Method for preparing hericium erinaceus oligosaccharide on basis of film separation technology

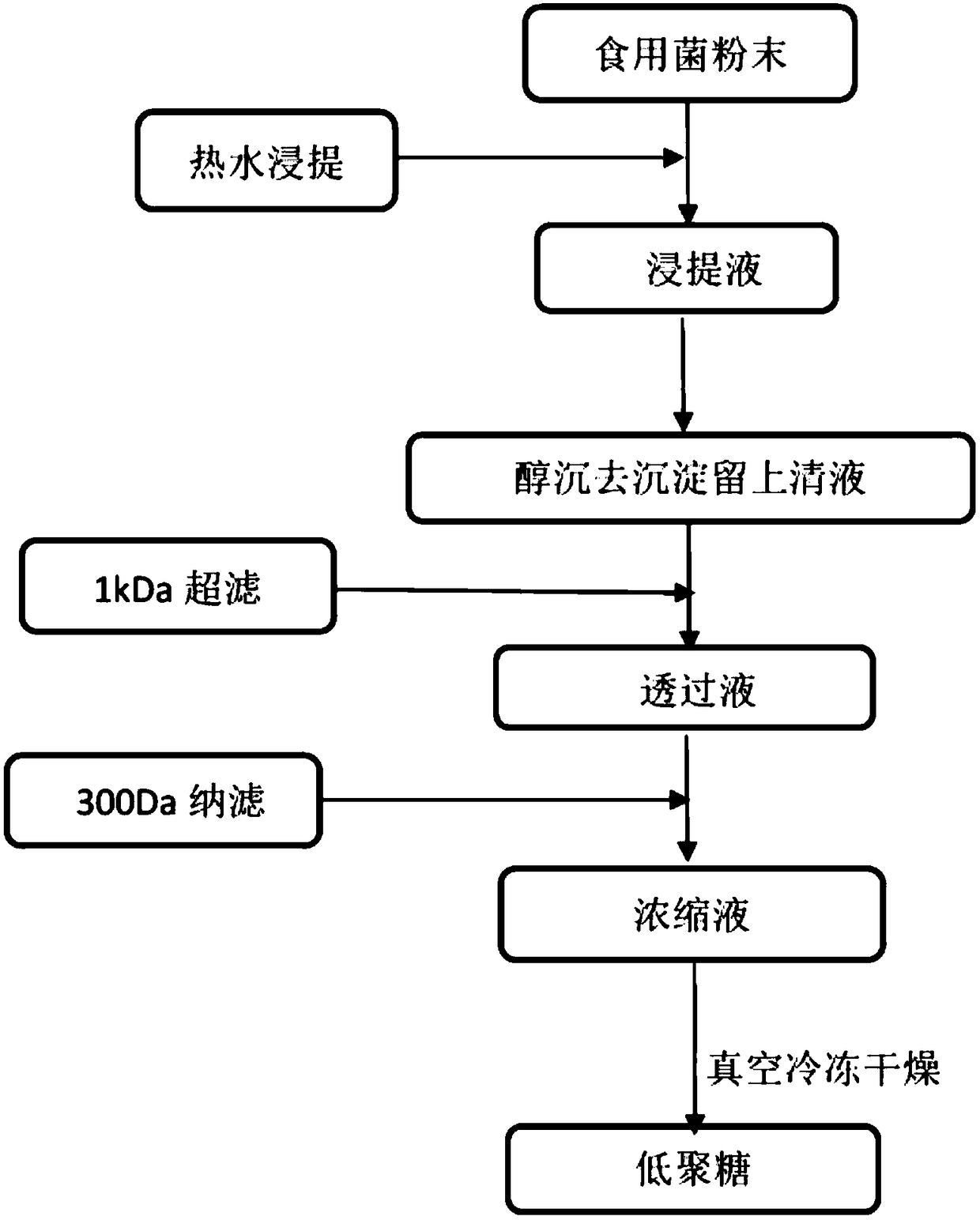

A technology of Hericium erinaceus and oligosaccharide, which is applied in the field of efficient preparation of Hericium erinaceus oligosaccharides based on membrane separation technology, can solve many problems such as the research on the preparation process of oligosaccharides, and achieves low cost, short production cycle and high purity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Add 100g of Hericium erinaceus powder into distilled water according to the mass ratio of material to liquid 1:20, extract at 70°C for 2h, filter with suction, repeat the extraction of the filter residue once, combine the filtrate obtained from the two extractions, and concentrate under reduced pressure to 1 / 4 of the original volume to obtain a concentrated solution, mix the obtained concentrated solution with 90% ethanol aqueous solution at a volume ratio of 1:3 for alcohol precipitation, and collect the supernatant;

[0042] (2) Place the supernatant of step (1) gained in the feed liquid tank of the high-pressure flat membrane machine, then put the PES ultrafiltration membrane of 1000Da in the high-pressure flat membrane machine, seal the oxygen barrier, at pressure 1MPa, rotating speed 600r Ultrafiltration at 1 / min, when the raw material liquid is concentrated to 1 / 4 of the original volume after ultrafiltration, add water to dilute 1 times and repeat the ultrafilt...

Embodiment 2

[0046] (1) Add 100 g of Hericium erinaceus powder into distilled water according to the mass ratio of material to liquid at 1:20, extract at 60°C for 3 hours, filter with suction, repeat the extraction of the filter residue once, combine the filtrate obtained from the two extractions, and concentrate under reduced pressure to 1 / 4 of the original volume to obtain a concentrated solution, mix the obtained concentrated solution with an ethanol aqueous solution with a volume fraction of 80% at a volume ratio of 1:3 for alcohol precipitation, and collect the supernatant;

[0047] (2) Place the supernatant of step (1) gained in the feed liquid tank of the high-pressure flat membrane machine, then put the PA ultrafiltration membrane of 1000Da in the high-pressure flat membrane machine, seal the oxygen barrier, at pressure 1MPa, rotating speed 600r Ultrafiltration at 1 / min, when the raw material liquid is concentrated to 1 / 4 of the original volume after ultrafiltration, add water to di...

Embodiment 3

[0051] (1) Add 100 g of Hericium erinaceus powder into distilled water according to the mass ratio of material to liquid at 1:20, extract at 80°C for 1 hour, filter with suction, repeat the extraction of the filter residue once, combine the filtrate obtained from the two extractions, and concentrate under reduced pressure to 1 / 4 of the original volume to obtain a concentrated solution, mix the obtained concentrated solution with an ethanol aqueous solution with a volume fraction of 95% at a volume ratio of 1:3 for alcohol precipitation, and collect the supernatant;

[0052] (2) Place the supernatant of step (1) gained in the feed liquid tank of the high-pressure flat membrane machine, then put the PES ultrafiltration membrane of 2000Da in the high-pressure flat membrane machine, seal the oxygen barrier, at pressure 1MPa, rotating speed 600r Ultrafiltration at 1 / min, when the raw material liquid is concentrated to 1 / 4 of the original volume after ultrafiltration, add water to di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com