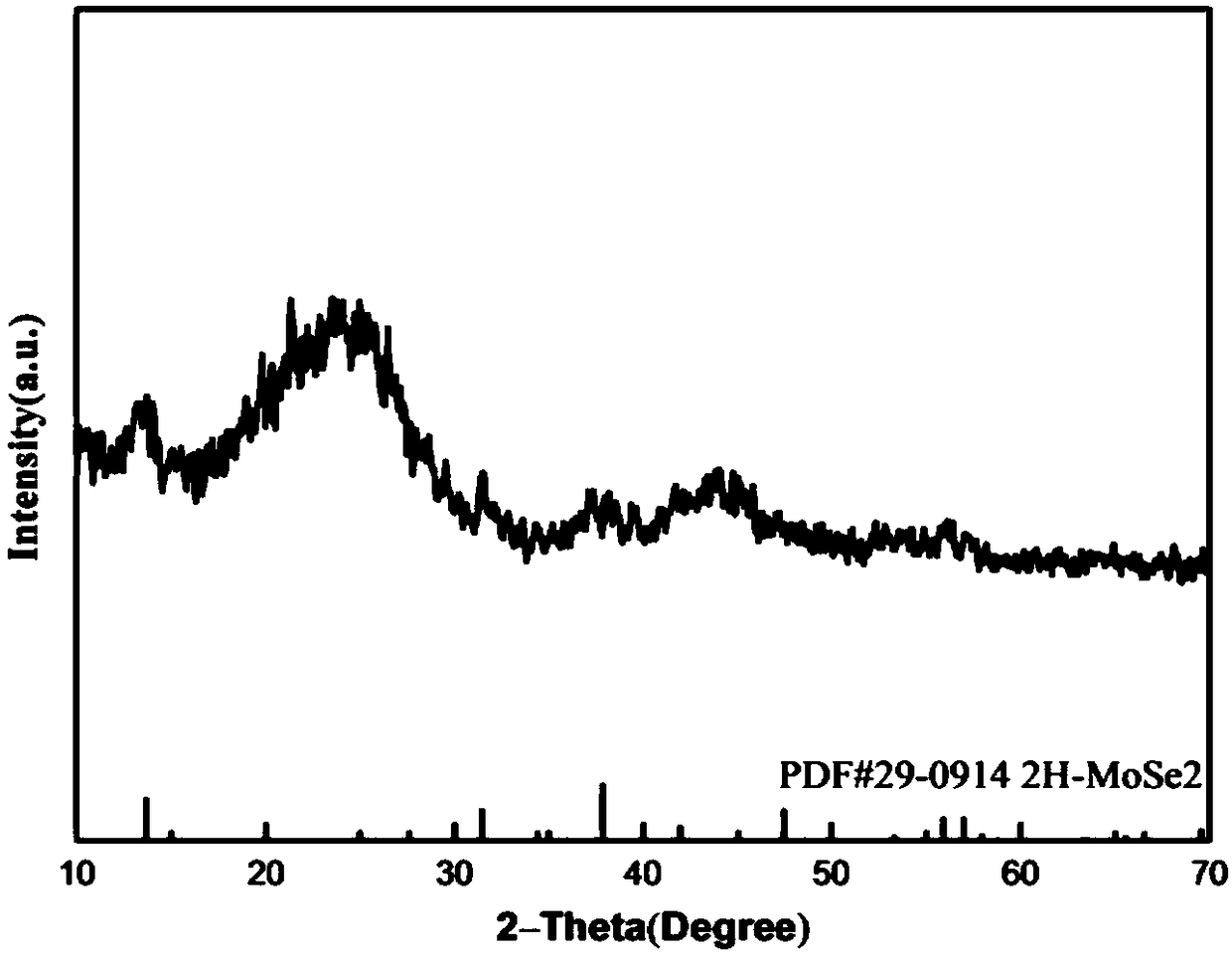

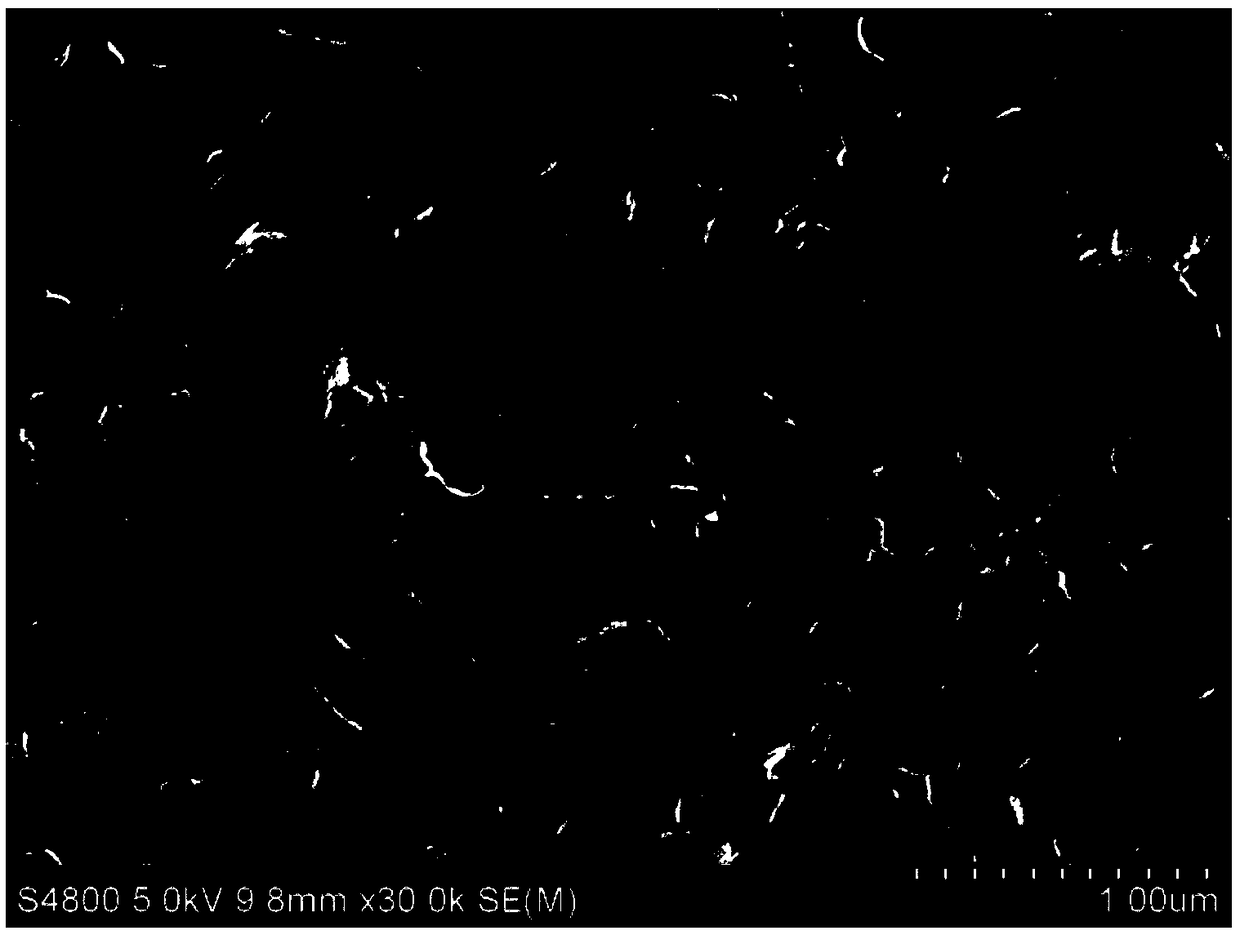

Preparation method of flaky molybdenum selenide/carbon fiber sheet composite material

