Epoxy resin sealant and preparation method and application thereof

A technology of epoxy resin and sealant, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problem of low bonding strength, achieve the effects of reducing viscosity, meeting production needs, and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

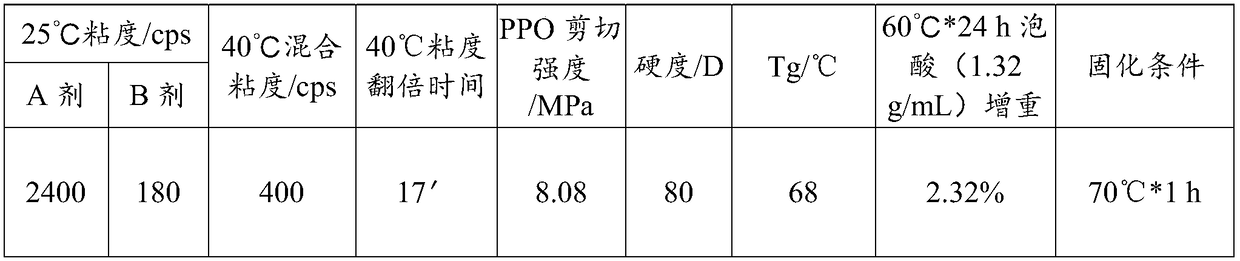

Embodiment 1

[0025] As an embodiment of the epoxy resin sealant of the present invention, the epoxy resin sealant described in this embodiment is composed of A component and B component, and the A component includes the following components by weight: bis 79.5 parts of phenol F type epoxy resin, 8.5 parts of bisphenol A type epoxy resin, 1 part of silane coupling agent KH-560 and 11 parts of difunctional epoxy thinner; the B component includes the following parts by weight: 30 parts of polyetheramine, 28 parts of 2,4,6-tris(dimethylaminomethyl)phenol (DMP-30), 2,4,6-tris(dimethylaminomethyl)phenolate (DMP-30 salt ) 25 parts and 17 parts of benzyl alcohol.

[0026] The preparation method of epoxy resin sealant described in the present embodiment may further comprise the steps:

[0027] (1) Preparation of component A: first add bisphenol F epoxy resin and bisphenol A epoxy resin into the stirring tank, stir evenly, then add bifunctional epoxy diluent and KH-560, with 1000~ After dispersing...

Embodiment 2

[0035] As an embodiment of the epoxy resin sealant of the present invention, the epoxy resin sealant described in this embodiment is composed of A component and B component, and the A component includes the following components by weight: bis 78 parts of phenol F type epoxy resins, 8 parts of bisphenol A type epoxy resins, 1.1 parts of silane coupling agent KH-560 and 12.9 parts of difunctional epoxy diluents; the B component includes the following parts by weight: 35 parts of polyetheramine, 25 parts of DMP-30, 25 parts of DMP-30 salt and 15 parts of benzyl alcohol.

[0036] The preparation method of epoxy resin sealant described in the present embodiment may further comprise the steps:

[0037] (1) Preparation of component A: first add bisphenol F epoxy resin and bisphenol A epoxy resin into the stirring tank, stir evenly, then add bifunctional epoxy diluent and KH-560, with 1000~ After dispersing for 15-20 minutes at a speed of 1200r / min, vacuum defoaming, vacuum degree -0...

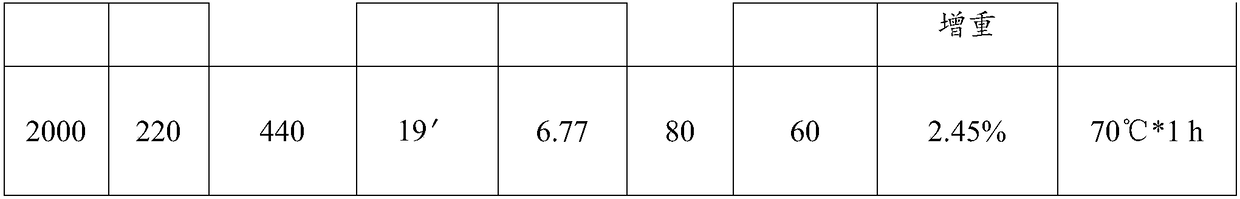

Embodiment 3

[0045] As an embodiment of the epoxy resin sealant of the present invention, the epoxy resin sealant described in this embodiment is composed of A component and B component, and the A component includes the following components by weight: bis 77 parts of phenol F type epoxy resin, 7 parts of bisphenol A type epoxy resin, 1 part of silane coupling agent KH-560 and 15 parts of difunctional epoxy thinner; the B component includes the following parts by weight: 33 parts of polyetheramine, 30 parts of DMP-30, 20 parts of DMP-30 salt and 17 parts of benzyl alcohol.

[0046] The preparation method of epoxy resin sealant described in the present embodiment may further comprise the steps:

[0047] (1) Preparation of component A: first add bisphenol F epoxy resin and bisphenol A epoxy resin into the stirring tank, stir evenly, then add bifunctional epoxy diluent and KH-560, with 1000~ After dispersing for 15-20 minutes at a speed of 1200r / min, vacuum defoaming, vacuum degree -0.098-0.1MP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com