Membrane type oxygenator with biocompatible coating

A technology of membrane oxygenator and biocompatibility, which is applied in the field of biomedical engineering, can solve the problems of reducing the blood prefill volume of the oxygenator, and achieve improved biocompatibility, high efficiency, and small blood prefill volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1 A membrane oxygenator with biocompatible coating

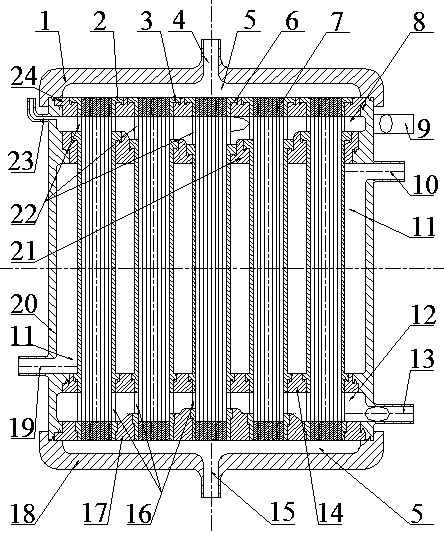

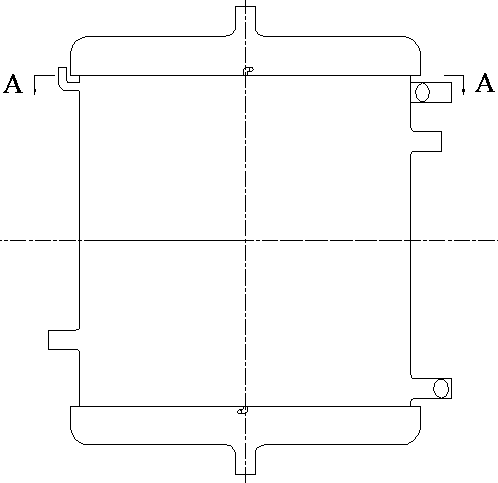

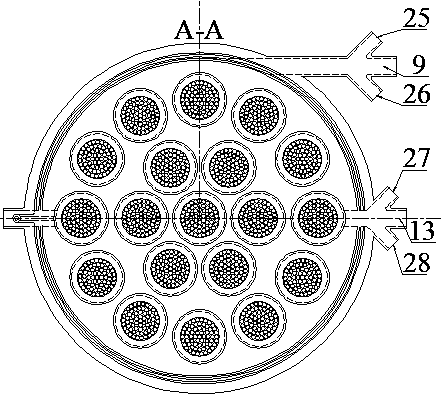

[0051] 1. Such as figure 1 , 2 As shown in Figure 3, a membrane oxygenator with a biocompatible coating is cylindrical as a whole, including a hollow fiber membrane oxygenation unit 7 and a heat exchange unit. There are several equal intervals in the oxygenator. Each oxygenation unit 7 is surrounded by the heat exchange unit; in addition, the oxygenator further includes a biocompatible coating coated on the surface of the hollow fiber membrane. The two processes of heat exchange and gas exchange can be realized simultaneously when blood is flowing. During the oxygenation process, since the heat exchange unit surrounds the oxygenation unit, the blood in the oxygenation unit loses less heat, the temperature gradient during blood flow is small, the heat preservation effect is better, the oxygen and blood flow in opposite directions, and the oxygenation efficiency is high.

[0052] The thickness of the biocompatible c...

Embodiment 2

[0076] Example 2 A hollow fiber membrane oxygenator with small precharge

[0077] 1. In order to further improve the comprehensive use effect of the oxygenator and reduce the precharge, the hollow fiber membrane oxygenator of this embodiment has the following improvements on the basis of embodiment 1:

[0078] Such as figure 1 , 2 , 3, a small pre-charged hollow fiber membrane oxygenator, from top to bottom are the upper end cover 1, the upper fixing plate 24, the middle and upper fixing plate 21, the middle and lower fixing plate 14, the lower fixing plate 17 and the lower end cover 18, the outside of each layer of the fixed plate is connected and sealed with the oxygenator housing 20 through a stepped flange, and the inside is connected to the inner, middle, and outer metal pipes with circumferential openings at both ends through a stepped flange. seal.

[0079] First use resin to bond the oxygenator housing 20, the upper fixing plate 24, and the upper middle fixing plate 21 throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com