Method for preparing degradable garbage bag with good mechanical performance

A garbage bag and performance technology, applied in the field of degradable garbage bag preparation, can solve the problems of unsustainable energy development, damage to soil permeability, and affect plant growth, etc., achieve good mechanical properties, improve the degree of agglomeration, and enhance soil vitality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

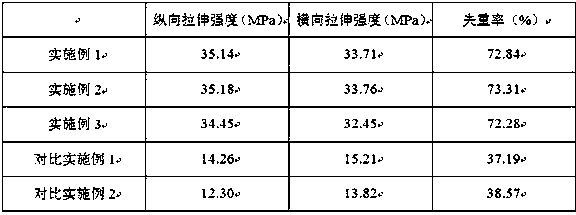

Examples

Embodiment 1

[0018] A method for preparing a degradable garbage bag with better mechanical properties, characterized in that it comprises the following steps:

[0019] (1) Take 5 parts by weight of fresh lotus leaves, wash them twice with clean water, place them at 40°C for 5 hours, then transfer them to a freeze-drying box, freeze-dry them for 6 hours, take them out, and grind them until they are granulated. diameter of 100 μm, then added to 10 times its volume of glacial acetic acid solution, boiled at 700 rpm for 10 minutes, filtered, then transferred to 10 times its volume of sodium hydroxide solution, sealed at 0.3 MPa for 4 hours, and then placed in Sonicate at 90°C for 20 minutes, filter, rinse with deionized water until neutral, and dry at 50°C;

[0020] (2) Add 4 parts of chitin fiber to 5 times its volume in deionized water, stir and dissolve at 70°C, then add the result of step (1), 2 parts of coupling agent, stir at 500rpm for 30min, then Put it into a freeze-drying box to fre...

Embodiment 2

[0029] A method for preparing a degradable garbage bag with better mechanical properties, characterized in that it comprises the following steps:

[0030] (1) Take 7 parts by weight of fresh lotus leaves, wash them with clean water for 3 times, place them at 42°C for 6 hours, then transfer them to a freeze-drying box, freeze-dry them for 7 hours, take them out, and grind them until they are granulated. diameter of 200 μm, then added to 15 times its volume of glacial acetic acid solution, boiled at 750rpm for 15 minutes, filtered, then transferred to 15 times its volume of sodium hydroxide solution, sealed at 0.32MPa for 5 hours, and then placed in Sonicate at 91°C for 25 minutes, filter, rinse with deionized water until neutral, and dry at 52°C;

[0031] (2) Add 5 parts of chitin fiber to 6 times its volume in deionized water, stir and dissolve at 71°C, then add the result of step (1), 3 parts of coupling agent, stir at 530rpm for 35min, then Put it into a freeze-drying box t...

Embodiment 3

[0040] A method for preparing a degradable garbage bag with better mechanical properties, characterized in that it comprises the following steps:

[0041] (1) Take 10 parts by weight of fresh lotus leaves, wash them three times with clean water, place them at 45°C for 7 hours, then transfer them to a freeze-drying box, freeze-dry them for 7 hours, take them out and grind them until they are granulated. diameter of 500 μm, then added to 20 times its volume of glacial acetic acid solution, boiled at 800 rpm for 20 min, filtered, then transferred to 20 times its volume of sodium hydroxide solution, sealed at 0.35 MPa for 5 hours, and then placed in Sonicate at 92°C for 30 minutes, filter, rinse with deionized water until neutral, and dry at 54°C;

[0042] (2) Add 6 parts of chitin fiber to 7 times its volume in deionized water, stir and dissolve at 72°C, then add the result of step (1), 3 parts of coupling agent, stir at 550rpm for 40min, then Put it into a freeze-drying box to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com