Preparation method for high activity high molecular weight low unsaturated polyether polyol

A polyether polyol and high molecular weight technology is applied in the field of preparation of high-activity, high-molecular-weight and low-unsaturation polyether polyols, and can solve the problems of performance, unsaturation and stability effects, and complicated catalyst removal technology. , to reduce the content of volatile organic compounds, reduce product odor and improve reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

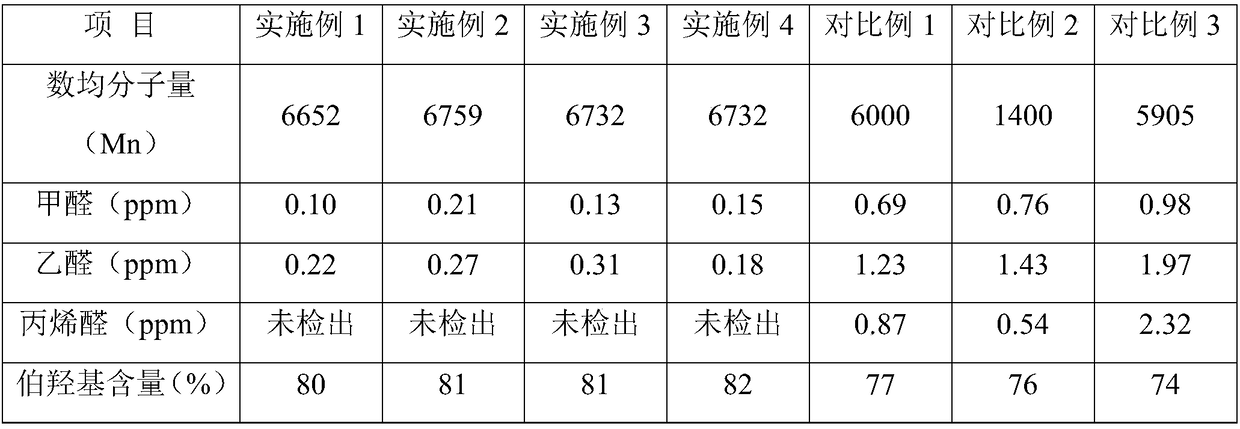

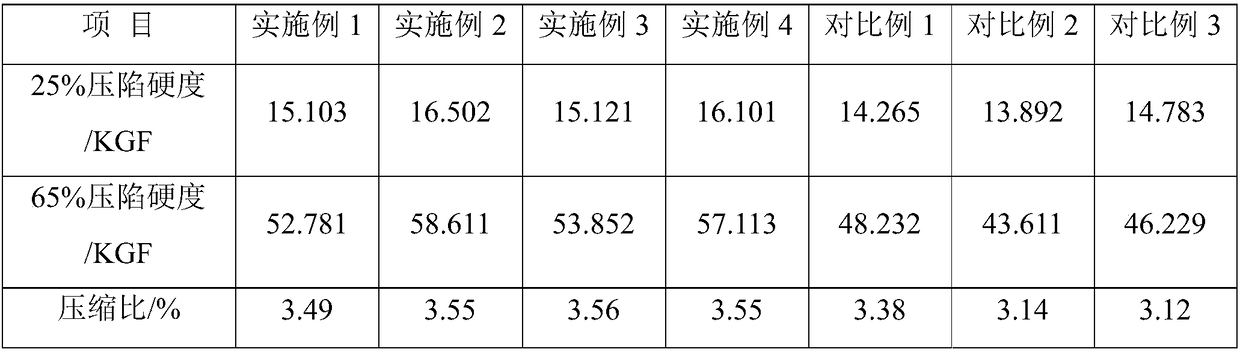

Examples

Embodiment 1

[0029] (1) Preparation of polyether polyol oligomers

[0030] at 15m 3 Add 576kg glyceryl ether (400 molecular weight), 28.8kg propylene glycol and 4kg tetrakis (tetramethylguanidinium) phosphazene chloride in the stainless steel reaction kettle, carry out nitrogen replacement, measure the oxygen content in the reaction kettle to be lower than 80ppm. The temperature was raised to 100°C, and dehydration was carried out by nitrogen bubbling under reduced pressure. Keep the temperature in the kettle at 102±2°C and the pressure at -0.1~0.3MPa, continuously add 7461kg of propylene oxide, react under internal pressure for 60 minutes, the reaction temperature is 102±2°C, and then remove the monomer for 30 minutes to obtain Polyether polyol oligomer with high catalytic activity.

[0031] (2) Preparation of high activity and high molecular weight polyether polyol crude polymer

[0032] Use the above-mentioned polyether polyol oligomer with high catalytic activity as the basic polyet...

Embodiment 2

[0037] (1) Preparation of polyether polyol oligomers

[0038] at 15m 3 Add 752kg glycerol ether (600 molecular weight), 15kg glycerol and 66kg tetrakis (tetramethylguanidinium) phosphazene hydroxide in the stainless steel reaction kettle, carry out nitrogen replacement, measure the oxygen content in the reaction kettle to be lower than 80ppm. The temperature was raised to 100°C, and dehydration was carried out by nitrogen bubbling under reduced pressure. Keep the temperature in the kettle at 138±2°C, the pressure at -0.1~0.3MPa, continuously add 5828kg of propylene oxide, react under internal pressure for 60 minutes, the reaction temperature is 138±2°C, and then remove the monomer for 30 minutes to obtain Polyether polyol oligomer with high catalytic activity.

[0039] (2) Preparation of high activity and high molecular weight polyether polyol crude polymer

[0040] Use the above-mentioned polyether polyol oligomer with high catalytic activity as the basic polyether, keep t...

Embodiment 3

[0045] (1) Preparation of polyether polyol oligomers

[0046] at 15m 3 Add 479kg glycerol ether (550 molecular weight), 4.79kg sorbitol and 28kg tetrakis (tetramethylguanidinium) phosphazene bicarbonate in the stainless steel reaction kettle, carry out nitrogen replacement, measure the oxygen content in the reaction kettle to be lower than 80ppm. The temperature was raised to 100°C, and dehydration was carried out by nitrogen bubbling under reduced pressure. Keep the temperature in the kettle at 110±2°C, the pressure at -0.1~0.3MPa, continuously add 4249kg of propylene oxide, react under internal pressure for 60 minutes, the reaction temperature is 110±2°C, and then remove the monomer for 30 minutes to obtain Polyether polyol oligomer with high catalytic activity.

[0047] (2) Preparation of high activity and high molecular weight polyether polyol crude polymer

[0048] Use the above-mentioned polyether polyol oligomer with high catalytic activity as the basic polyether, ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com