SiC knot barrier Schottky diode and manufacturing method thereof

A technology of junction barrier Schottky and manufacturing method, which is applied in the field of SiC junction barrier Schottky diodes and its manufacture, and can solve problems such as high diode conduction voltage, low electron penetration rate, and increased conduction resistance , to achieve the effect of accurately changing the effective barrier height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

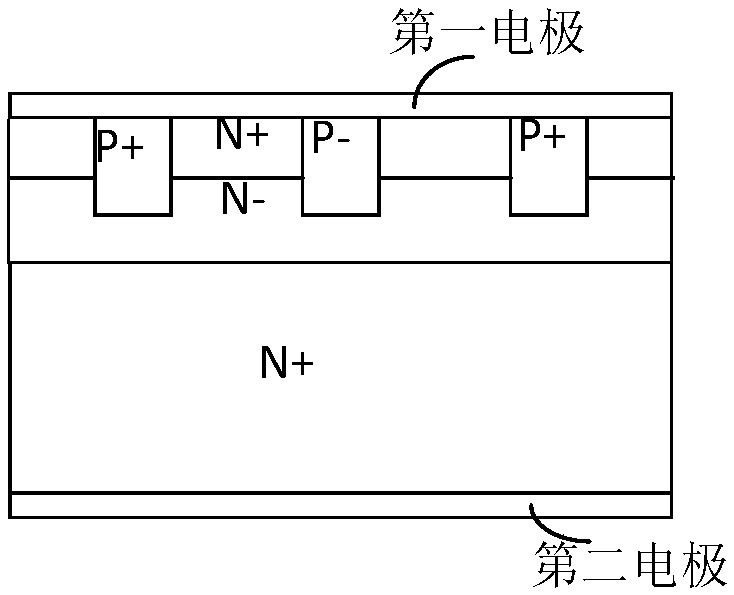

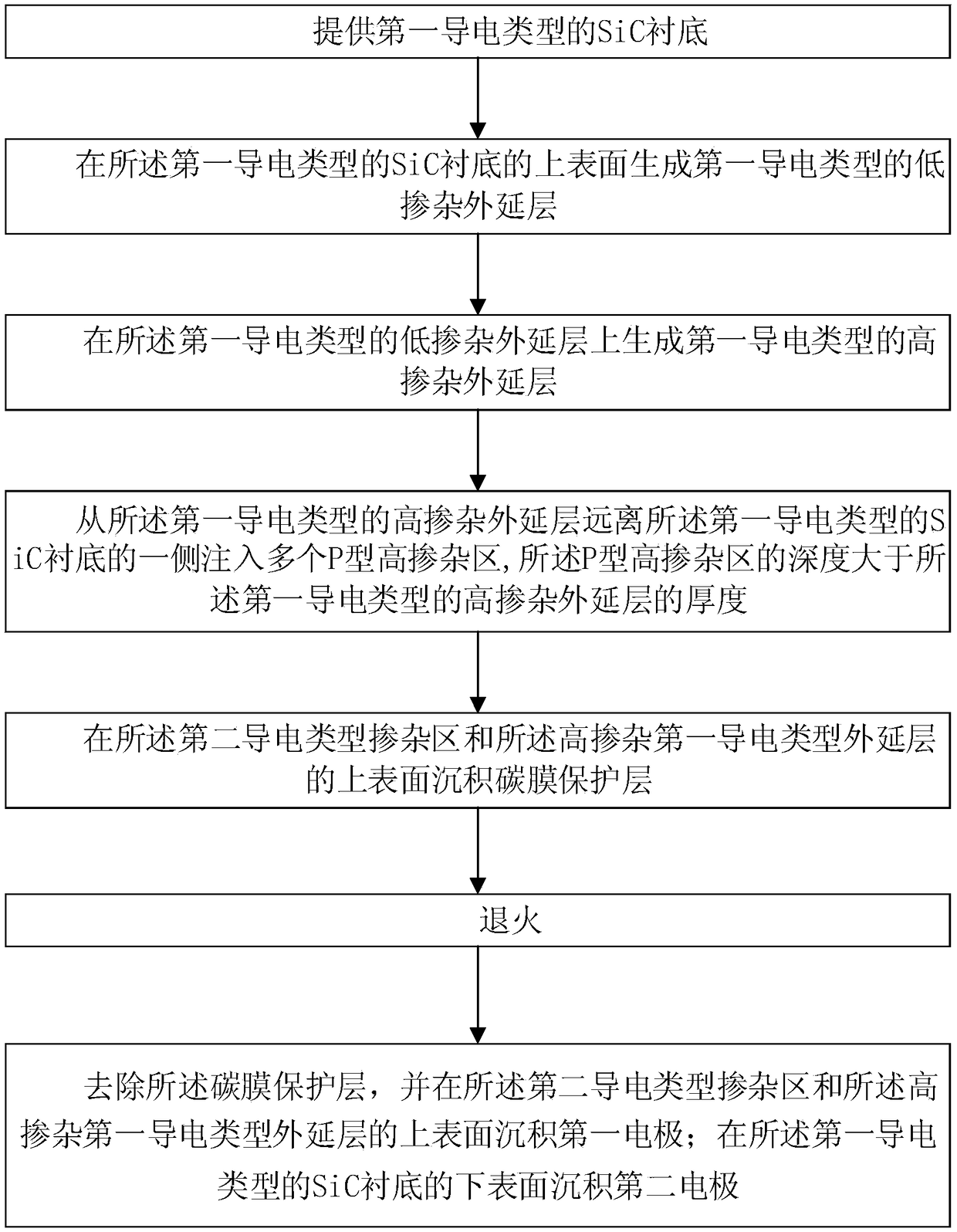

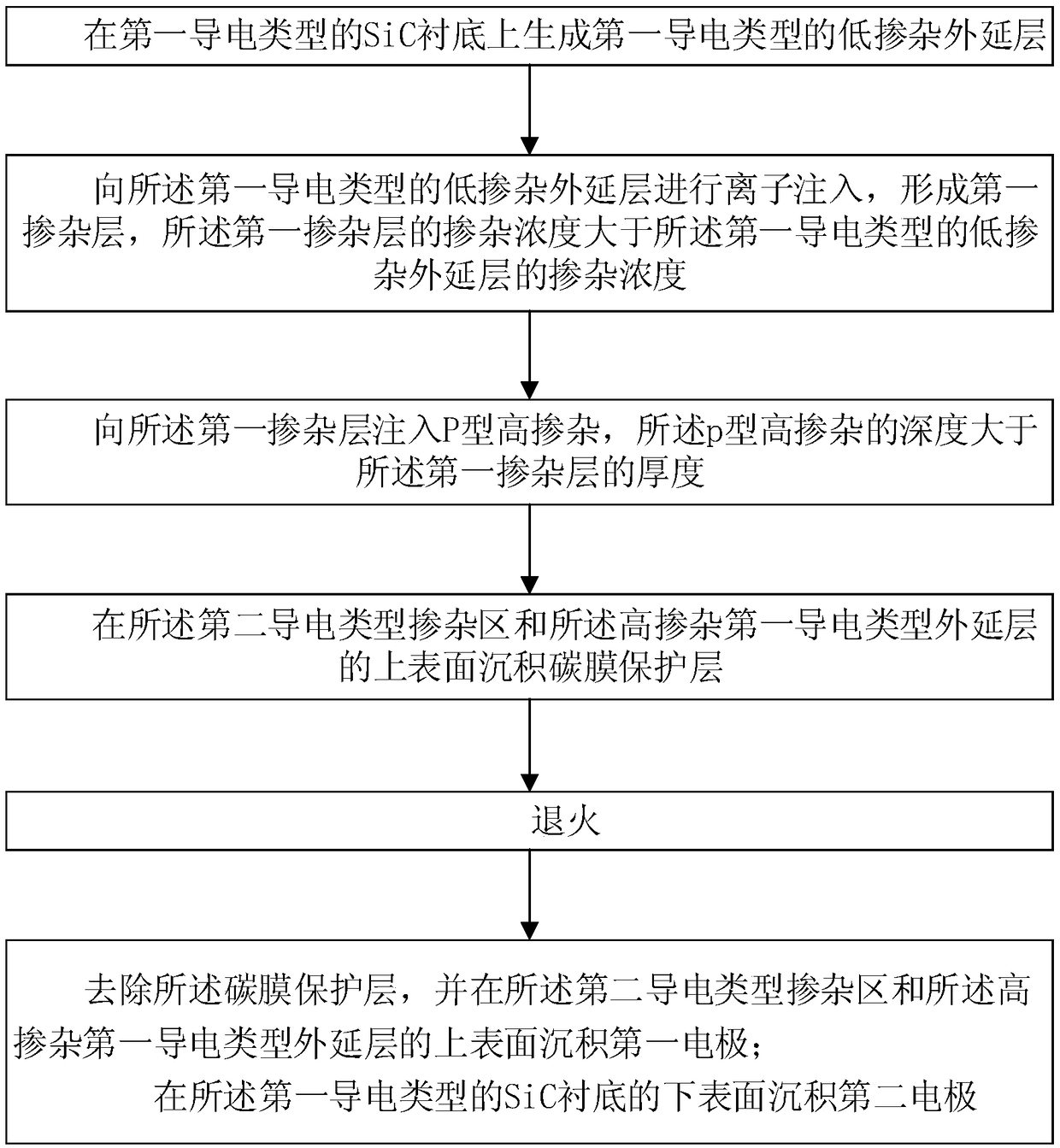

[0047] See attached picture, figure 1 Schematic diagram of the structure of the SiC junction barrier Schottky diode provided by the present invention; figure 2 A flow chart of the manufacturing method of the SiC junction barrier Schottky diode provided by the present invention; image 3 A flow chart of another manufacturing method of the SiC junction barrier Schottky diode provided by the present invention.

[0048] Usually a Schottky barrier is formed on a given semiconductor (such as n-type or p-type SiC), and there are only a limited number of barrier heights to choose from. Affected by the barrier