Portulaca oleracea flavone enzyme extraction technology adopting optimized response surface method

A purslane flavonoid enzymatic method and response surface method technology, which is applied in the field of food science and engineering, can solve problems such as rare reports, and achieve the effect of simple extraction process and mild extraction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1, the preparation method of purslane enzymatic hydrolyzate

[0039] Fresh purslane→selection→cleaning→finishing→pressing→enzymolysis→filtering→enzymolysis solution,

[0040] The specific process is:

[0041] (1) Raw material pretreatment: select fresh purslane that is free from rot, pests and damage, and cleaned with tap water, rinsed with pure water, and drained for later use.

[0042] (2) Finishing: Steam finishing for 5 minutes.

[0043] (3) Squeeze: Squeeze with a screw juicer to prevent or reduce air mixing and oxidation of raw materials during the pressing process.

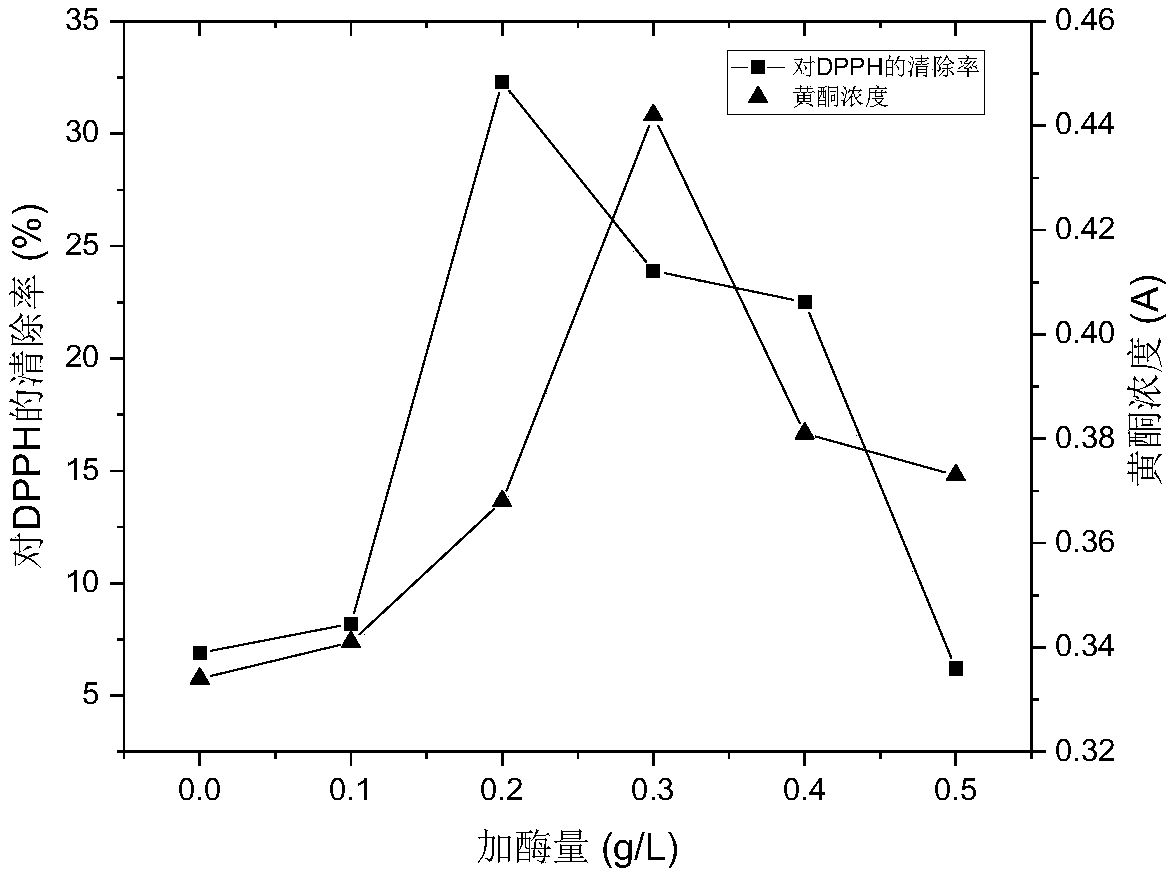

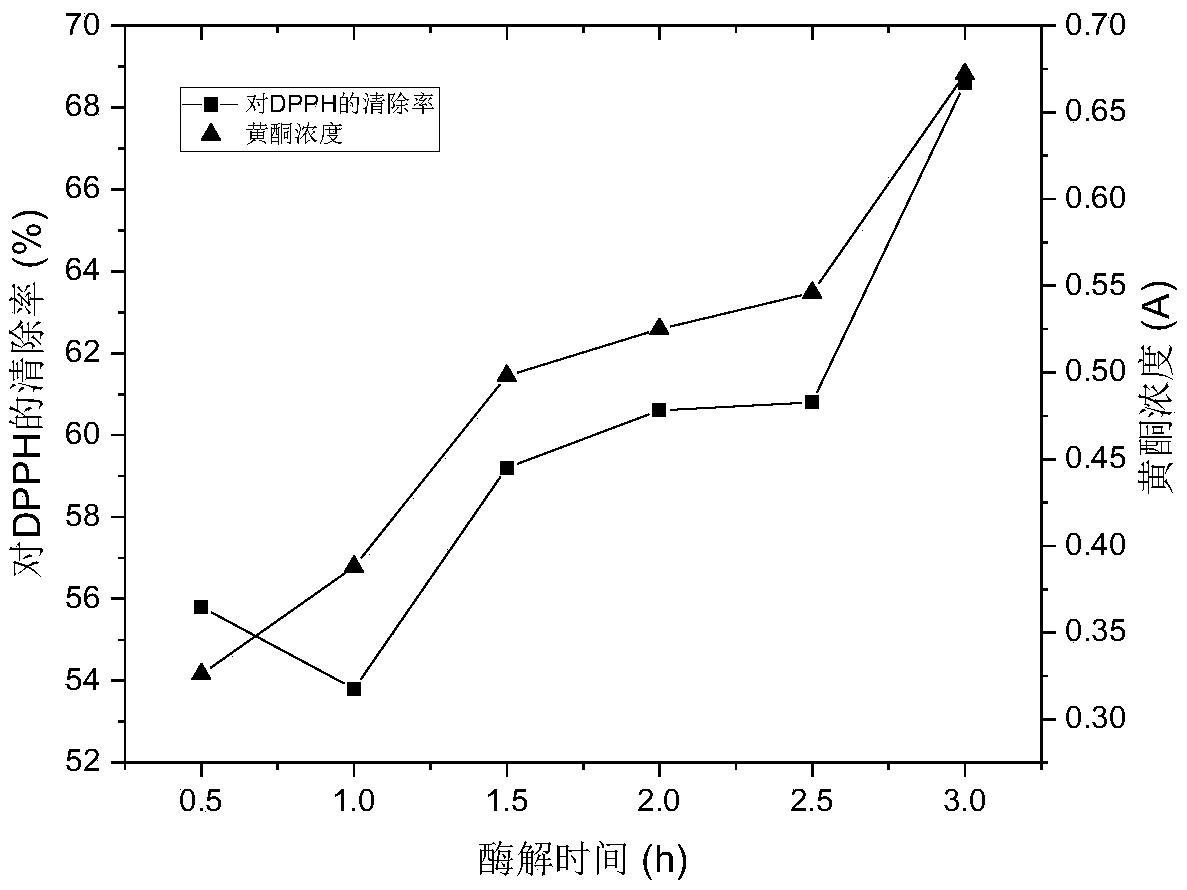

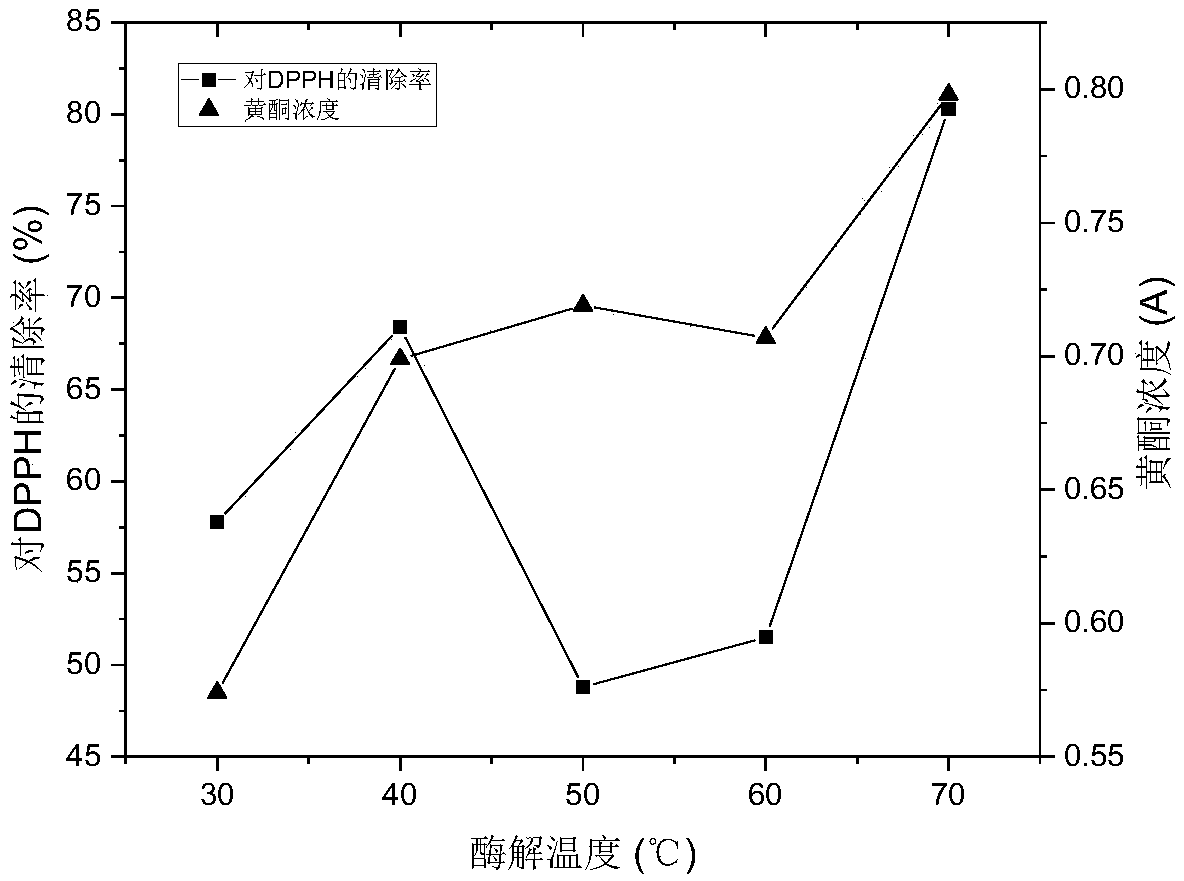

