Preparation method and application of SnO2 hollow nanospheres of different sizes

A hollow nano-sized technology, applied in the field of nano-materials, can solve the problems of time-consuming and cumbersome processes, and achieve the effects of reducing the number of washings, drying quickly, and increasing the yield and morphological yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 0.182gK 2 SnO 3 ·3H 2 O and 0.24g of urea were dissolved in 40ml of ultrapure water, then transferred to a 50ml polytetrafluoroethylene lining, and the polytetrafluoroethylene lining was installed in the autoclave, and the autoclave was sealed to adjust The temperature is at 190°C, heated for 15 hours, cooled naturally, the product obtained is washed with water and absolute ethanol for 6 times in sequence, and then dried under vacuum at 50°C.

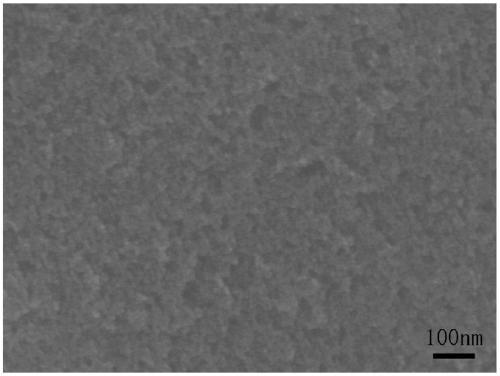

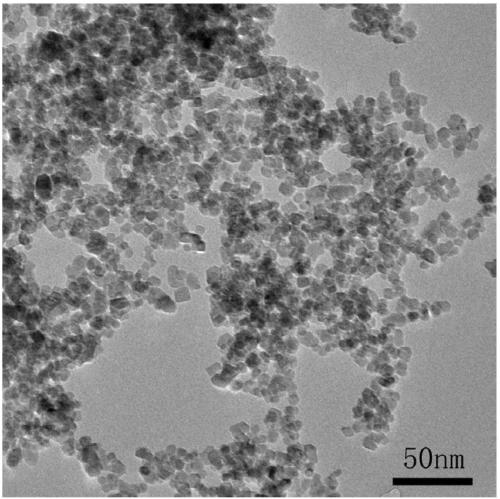

[0036] The product obtained in Example 1 is characterized, and the results are as follows figure 1 , figure 2 as shown, figure 1 SnO prepared for this example 2 Scanning electron micrograph of hollow nanospheres, figure 2 SnO prepared for this embodiment 2 TEM image of hollow nanospheres. Transmission electron microscope test shows that the SnO prepared by this embodiment 2 The hollow nanospheres have a diameter of 6.8 nm.

Embodiment 2

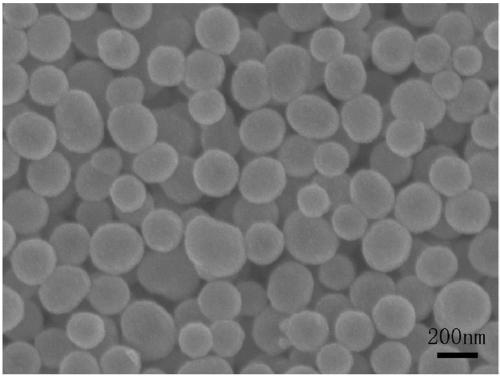

[0038] 0.182g K 2 SnO 3 ·3H 2 O and 0.24 g of urea were dissolved in a mixed solution made of 5 ml of absolute ethanol and 35 ml of ultrapure water, and then transferred to a 50 ml polytetrafluoroethylene lining, and the polytetrafluoroethylene lining was placed on In the high-pressure reaction kettle, seal the high-pressure reaction kettle and adjust its temperature at 190°C, heat for 15h, and cool naturally. The obtained product is washed with water and absolute ethanol for 6 times, and then vacuum-dried at 50°C to obtain SnO with a diameter of 8.1nm. 2 nano hollow spheres.

Embodiment 3

[0040] 0.182g K 2 SnO 3 ·3H 2 O and 0.24g of urea were respectively dissolved in a mixed solution made of 10ml of absolute ethanol and 30ml of ultrapure water, and then transferred to a 50ml polytetrafluoroethylene lining, and the polytetrafluoroethylene lining was placed in a high-pressure In the reaction kettle, seal the autoclave and adjust its temperature at 190°C, heat for 15h, and cool naturally. The obtained product is washed with water and absolute ethanol for 6 times in turn, and then vacuum-dried at 50°C to obtain SnO with a diameter of 11.3nm. 2 nano hollow spheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com