Environment-friendly coiled tubing drag reducing agent

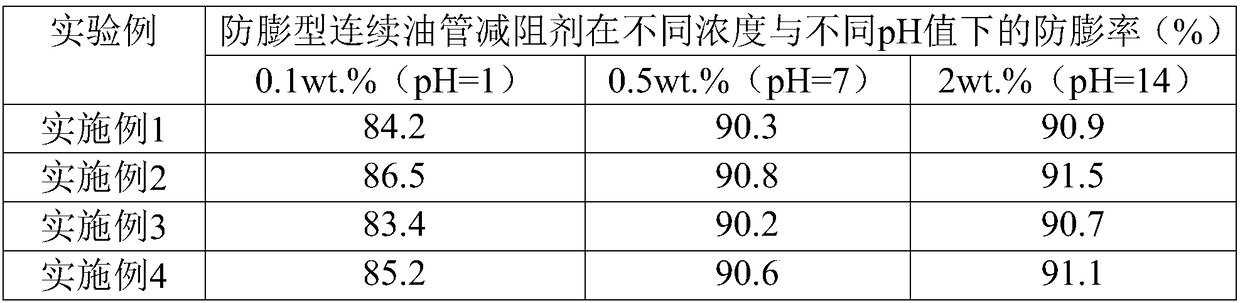

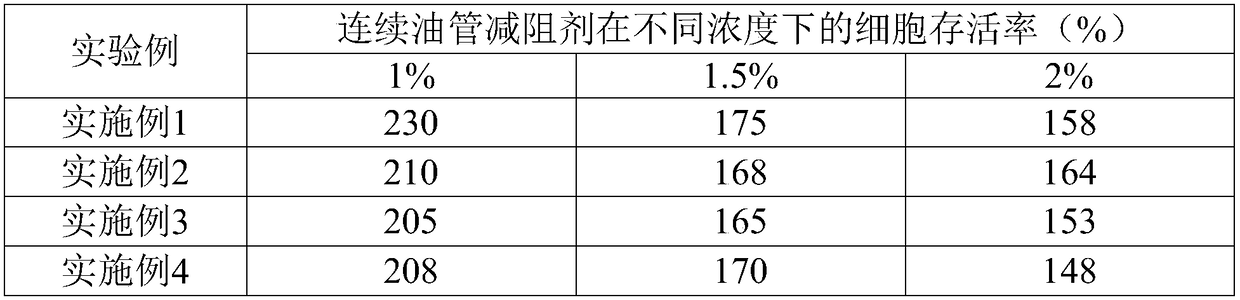

An environment-friendly, drag-reducing agent technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of swelling and migration, formation pollution damage, reduce the self-locking degree of coiled tubing, etc., and achieve high anti-swelling Performance, effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] An environment-friendly coiled tubing drag reducer, the specific preparation method is as follows:

[0019] S1. Mix 330g of triethanolamine and 60mL of water evenly, raise the temperature to 50°C, add 270g of benzyl chloride dropwise within 1 hour, raise the temperature to 75°C, and continue the reaction for 4 hours to obtain a clay stabilizer;

[0020] S2, measure 60mL of clear water, under the condition of high-speed stirring (stirring speed 10000r / min), add 15g Tween-80, stirring time is 5min, add 5g Swire oil, stir for 15min, add 10g ethylene glycol and 10g prepared in step S1 Clay stabilizer, stirred for 5 minutes to obtain an environment-friendly coiled tubing drag reducer.

Embodiment 2

[0022] An environment-friendly coiled tubing drag reducer, the specific preparation method is as follows:

[0023] S1. Mix 330g of triethanolamine and 100mL of water evenly, raise the temperature to 70°C, add 300g of benzyl chloride dropwise within 2 hours, raise the temperature to 110°C, and continue the reaction for 8h to obtain a clay stabilizer;

[0024] S2. Measure 25mL of clear water, under high-speed stirring, add 20g of isomeric tridecyl alcohol polyoxyethylene ether, stirring time is 5min, add 15g of Swire oil, stir for 15min, add 20g of ethylene glycol and 20g of the clay stabilizer prepared in step S1 , and stirred for 5 minutes to obtain an environment-friendly coiled tubing drag reducer.

Embodiment 3

[0026] An environment-friendly coiled tubing drag reducer, the specific preparation method is as follows:

[0027] S1. Mix 360g of triethanolamine and 60mL of water evenly, raise the temperature to 60°C, add 270g of benzyl chloride dropwise within 2 hours, raise the temperature to 100°C, and continue the reaction for 6h to obtain a clay stabilizer;

[0028] S2. Measure 25mL of clear water, stir at high speed (stirring speed 10000r / min), add 40g of isomeric tridecyl alcohol polyoxyethylene ether, stir for 5min, add 10g of swire oil, stir for 15min, add 10g of ethylene glycol and 15g of The clay stabilizer prepared in step S1 was stirred for 5 minutes to obtain an environment-friendly coiled tubing drag reducer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap