Calcium alginate-graphene oxide nanofiber and preparation method and drug-carrying calcium alginate-graphene oxide nanofiber

A calcium alginate and nanofiber technology, applied in the chemical characteristics of fibers, alginate man-made filaments, pharmaceutical formulations, etc., can solve the problems of strong hygroscopicity and low mechanical strength, achieve a good therapeutic effect, and reduce the release rate. , to avoid the effect of sudden release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

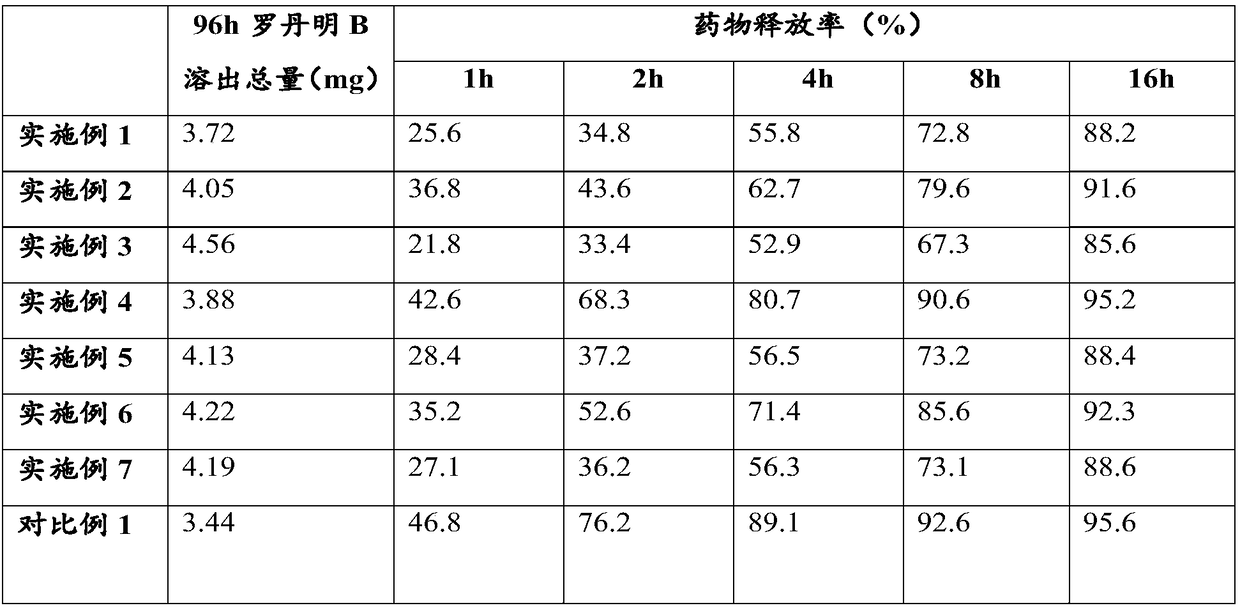

Examples

preparation example Construction

[0030] According to one aspect of the present invention, the present invention provides a method for preparing calcium alginate-graphene oxide nanofibers, comprising the following steps: passing a mixed solution of sodium alginate and graphene oxide and a calcium chloride solution through a microfluidic control Spinning to obtain calcium alginate-graphene oxide nanofibers.

[0031] The preparation method of the calcium alginate-graphene oxide nanofiber provided by the present invention is prepared by microfluidic spinning, the process is simple and convenient to operate, and the prepared calcium alginate-graphene oxide is obtained by adding graphene oxide into the raw material The nanofibers interact with the hydroxyl group in the calcium alginate molecule through the oxygen-containing groups on the graphene oxide sheet, which weakens the hydrogen bond between the calcium alginate and the water molecule, thereby reducing the swelling of the calcium alginate rate, to prevent th...

Embodiment 1

[0080] This embodiment provides drug-loaded calcium alginate-graphene oxide nanofibers, which are prepared according to the following steps:

[0081] (1) With distilled water as solvent, configure the mixed solution of rhodamine B, sodium alginate and graphene oxide, wherein, the mass concentration of sodium alginate is 2%, the mass concentration of graphene oxide is 0.1%, the mass concentration of rhodamine B The mass concentration is 1%;

[0082] (2) Using distilled water as a solvent, configure a calcium chloride solution, wherein the concentration of the calcium chloride solution is 1%;

[0083] (3) Using a dual-channel microfluidic chip to prepare drug-loaded calcium alginate-graphene oxide nanofibers, the mixed solution of rhodamine B, sodium alginate and graphene oxide is transported to the silk outlet channel through the first channel , the flow rate is 100mL / h; the calcium chloride solution is transported to the silk outlet channel through the second channel, and the...

Embodiment 2

[0085] This embodiment provides a drug-loaded calcium alginate-graphene oxide nanofiber. The difference between its preparation method and Example 1 is that in step (1), the mass concentration of sodium alginate is 6%. In step (2), the mass concentration of calcium chloride is 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com