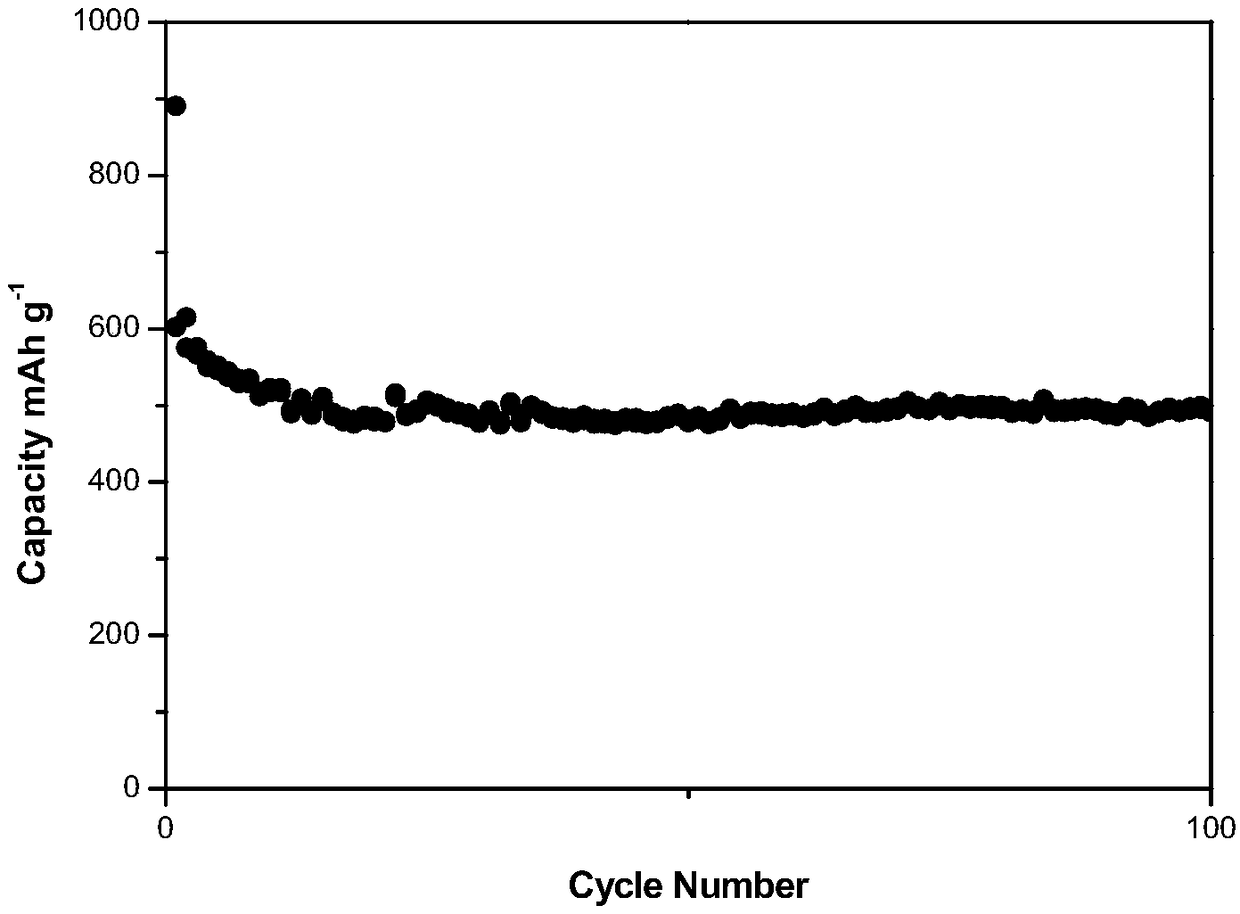

A technology of carbon fiber cloth and molybdenum diselenide, which is applied in the field of electrochemistry, can solve the problems of limited specific capacity and low energy density of pure carbon fiber, achieve the effects of improving structural stability and conductivity, simple experimental methods, and inhibiting agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of sheet molybdenum diselenide / carbon fiber cloth composite material of the present invention, comprises the steps:

[0029] 1) Dissolve selenium powder in 5-10 mL of hydrazine hydrate, and then undergo ultrasonic treatment to form 0.04-0.4 mmol mL -1 Solution A; wherein, the power of the ultrasonic generator is 300W, and the ultrasonic time is 1-5h.

[0030] Dissolve sodium molybdate in 20-40mL deionized water to form 0.006-0.03mmol mL -1 solution, and then add 1~5mL with a concentration of 0.04~0.4mmol mL -1 The acetic acid, obtains solution B;

[0031] The hydrophilic carbon cloth is subjected to anodic oxidation pretreatment, then washed and dried to obtain the treated hydrophilic carbon cloth;

[0032] 2) Mix solution A and solution B to form solution C, arrange the anodized hydrophilic carbon in solution C, ultrasonically treat, then perform hydrothermal reaction, then wash and dry to obtain molybdenum diselenide grown carbon fiber cloth...

Embodiment 1

[0036] 1) Dissolve selenium powder in 5mL of hydrazine hydrate, then sonicate for 2h under the condition of ultrasonic generator power of 300W to form 0.2mmol mL -1 Liquid A;

[0037] 2) Sodium molybdate was dissolved in 40 mL deionized water to form 0.03 mmol mL -1 liquid, then add 1mL to a concentration of 0.04mmol mL -1 The acetic acid, obtains solution B;

[0038] 3) The hydrophilic carbon cloth was anodized at 5V and 0.36A for 2 minutes, then washed with acetone, ethanol, and deionized water in sequence, and then dried;

[0039] 4) Mix liquid A and liquid B to form solution C, arrange the anodized hydrophilic carbon in solution C, ultrasonically treat for 2 hours under the condition of ultrasonic generator power of 300W, and then hydrothermally heat at 200°C After reacting for 12 hours, washing with ethanol and deionized water three times respectively, and then vacuum-drying at 60°C for 24 hours to obtain a carbon fiber cloth with molybdenum diselenide grown on it;

...

Embodiment 2

[0045] 1) Dissolve selenium powder in 10mL of hydrazine hydrate, and then sonicate for 1h under the condition of ultrasonic generator power of 200W to form 0.1mmol mL-1 Liquid A;

[0046] 2) Sodium molybdate was dissolved in 30 mL deionized water to form 0.01 mmol mL -1 liquid, then add 2mL concentration of 0.4mmol mL -1 The acetic acid, obtains solution B;

[0047] 3) The hydrophilic carbon cloth was anodized at 4V and 0.3A for 5 minutes, then washed with acetone, ethanol, and deionized water in sequence, and then dried;

[0048] 4) Mix liquid A and liquid B to form solution C, arrange the anodized hydrophilic carbon in solution C, ultrasonicate for 1 h under the condition of ultrasonic generator power of 200W, and then hydrothermally heat at 180°C After reacting for 24 hours, washing with ethanol and deionized water three times respectively, and then vacuum-drying at 60°C for 24 hours to obtain a carbon fiber cloth with molybdenum diselenide grown on it;

[0049] 5) Calci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com