen, cool to 0°C, inject 4.4mL of titanium tetrachloride, and stir in an ice bath for 30min (generally, the temperature of ice bath stirring can be -10~ 0 ℃, in embodiment 1 is-10 ℃), warm to room temperature, reflux 20h at 90 ℃, along with the carrying out of reaction, the color of reaction solution deepens gradually, turns black from light brown at the beginning, and reaction solution is opaque and turbid state;

[0062] C. After the reaction solution was cooled to room temperature, the reaction was quenched with 1:1 dilute hydrochloric acid (20 mL hydrochloric acid...

Embodiment 2

[0078] A tetraphenylethylene-benzophenone-carbazole derivative, the preparation method thereof is compared with the preparation method of Example 1, the difference is that the temperature of the ice-bath stirring in step S1. of Example 2 is -5 ° C, Time 60min, reflux heating time is 18h;

[0079] Other raw material consumption and operating steps are consistent with embodiment 1.

Embodiment 3

[0081] A kind of tetraphenylethylene-benzophenone-carbazole derivative, its preparation method is compared with the preparation method of embodiment 1, difference is, the time of Friedel-Crafts reaction in the step S2. of embodiment 3 is 5h; Step The temperature of heating and refluxing in S3. is 110°C, and the time is 12h;

[0082] Other raw material consumption and operating steps are consistent with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com