[0044] (4) Enzymolysis: Stir the crushed pulp evenly, carry out enzymolysis extraction with ultrapure water according to a certain slurry ratio at different temperatures, enzymolysis time, and the amount of pectinase added, and pass the single factor test and response surface method Determine the best ratio.

[0045] (5) Filtration: filter the enzymatic solution with four layers of gauze, heat th...

Embodiment 2

[0096] An enzymatic extraction process of purslane flavonoids, the process is fresh purslane→selection→cleaning→finishing→pressing→enzymolysis→filtering→enzymolysis solution, the specific process is as follows:

[0097] (1) Raw material pretreatment: select fresh purslane that is free from rot, pests and damage, and cleaned with tap water, rinsed with pure water, and drained for later use.

[0098] (2) Finishing: Steam finishing for 5 minutes.

[0099] (3) Squeeze: Squeeze with a screw juicer to obtain pulp, and pay attention to preventing or reducing the air in the process of pressing to oxidize the raw material.

[0100] (4) Enzymolysis: Stir the squeezed pulp evenly, add ultrapure water to make the ratio of pulp to water 1:20, add pectinase under the conditions of enzymolysis temperature 48°C and pH 5.5 for enzymolysis extraction, enzymolysis The time is 3.5h, and the dosage of pectinase is 0.25g / kg.

[0101] (5) Filtration: filter the enzymolysis solution with four layer...

Embodiment 3

[0104] An enzymatic extraction process of purslane flavonoids, the process is fresh purslane→selection→cleaning→finishing→pressing→enzymolysis→filtering→enzymolysis solution, the specific process is as follows:

[0105] (1) Raw material pretreatment: select fresh purslane that is free from rot, pests and damage, and cleaned with tap water, rinsed with pure water, and drained for later use.

[0106] (2) Finishing: Steam finishing for 5 minutes.

[0107] (3) Squeeze: Squeeze with a screw juicer to obtain pulp, and pay attention to preventing or reducing the air in the process of pressing to oxidize the raw material.

[0108] (4) Enzymolysis: Stir the squeezed pulp evenly, add ultrapure water to make the ratio of pulp to water 1:18, add pectinase under the conditions of enzymolysis temperature 55°C and pH 5.5 for enzymolysis extraction, enzymolysis The time is 3.2h, and the dosage of pectinase is 0.25g / kg.

[0109] (5) Filtration: filter the enzymolysis solution with four layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com