Spatial coherent X-ray source of surface-transmitting array structure

An array structure and X-ray technology, which is applied in the field of X-ray interference imaging, can solve problems such as difficult application, affecting emission efficiency, and small X-ray divergence angle, so as to increase the range of emission angles, improve imaging quality, and improve utilization efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

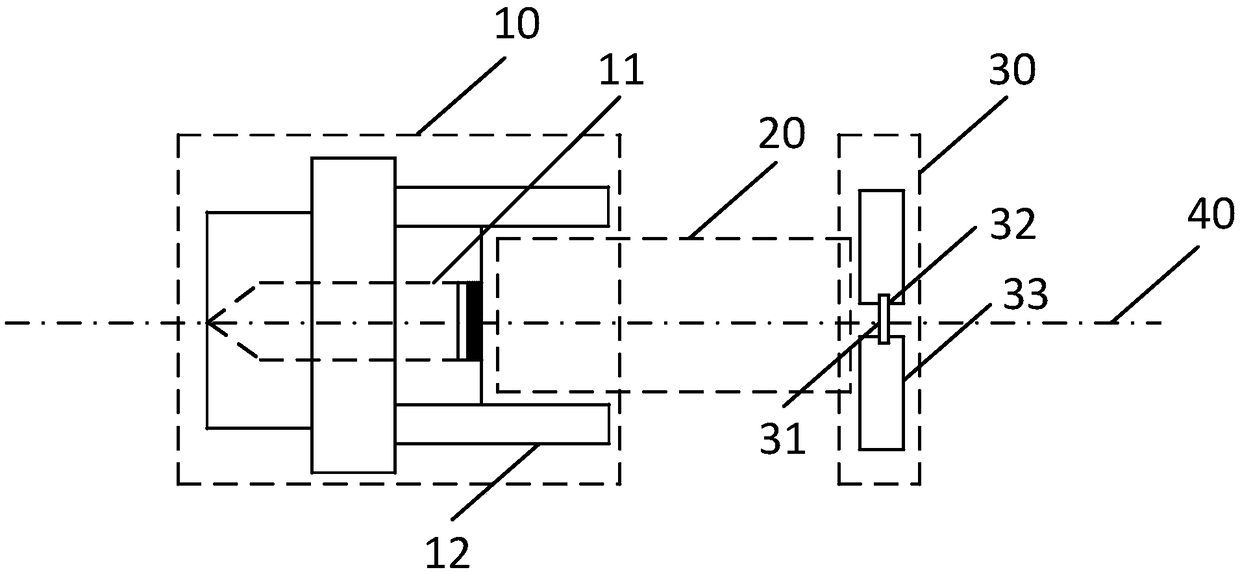

[0057] see figure 1 , is a structural schematic diagram of a spatially coherent X-ray source with a surface-emitting transmission array structure provided in this embodiment. The spatially coherent X-ray source includes a cathode 10, an electron beam converging device 20, and a transmission anode target 30. The cathode 10 includes A planar emission type electron emitter 11, wherein the planar emission type electron emitter 11, the electron beam converging device 20 and the transmissive anode target 30 are sequentially arranged on the same optical path and have a common optical axis 40;

[0058] The plane emission type electron emitter 11 has an emission plane perpendicular to the optical axis 40 for emitting the first electron beam;

[0059] The electron beam converging device 20 is used to receive and converge the first electron beam emitted by the emission plane to obtain a second electron beam, and emit the second electron beam to the transmission anode target 30 to bombard...

Embodiment 2

[0090] A schematic structural diagram of a spatially coherent X-ray source provided in this embodiment. Wherein, the spatially coherent X-ray source is optimized by the spatially coherent X-ray source described in Embodiment 1, wherein,

[0091] The electron beam converging device 20 included in the spatially coherent X-ray source is a non-imaging electron optical focusing device;

[0092] The non-imaging electron optical focusing device is used to focus the electron beam emitted by the plane-emitting electron emitter through the spontaneously generated high-voltage electric field;

[0093] The transmissive anode target is set on the focal plane of the non-imaging electron optical focusing device

[0094] As an optional embodiment, the transmissive anode target 30 includes a heat dissipation electrode 33 for heat dissipation, a microstructure target 31 for determining the X-ray focal spot structure and beam spot size, and a substrate 32 for carrying the microstructure target ...

