Application of porous MgO catalyst in synthesis of vinylethylene carbonate

A technology of ethylene ethylene carbonate and catalyst, which is applied in the application field of porous MgO catalyst in synthesizing ethylene ethylene carbonate, can solve the problems of difficult separation and recovery of catalyst, large amount of catalyst used, low product yield, etc. Remarkable performance, short response time and reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

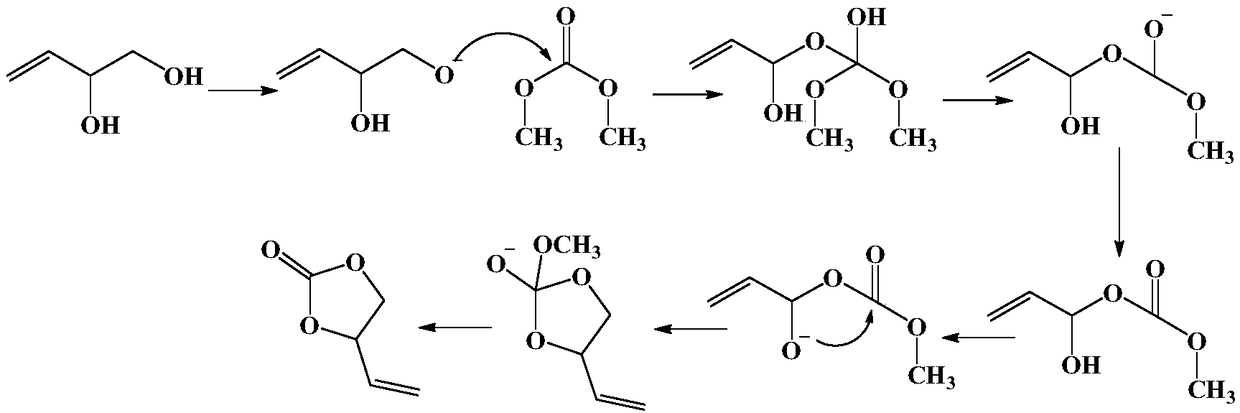

Method used

Image

Examples

preparation example Construction

[0024] The porous MgO catalyst was prepared as follows:

[0025] (1) In a beaker, add 1 g of polyethylene oxide-polypropylene oxide-polyethylene oxide (chemical formula is (C 2 H 4 O) 106 (C 3 H 6 O) 70 (C 2 H 4 O) 106 ) was dissolved in absolute ethanol, followed by adding 3g Mg(NO 3 ) 2 ·6H 2 O and 3g of phenolic resin, stirred for 2h to make them fully contact, then coated on glass, transferred to a 30°C thermostat for 12h, scraped off the film, transferred to a tube furnace, N 2 Bake at 600 °C for 6 h under the atmosphere, bring it to room temperature, and then switch the gas to O 2 , and heated to 350 °C for 2 h to obtain porous MgO-1.

[0026] (2) 1 g polyethylene oxide-polypropylene oxide-polyethylene oxide (chemical formula is (C 2 H 4 O) 106 (C 3 H 6 O) 70 (C 2 H 4 O) 106 ) was dissolved in absolute ethanol, followed by adding 5g Mg(NO 3 ) 2 ·6H 2 O and 7g of phenolic resin, stirred for 2h to make them fully contact, then coated on glass, trans...

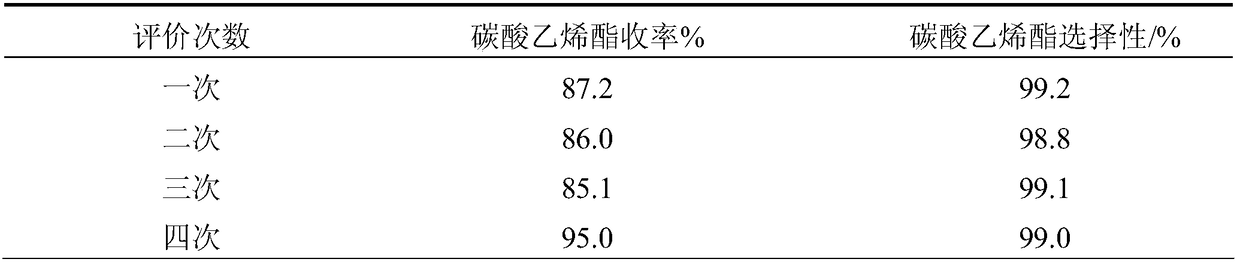

Embodiment 1

[0031] 10mL of dimethyl carbonate, 10mL of 1-butene-3,4-diol and 1.04g of MgO-1 were successively added to the flask, put the flask into an oil bath, heated with magnetic stirring, and heated to 100°C, at this temperature The reaction was carried out for 4 hours. After cooling to room temperature, the reaction solution was centrifuged and analyzed. The selectivity of ethylene ethylene carbonate was 99.1%, and the yield was 64.1%.

Embodiment 2

[0033] 19mL of dimethyl carbonate, 10mL of 1-butene-3,4-diol and 0.1g of MgO-1 were successively added to the flask, the flask was placed in an oil bath, heated with magnetic stirring, heated to 140°C, at this temperature The reaction was carried out for 8 hours. After cooling to room temperature, the reaction solution was centrifuged and analyzed. The selectivity of ethylene ethylene carbonate was 98.7% and the yield was 24.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com