Laser preparation method of CoOOH nanosheet with rich oxygen vacancies

A nanosheet and vacancy technology, applied in the field of materials, can solve the problems of reducing the catalytic activity, high energy consumption and danger of materials, and achieve the effects of improving catalytic activity and conductivity, reducing energy consumption and danger, and reducing by-products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

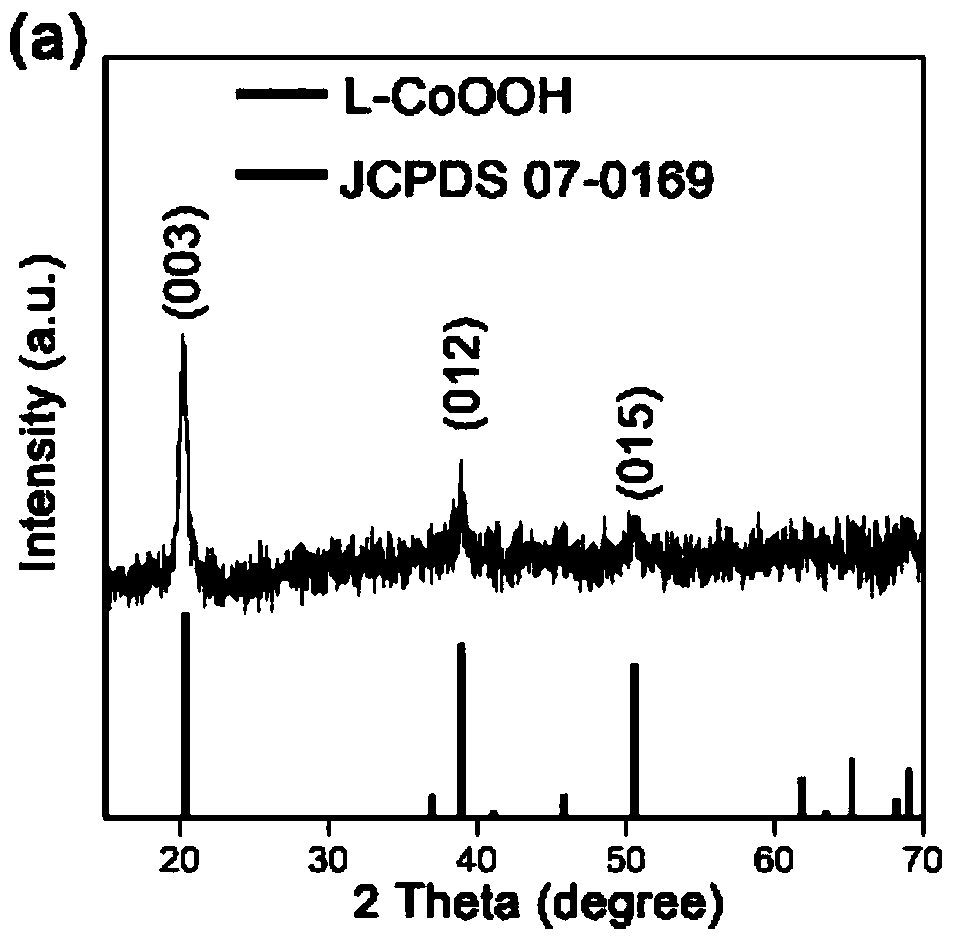

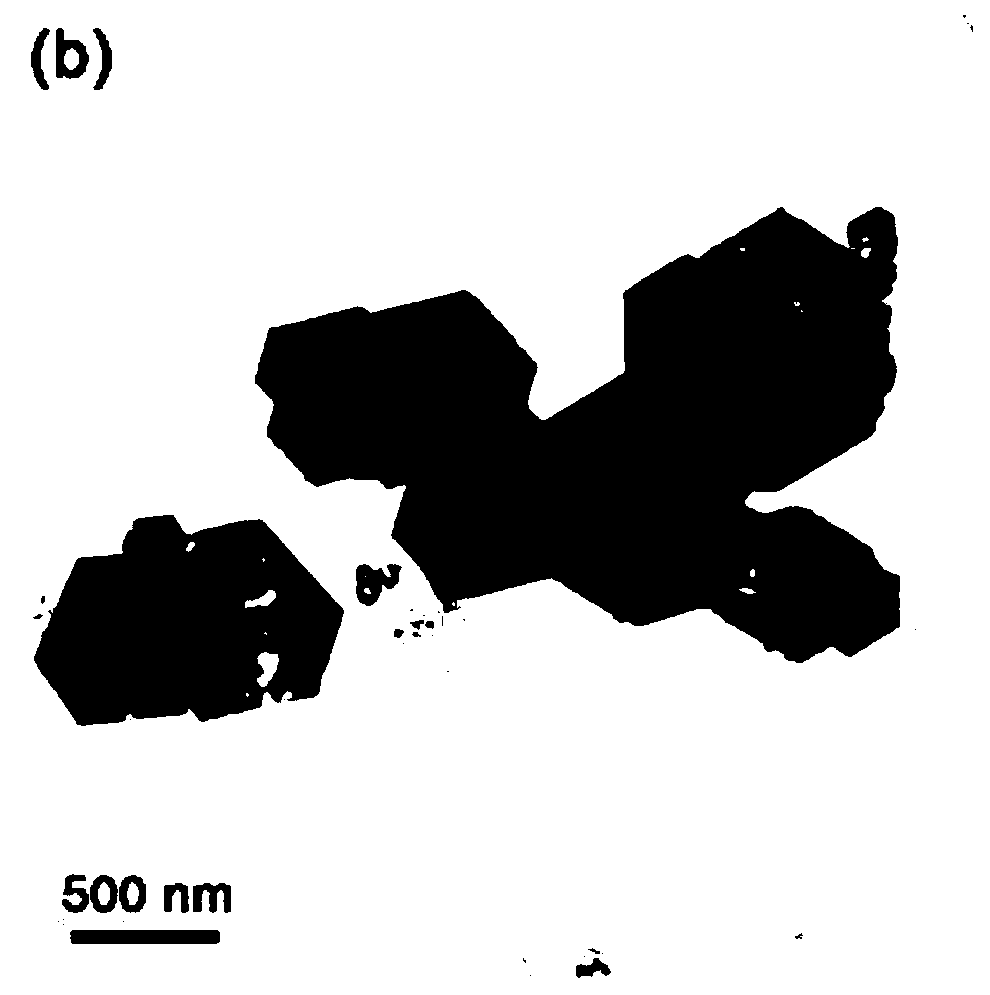

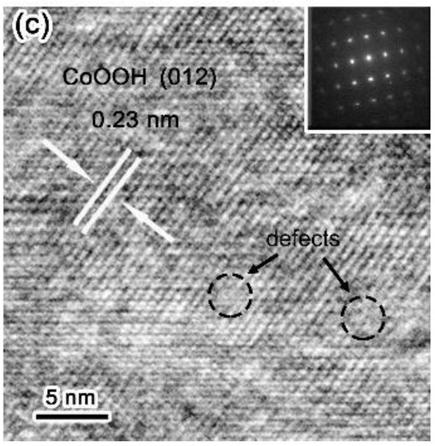

[0022] The invention provides a laser preparation method of CoOOH nanosheets rich in oxygen vacancies, the method comprising: laser preparation of CoOOH nanosheets rich in oxygen vacancies uses a nanosecond pulse laser Nimma-600 with a pulse width of 7 ns. Firstly, the metal cobalt target was polished and cleaned several times, and then the cobalt target was placed in a pre-prepared 1M KOH aqueous solution, and irradiated with a nanosecond laser at room temperature for 20 minutes until the solution turned into a brown sol. Finally, the obtained product was washed with deionized water several times and then freeze-dried for 24 h to obtain CoOOH nanosheets with rich oxygen vacancies. Phase characterization such as Figure 1-3 shown, from Figure 1-3 It can be seen that the phase and oxygen vacancies of the product obtained by the method of the present invention exist.

[0023] The invention utilizes the laser method to create vacancies to solve the dangerous defects of high te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com