Preparation method of coated polyetherimide membrane and application of coating polyetherimide membrane to lithium sulfur battery

A technology of polyetherimide and lithium-sulfur batteries, which is applied to battery components, circuits, electrical components, etc., can solve the problems of positive electrode active material loss, battery coulombic efficiency and cycle life reduction, and achieve electrochemical stability Effects of lifting, improved mechanical properties and thermal stability, and improved capacity retention and Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

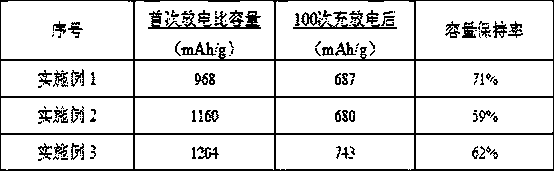

Embodiment 1

[0030] Dissolve 12.5g of PEI and 1.5g of polyvinylpyrrolidone in 36g of NMP, then place the obtained mixed casting solution in an oil bath, heat it at 75°C for 24h, then ultrasonically for 10min, and place it at 70°C Stand in the oven for defoaming for 12 hours to obtain a homogeneously cast mixed film solution; cast the obtained homogeneously mixed film cast solution on a glass plate, and then adjust the scraper parameters to obtain diaphragms with different film thicknesses; use a scraper to obtain different film thicknesses. The thick diaphragm is immersed in deionized water to separate phases to form pores, and then stand still, and the deionized water is constantly replaced during the period; after standing, the diaphragm is heated and dried in a vacuum drying oven, the heating and drying temperature is 60 ° C, and the drying time is 12 hours , to obtain a polyetherimide-based film, then molybdenum disulfide nanosheets, conductive carbon black and polyvinylidene fluoride t...

Embodiment 2

[0032]Dissolve 12.5g of PEI and 1.3g of carboxymethyl cellulose in 36.2g of NMP, then place the obtained mixed casting solution in an oil bath and heat it for 24h while stirring at 75°C, then sonicate for 10min, and place it at 70°C Stand in the oven for defoaming for 12 hours to obtain a homogeneously cast mixed film solution; cast the obtained homogeneously mixed film cast solution on a glass plate, and then adjust the scraper parameters to obtain diaphragms with different film thicknesses; use a scraper to obtain different film thicknesses. The thick diaphragm is immersed in deionized water to separate phases to form pores, and then stand still, and the deionized water is constantly replaced during the period; after standing, the diaphragm is heated and dried in a vacuum drying oven, the heating and drying temperature is 60 ° C, and the drying time is 12 hours , to obtain a polyetherimide-based film, then vanadium dioxide nanosheets, graphene and polyvinylidene fluoride are ...

Embodiment 3

[0034] Dissolve 12.5g of PEI and 1.4g of polyvinyl alcohol in 36.1g of NMP, then place the obtained mixed casting solution in an oil bath, heat it for 24h while stirring at 75°C, then sonicate it for 10min, and put it in an oven at 70°C Standing in the middle for degassing for 12 hours, the mixed film solution of homogeneous casting is obtained; the obtained homogeneous mixed casting solution is cast on a glass plate, and then the parameters of the scraper are adjusted to obtain diaphragms with different film thicknesses; diaphragms of different thicknesses are obtained with a scraper The diaphragm was immersed in deionized water for phase separation and pore formation, and then stood still, during which the deionized water was constantly replaced; after standing still, the diaphragm was heated and dried in a vacuum drying oven at a temperature of 60°C and a drying time of 12 hours. Polyetherimide-based film, and then tin dioxide nanosheets, carbon nanotubes and polyvinylidene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com