Adsorbent and preparation method thereof

A technology of adsorbent and physical adsorbent, which is applied in the preparation of adsorbent and the field of adsorbent for small molecule gas adsorption, can solve the problems of poor economy and compatibility, and poor treatment effect of small molecule organic matter, so as to improve the treatment effect, Suitable for large-scale industrial promotion and application, good technical compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

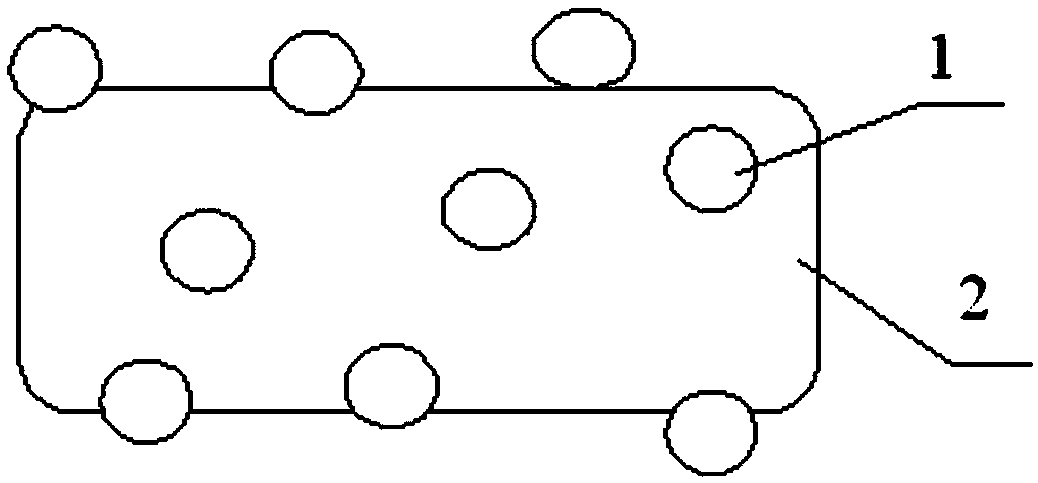

[0032] an adsorbent such as figure 1 As shown, NaY molecular sieve and calcium chloride comprising a silicon-aluminum ratio (molar ratio) of 6:1, the NaY molecular sieve is a physical adsorbent 2, and the calcium chloride is a chemical adsorbent 1, and calcium chloride is attached to NaY On the molecular sieve, that is, the chemical adsorbent 1 is attached to the physical adsorbent 2, which may be attached to the inner surface and / or the outer surface of the physical adsorbent 2.

[0033] The weight ratio of the NaY molecular sieve is about 85%, and the weight ratio of calcium chloride is about 15%.

[0034] This embodiment also provides a preparation method for the above-mentioned adsorbent, comprising the following steps:

[0035] (1) placing the NaY molecular sieve having a particle diameter between about 100nm-10 μm in a calcium chloride solution and stirring to obtain a mixture after filtering, wherein the weight of calcium chloride accounts for 15% of the total weight o...

Embodiment 2

[0041] An adsorbent comprises NaY molecular sieve with a silicon-aluminum ratio (molar ratio) of 6:1 and calcium chloride, and the calcium chloride is attached to the NaY molecular sieve.

[0042] The weight ratio of the NaY molecular sieve is about 80%, and the weight ratio of calcium chloride is about 20%.

[0043] This embodiment also provides a preparation method for the above-mentioned adsorbent, comprising the following steps:

[0044] (1) placing the NaY molecular sieve with a particle diameter between about 100nm-10 μm in a calcium chloride solution and stirring to obtain a mixture after filtering, wherein the weight of calcium chloride accounts for 20% of the total weight of the mixture;

[0045] (2) adding a small amount of silica sol binder in the mixture, forming spherical particles with a diameter of about 4mm by granulation;

[0046] (3) performing infrared drying on the spherical particles at 105°C;

[0047] (4) After the dried spherical particles are removed ...

Embodiment 3

[0050] An adsorbent comprising silica gel and magnesium chloride attached to the silica gel.

[0051] The weight ratio of the silica gel is about 70%, and the weight ratio of the magnesium chloride is about 30%.

[0052] This embodiment also provides a preparation method for the above-mentioned adsorbent, comprising the following steps:

[0053] (1) mixing silica gel particles with a particle diameter between about 100nm-10 μm and magnesium chloride particles, wherein the weight of magnesium chloride accounts for 20% of the total weight of the mixture;

[0054] (2) extruding the mixture;

[0055](3) hot air drying the molding at 150°C;

[0056] (4) After the dried molded product is removed at about 400° C. to obtain a composite adsorbent.

[0057] Use the above-mentioned adsorbent as the filling layer, with a height of 15cm, and a blowing concentration of 200mg / m at a wind speed of 2m / s 3 Ethanol, temperature 25°C, humidity 60%RH, the concentration of ethanol at the outlet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com