Ultra-wideband and high-gain fiber and device fabrication technology

A high-gain fiber, gain fiber technology, applied in laser parts, lasers, electrical components, etc., can solve problems such as uncompact structure and complex pumping mechanism, achieve high luminous efficiency, avoid excess heat, and achieve tunable lasers output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

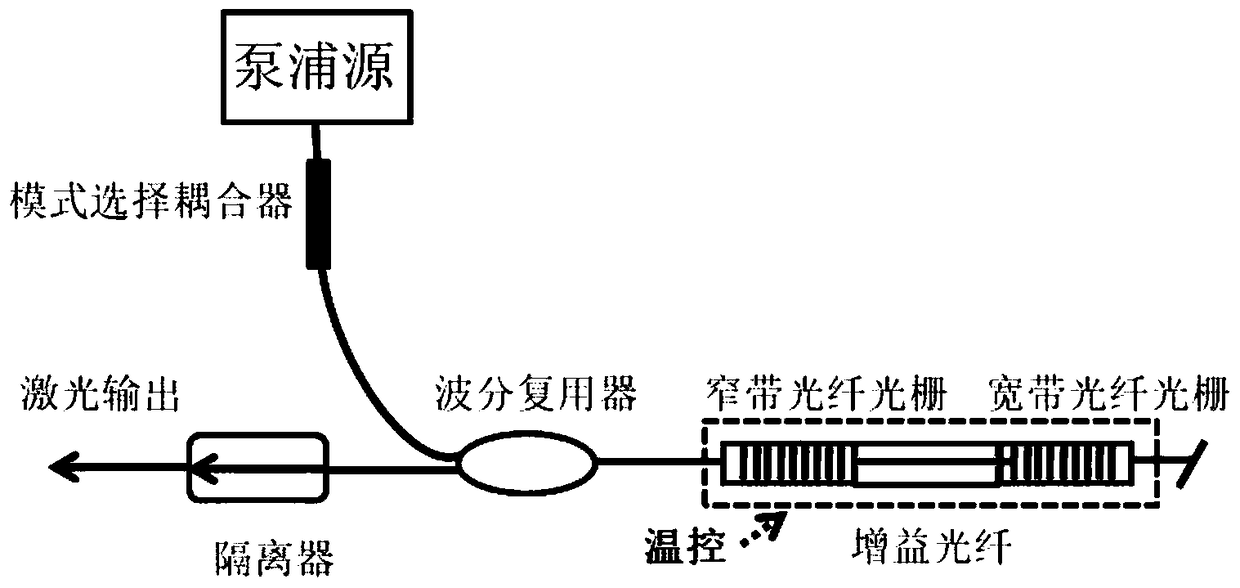

[0040] In this embodiment, an ultra-broadband high-gain optical fiber and device preparation technology includes the following steps:

[0041] (1) Preparation of gain fiber:

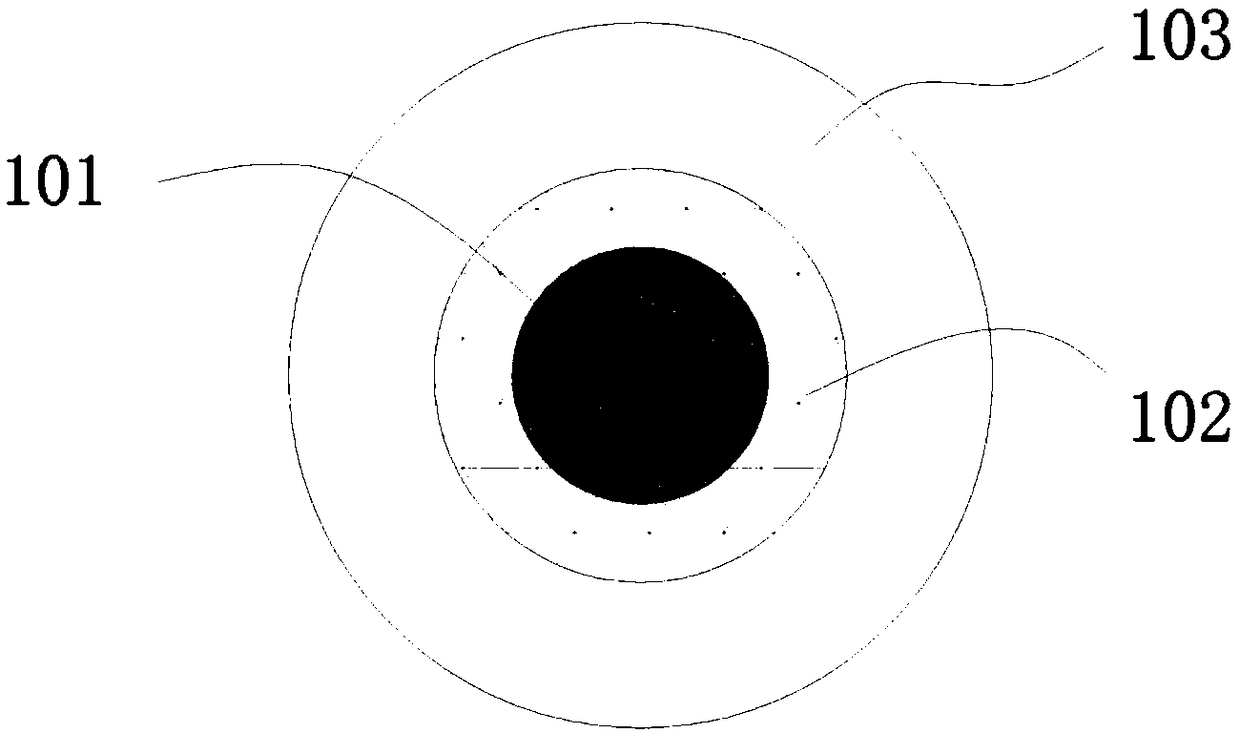

[0042] End face such as figure 1 As shown, the gain fiber is a fiber with a composite structure, including a core and a cladding 103 covering the surface of the core. The fiber core is composed of two rare earth ion doped regions 101 and 102 arranged in concentric circles. Wherein the rare earth ion doped region 101 is Er 3+ / Yb 3+ Doped multi-component silicate glass, the rare earth ion doped region 102 is Tm 3+ / Yb 3+ Doped multi-component germanate glass, the cladding layer 103 is multi-component germanate glass not doped with rare earth; Er 3+ 、Tm 3+ , Yb 3+ The doping concentrations are all >5wt%.

[0043] The gain fiber is prepared by a core melting drawing method, and the steps are as follows:

[0044] a. Glass melting: use the traditional melting-annealing method to melt Er respectively...

Embodiment 2

[0052] In this embodiment, an ultra-broadband high-gain optical fiber and device preparation technology includes the following steps:

[0053] (1) Preparation of gain fiber:

