Ion hybridization porous material and preparation method and applications thereof

A porous material and hybridization technology, applied in separation methods, chemical instruments and methods, organic chemistry, etc., can solve the problems of difficult design and preparation, achieve remarkable removal effect, simple preparation method, and good acetylene capture capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add 1mmol 4,4’-bipyridine disulfide in 20ml methanol solution dropwise to 0.5 mmol(NH 4 ) 2 GeF 6 And 0.5mmol Cu(BF 4 ) 2 In 10ml aqueous solution, magnetically stirred at room temperature for 24h, and after suction filtration, the product was soaked in methanol for 24h to obtain GeFSIX-S-Cu-i ion hybrid porous material.

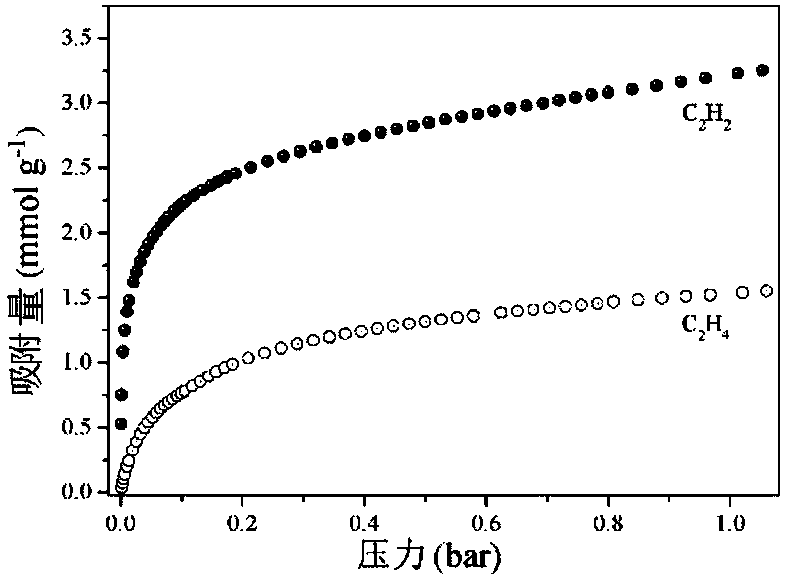

[0039] The adsorption isotherm of GeFSIX-S-Cu-i for acetylene and ethylene at 298K is as figure 1 As shown; the XRD data graph is as figure 2 Shown.

[0040] Load the obtained GeFSIX-S-Cu-i ion hybrid porous material into a 5cm long adsorption column, and pass the ethylene:acetylene (volume ratio 99:1) mixed gas 1.0ml / min into the adsorption column of the embodiment at 25°C , To obtain high-purity ethylene gas (greater than 99.999%), when the acetylene penetrates, stop the adsorption, and purge the adsorption column with He gas for 18h, the adsorption column can be recycled.

Embodiment 2

[0042] Add 0.85mmol of 4,4'-bipyridine disulfide in ethanol and ethylene glycol (1:1) solution dropwise to 0.3mmol of NiTiF 6 The reaction was carried out at 65°C for 12h in the aqueous solution, and the product obtained was filtered and washed with suction to obtain TIFSIX-S-Ni-i ion hybrid porous material.