Embodiment 3

[0113] A schematic structural diagram of a spatially coherent X-ray source provided in this embodiment. Wherein, the spatially coherent X-ray source is optimized by the spatially coherent X-ray source described in Embodiment 1, wherein,

[0114] The electron beam converging device 20 included in the spatially coherent X-ray source is an electron optical imaging device;

[0115] The electron optical imaging device is used to focus the electron beam emitted by the plane-emitting electron emitter 11 so that the electron beam is focused to generate an image, and the shape of the image is the same as the internal structure of the plane-emitting electron emitter 11;

[0116] The transmissive anode target 30 is disposed on the image plane of the electron optical imaging device.

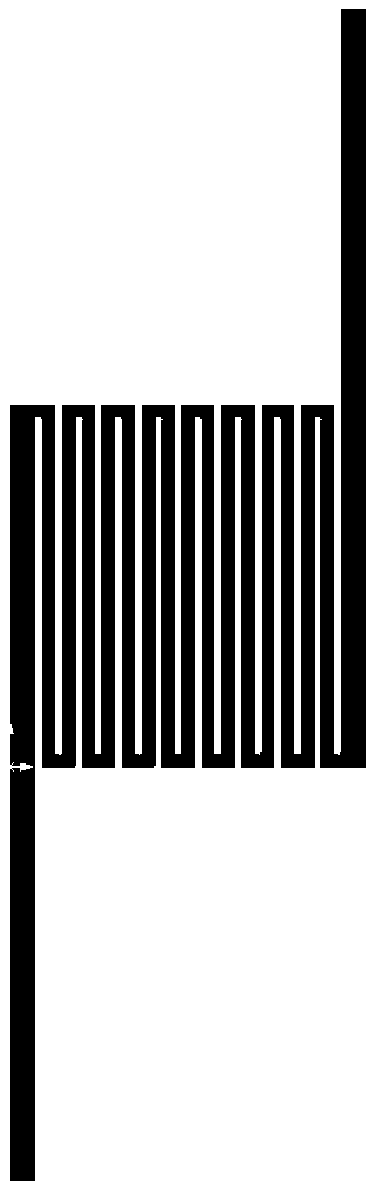

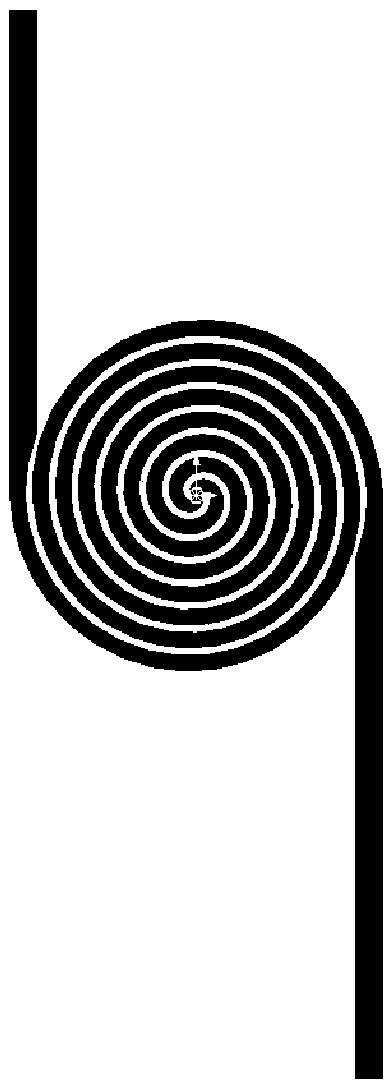

[0117] As an optional embodiment, the planar emission type electron emitter 11 has a two-dimensional dot array microstructure, an annular zone microstructure or a one-dimensional line array microstructure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com