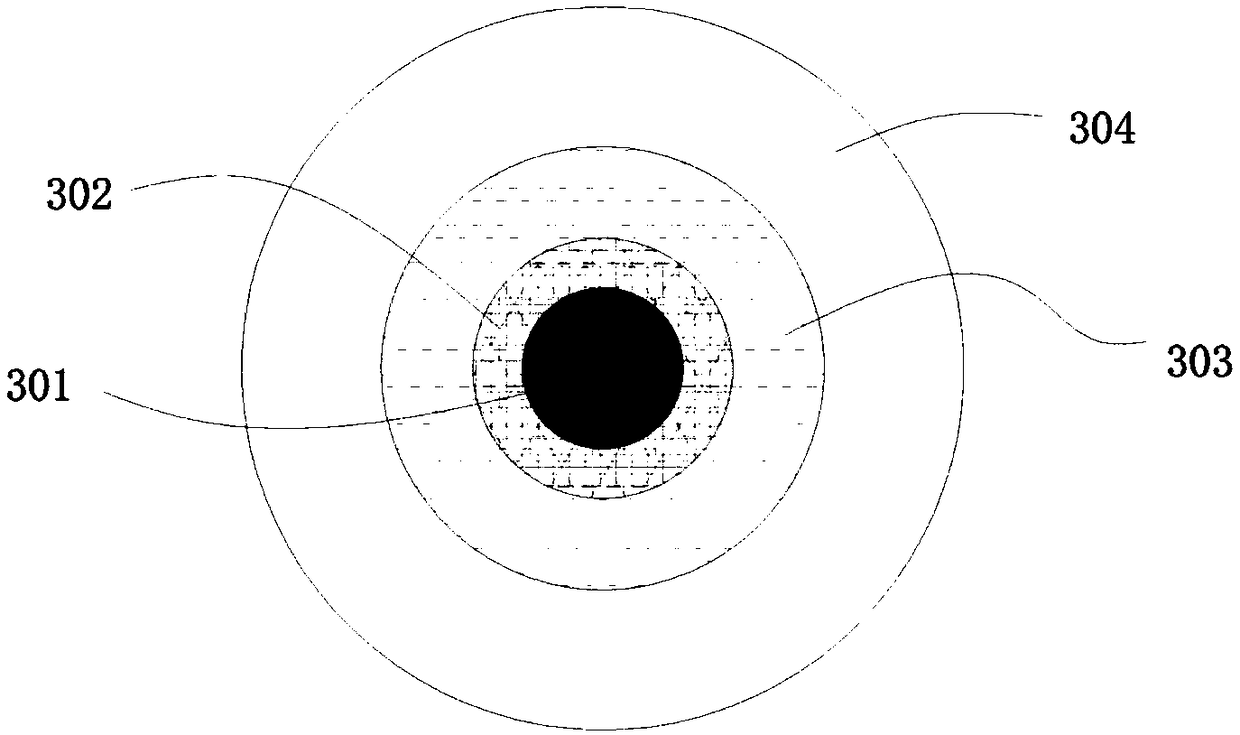

[0054] End face such as image 3 As shown, the gain fiber includes a core and a cladding 304 covering the surface of the core. The fiber core is composed of three rare earth ion doped regions 301 , 302 and 303 arranged in concentric circles. Wherein the rare earth ion doped region 301 is Er 3+ / Yb 3+ Doped multi-component germanate glass, the rare earth ion doped region 302 is Tm 3+ / Yb 3+ Doped multi-component germanate glass, the rare earth ion doped region 303 is Ho 3+ / Yb 3+ Doped multi-component germanate glass, the cladding layer 304 is multi-component germanate glass not doped with rare earth. Among them Er 3+ 、Tm 3+ 、Ho 3+ and Yb 3+ The doping concentrations are all >5wt%.

[0055] The gain fiber is prepared by the tube-and-rod method, and the steps are as follows:

[0056] a. Glass...

Embodiment 3

[0064] In this embodiment, an ultra-broadband high-gain optical fiber and device preparation technology includes the following steps:

[0065] (1) Preparation of gain fiber:

[0066] End face such as Figure 4 As shown, the gain fiber includes a core and a cladding 403 covering the surface of the core. The fiber core is composed of two rare earth ion doped regions 401 and 402 arranged in a symmetrical sector. Wherein the rare earth ion doped region 401 is Er 3+ / Yb 3+ Doped multi-component tellurite glass, the rare earth ion doped region 402 is Tm 3 + / Yb 3+ Doped multi-component tellurite glass, the cladding 403 is multi-component tellurite glass not doped with rare earth; Er 3+ 、Tm 3+ , Yb 3+ The doping concentrations are all >5wt%.

[0067] The gain fiber is prepared by the tube-and-rod method, and the steps are as follows:

[0068] a. Glass melting: use the traditional melting-annealing method to melt Er respectively 3+ / Yb 3+ and Tm 3+ / Yb 3+ Doped bulk cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gain coefficient | aaaaa | aaaaa |

| Gain coefficient | aaaaa | aaaaa |

| Gain coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com