PEI-g-HBA prepolymer and vegetable protein composite modified adhesive as well as preparation method and application thereof

A plant protein and composite modification technology, applied in the field of wood adhesives, can solve the problems of poor initial viscosity and low water resistance, and achieve the effects of low manufacturing cost, high water resistance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of PEI-g-HBA prepolymer used below comprises the steps:

[0046] (1) In a reaction kettle equipped with a stirrer, under the protection of nitrogen bubbling, add polyethyleneimine (PEI), 3,4-dihydroxybenzaldehyde (DBA) and water, and add NaBH dropwise 3 CN, adjust the pH value to 5.0-6, react at room temperature for 6.5h, and stir evenly;

[0047] (2) The reaction is finished, and the product is taken, and a certain amount of dehydrated alcohol and water are used to wash 3 times until it is cleaned;

[0048] (3) The product obtained in step (2) was vacuum-dried at 50° C. for 24 hours, and discharged to obtain a PEI-g-HBA prepolymer.

[0049] The defatted vegetable protein meal powder used below is defatted soybean meal powder, which has a particle size of more than 100 mesh, a crude protein content of 33-45%, and sugars in varying amounts, which are commercially available.

Embodiment 1

[0051] A PEI-g-HBA prepolymer vegetable protein composite modified adhesive comprises the following components: 75Kg of tap water, 25Kg of defatted vegetable protein meal powder, and 1.3kg of PEI-g-HBA prepolymer.

[0052] The preparation method comprises the following steps:

[0053] S1: In a reaction kettle equipped with a stirrer, a thermometer and a condensing device, add water and defatted vegetable protein meal (powder) according to the proportion and stir evenly; the reaction is carried out at room temperature;

[0054] S2: Add PEI-g-HBA prepolymer according to the proportion and stir evenly to prepare vegetable protein mucilage;

[0055] S3: The obtained vegetable protein slime is processed through a colloid mill and a homogenizer, and the pressure of the homogenization processing is 25 MPa.

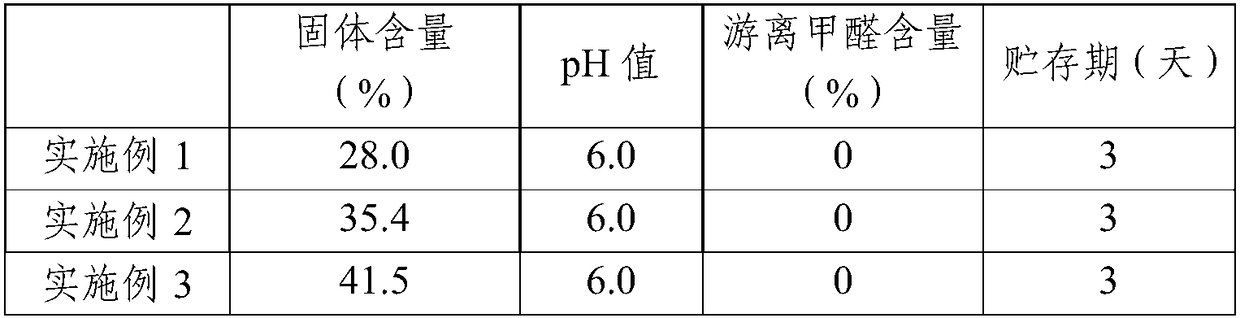

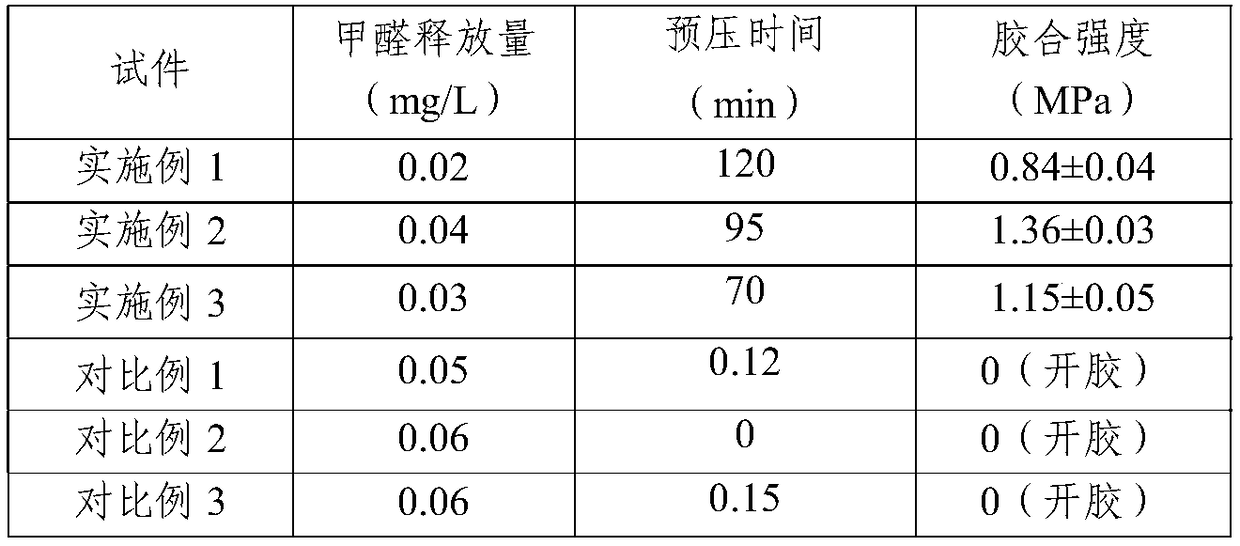

[0056] Three batches of parallel samples were prepared by the same process, and the performance and quality indicators of the obtained adhesives are shown in Table 1.

Embodiment 2

[0058] A PEI-g-HBA prepolymer vegetable protein composite modified adhesive comprises the following components: 65Kg of tap water, 30Kg of defatted vegetable protein meal powder, and 2.4kg of PEI-g-HBA prepolymer.

[0059] The preparation method is the same as in Example 1.

[0060] Three batches of parallel samples were prepared in the same way, and the performance and quality indicators of the prepared adhesive are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com