Vanadium complex based on acenaphthene quinone diimine ligand and preparation method and application of vanadium complex

A technology of acenaphthoquinone bisimine and vanadium complexes, which is applied in the preparation of vanadium complexes and the application field of olefin polymerization catalysts, and can solve the problems of large amounts of catalysts and co-catalysts, high molecular weight of catalytic products, and high degree of polymer branching. problem, to achieve the effect of high molecular weight, high product yield and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

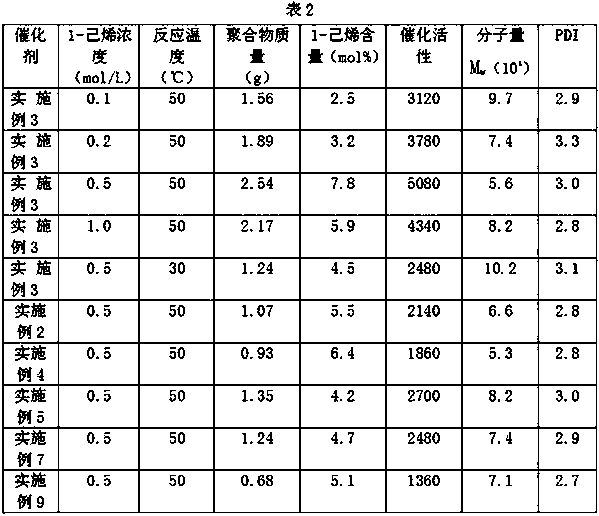

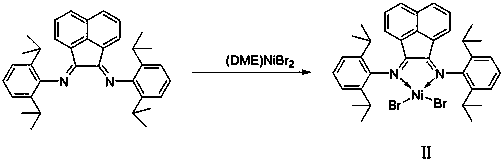

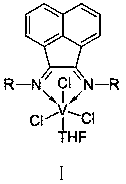

[0035] Preparation of vanadium complexes based on acenaphthoquinone bis-imine ligands, the structural formula of which is shown in formula I, R = 2,6-dimethylphenyl. Reaction scheme and concrete process are as follows:

[0036]

[0037] Under nitrogen protection, at room temperature, 20 mL of anhydrous toluene was added to the ligand 1,2-bis[(2,6-dimethylphenyl)imino]-acenaphthene (0.194 g, 0.5 mmol) to dissolve it, Then add VCl slowly 3 (THF) 3 (0.187 g, 0.5 mmol) in 10 mL of toluene, stirred for 12 hours. After the reaction, the liquid was concentrated to 5 mL under reduced pressure, 10 mL of hexane was added, filtered under nitrogen protection, the filter cake was washed twice with 2 mL of hexane, and 0.252 g of solid powder was obtained after vacuum drying with a yield of 82%. The elemental analysis formula is C 32 h 31 Cl 3 N 2 OV (%): C, 62.46; H, 5.22; N, 4.45.

Embodiment 2

[0039] Preparation of vanadium complexes based on acenaphthoquinone bis-imine ligands, the structural formula of which is shown in formula I, R = 2,6-diethylphenyl. Reaction scheme and concrete process are as follows:

[0040]

[0041] Under the protection of nitrogen, at room temperature, 20 mL of anhydrous toluene was added to the ligand 1,2-bis[(2,6-diethylphenyl)imino]-acenaphthene (0.222 g, 0.5 mmol) to dissolve it, Then add VCl slowly 3 (THF) 3 (0.187 g, 0.5 mmol) in 10 mL of toluene, stirred for 12 hours. After the reaction, the liquid was concentrated to 5 mL under reduced pressure, 10 mL of hexane was added, filtered under nitrogen protection, the filter cake was washed twice with 2 mL of hexane, and 0.272 g of solid powder was obtained after vacuum drying with a yield of 81%. The elemental analysis formula is C 36 h 39 Cl 3 N 2 OV (%): C, 64.03; H, 5.68; N, 4.06.

Embodiment 3

[0043] Preparation of vanadium complexes based on acenaphthoquinone bis-imine ligands, the structural formula of which is shown in formula I, R = 2,6-isopropylphenyl. Reaction scheme and concrete process are as follows:

[0044]

[0045] Under the protection of nitrogen, add 20 mL of anhydrous toluene to the ligand 1,2-bis[(2,6-diisopropylphenyl)imino]-acenaphthene (0.250 g, 0.5 mmol) at room temperature to dissolve it, Then add VCl slowly 3 (THF) 3 (0.187 g, 0.5 mmol) in 10 mL of toluene, stirred for 12 hours. Concentrate the liquid to 5 mL under reduced pressure, add 10 mL of hexane, filter under nitrogen protection, wash the filter cake twice with 2 mL of hexane, and obtain 0.316 g of solid powder after vacuum drying, with a yield of 87%. The elemental analysis formula is C 40 h 47 Cl 3 N 2 OV (%): C, 65.77; H, 6.60; N, 3.91.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com