height, the turn-on voltage of silicon carbide diodes is relatively large , in order to solve this technical problem, the present invention proposes an idea of introducing a thin layer that can control the amount of impurities on the semiconductor surface, so that the effective barrier height of the metal-semiconductor contact can be changed, thereby reducing the conductivity...

Embodiment 2

[0055] On the basis of the above embodiments, this embodiment further details the internal structure of the SiC junction barrier Schottky diode:

[0056] Take the first conductivity type as P type and the second conductivity type as N type as an example:

[0057] The P-type SiC substrate layer includes a first surface and a second surface, the first surface is provided with a low-doped P-type epitaxial layer, and the doping concentration of the low-doped P-type epitaxial layer is 10 15 atom / cm 3 order of magnitude, the doping concentration of the low-doped P-type epitaxial layer is less than the doping concentration of the P-type SiC substrate layer; further, a highly-doped P-type epitaxial layer is set on the upper surface of the low-doped P-type The doping concentration of the hetero P-type epitaxial layer is 10 16 atom / cm 3 order, the highly doped P-type epitaxial layer is provided with multiple N-type doped regions, and the implantation concentration is 10 18 atom / cm ...

Embodiment 3

[0060] On the basis of the above embodiments, an embodiment of the present invention provides a method for manufacturing a SiC junction barrier Schottky diode, specifically:

[0061] Step 1: providing a SiC substrate of the first conductivity type;

[0062] Step 2: forming a low-doped epitaxial layer of the first conductivity type on the upper surface of the SiC substrate of the first conductivity type;

[0063] Step 3: generating a highly doped epitaxial layer of the first conductivity type on the lowly doped epitaxial layer of the first conductivity type;

[0064] Step 4: Implanting a plurality of P-type highly doped regions from the side of the highly doped epitaxial layer of the first conductivity type away from the SiC substrate of the first conductivity type, and the depth of the P-type highly doped regions is greater than the thickness of the highly doped epitaxial layer of the first conductivity type;

[0065] Step 5: Depositing a carbon film protective layer on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com