A perfluorinated ionic resin

A technology of perfluorinated ions and resins, which is applied in the field of ion polymers, can solve the problems of thermal stability and corrosion resistance decline, ion exchange capacity reduction, and influence on electrical conductivity, etc., and achieve good thermal stability and corrosion resistance. The effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

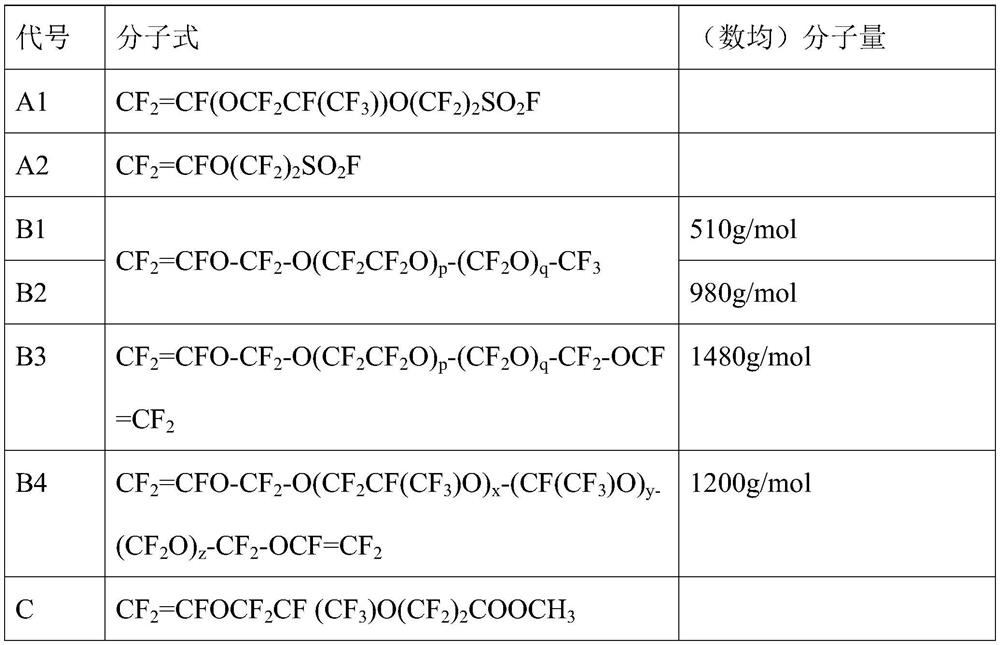

Method used

Image

Examples

Embodiment 1

[0042] Replace the 5L stainless steel reactor equipped with stirring, temperature control components, explosion-proof components, and nitrogen pipelines with high-purity nitrogen, and use vacuum as the polymerization medium 2500g of perfluorocyclic ether, 350g of sulfonyl fluoride monomer A1, and all 30g of fluoropolyether monomer B2 and 4g of initiator benzoyl peroxide were pumped into the reactor, and then 135g of tetrafluoroethylene was introduced, and the temperature was raised to 75°C with stirring, and then the reactor was kept at 1.2-1.5MPa. Continue to feed 285g of tetrafluoroethylene, keep warm and react until the pressure in the kettle no longer decreases, then cool down to stop the reaction. After the pressure is released, the material is discharged, the material is transferred to a distillation device, and the volatile components are evaporated to obtain a powder product, which is then washed with ethanol three times and dried to obtain the perfluoroionic resin of t...

Embodiment 2

[0045] Except that the perfluoropolyether monomer was replaced by B1, the others were the same as in Example 1.

[0046] DTA test resin decomposition temperature (T d ) is 371°C; the exchange capacity IEC of the resin measured by acid-base titration is 1.27mmol / g; after the above resin is made into an ionic membrane with a film thickness of 120 microns, the membrane is measured according to the method in the national standard GB / T 16579.2 The tear resistance is 43N.

Embodiment 3

[0048] Except that the perfluoropolyether monomer is replaced by B3, the others are the same as in Example 1.

[0049] DTA test resin decomposition temperature (T d ) is 372°C; the exchange capacity IEC of the resin measured by acid-base titration is 1.21mmol / g; after the above resin is made into an ionic membrane with a film thickness of 120 microns, the membrane is measured according to the method in the national standard GB / T 16579.2 The tear resistance is 46N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com