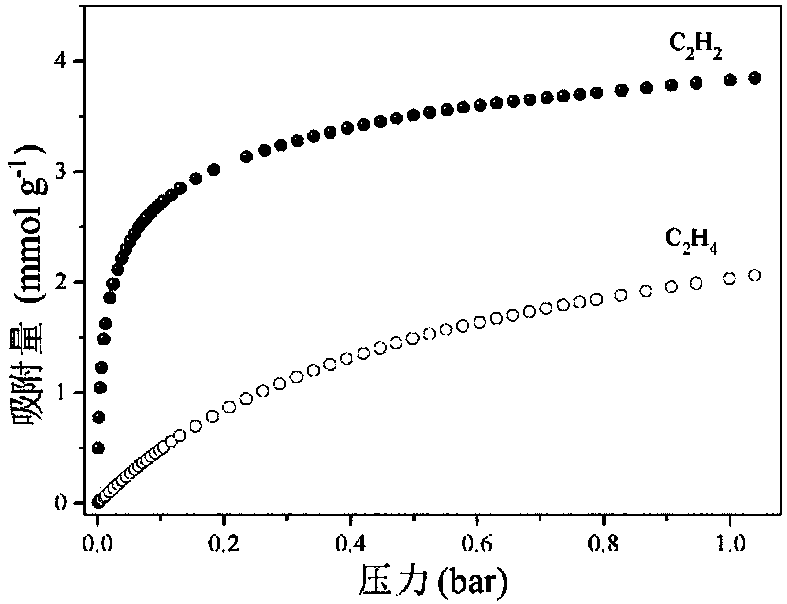

[0043] The crystal structure diagram of TIFSIX-S-Ni-i is as follows image 3 As shown; the XRD data graph is as Figure 4 Shown.

Embodiment 3

[0045] Add 1mmol 4,4’-bipyridinedisulfide in 20ml methanol solution dropwise to 0.5mmol CuZrF 6 In 20ml methanol solution, magnetically stirred at room temperature for 24h, and after suction filtration, the product obtained was soaked in methanol for 24h to obtain the ZrFSIX-S-Cu-i ion hybrid porous material.

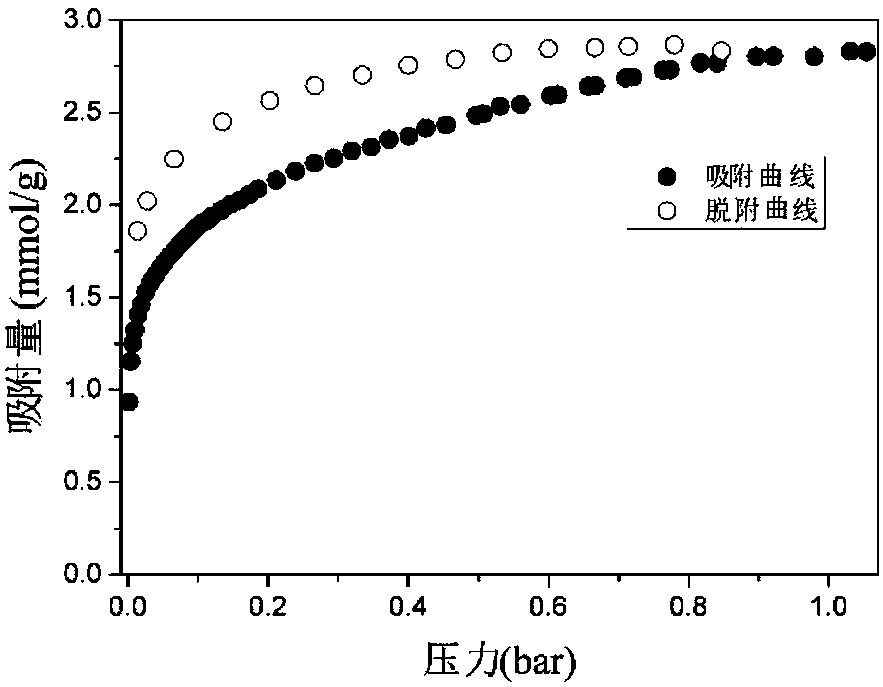

[0046] The adsorption and desorption isotherm of acetylene by ZrFSIX-S-Cu-i at 273K is as Figure 5 Shown.

[0047] Load the obtained ZrFSIX-S-Cu-i ion hybrid porous material into a 10cm long adsorption column, and pass 1.0ml / min of ethylene:acetylene (volume ratio 50:50) mixed gas into the adsorption column of the embodiment at 25°C , To obtain high-purity ethylene gas (greater than 99.99%), when the acetylene penetrates, stop the adsorption. The adsorption column adopts vacuum desorption to obtain acetylene gas with a purity greater than 90%, and the adsorption column can be recycled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com