Nanometer fiber air purifying material with chitosan powder on surface and preparation method of nanometer fiber air purifying material

An air purification material, chitosan nanotechnology, applied in the chemical characteristics of fibers, fiber processing, rayon manufacturing and other directions, can solve the problems of secondary pollution, biodegradability and poor human body affinity, and achieves a The effect of adsorption and filtering effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of the nanofiber air-purifying material containing chitosan powder on the surface, the specific steps are as follows:

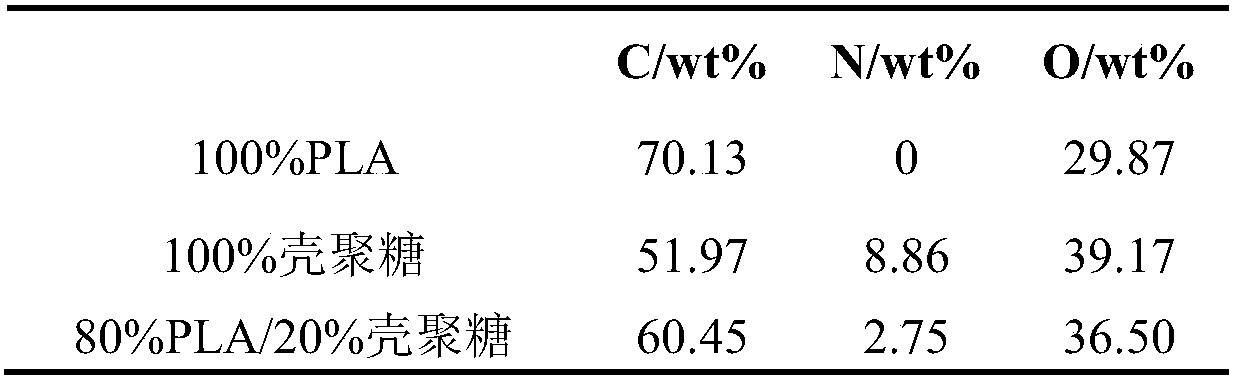

[0039] (1) dissolving PLA particles in a mixed solvent of DCM and DMAC with a mass ratio of 10:1 to obtain a PLA solution with a concentration of 8 wt %;

[0040] (2) adding the chitosan nano powder with a particle size of 100-600nm into the PLA solution and stirring until uniformly dispersed and ultrasonically oscillating for 90 minutes to obtain a spinning solution, wherein the content of the chitosan nano powder in the spinning solution is 3wt% ;

[0041] (3) The nanofiber air purification material containing chitosan powder on the surface is prepared by electrospinning with spunbonded non-woven fabric as the receiving substrate. The process parameters of electrospinning are: spinning temperature 17°C, spinning voltage 18kV, The spinning liquid flow rate is 1.5mL / h, and the receiving distance is 8cm; the receiving device of e...

Embodiment 2

[0047] The preparation method of the nanofiber air-purifying material containing chitosan powder on the surface, the specific steps are as follows:

[0048] (1) dissolving PLA particles in a mixed solvent of DCM and DMAC with a mass ratio of 10:1 to obtain a PLA solution with a concentration of 8 wt %;

[0049] (2) adding the chitosan nano powder with a particle size of 100-600nm into the PLA solution and stirring until uniformly dispersed and ultrasonically oscillating for 90 minutes to obtain a spinning solution, wherein the content of the chitosan nano powder in the spinning solution is 2wt% ;

[0050] (3) The nanofiber air purification material containing chitosan powder on the surface is prepared by electrospinning with spunbonded nonwoven fabric as the receiving substrate. The process parameters of electrospinning are: spinning temperature 20°C, spinning voltage 16kV, The flow rate of the spinning solution is 1mL / h, and the receiving distance is 12cm; the receiving devi...

Embodiment 3

[0057] The preparation method of the nanofiber air-purifying material containing chitosan powder on the surface, the specific steps are as follows:

[0058] (1) dissolving PLA particles in a mixed solvent of DCM and DMAC with a mass ratio of 10:1 to obtain a PLA solution with a concentration of 6 wt %;

[0059] (2) Add the chitosan nanopowder with a particle size of 100-600nm into the PLA solution and stir until uniformly dispersed and ultrasonically oscillate for 60 minutes to obtain a spinning solution, wherein the content of the chitosan nanopowder in the spinning solution is 1.5wt %;

[0060] (3) The nanofiber air purification material containing chitosan powder on the surface is prepared by electrospinning with hot-melt non-woven fabric as the receiving substrate. The process parameters of electrospinning are: spinning temperature 22°C, spinning voltage 18kV, The flow rate of spinning solution is 1.5mL / h, and the receiving distance is 10cm; the receiving device of electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com