Polyethylene multi-pore plum-shaped pipe and preparation method thereof

A plum-blossom tube and polyethylene technology, which is applied in the field of polyethylene porous plum-blossom tubes and their preparation, can solve the problems of uneven flame retardant performance of plum blossom tube walls, easy agglomeration of flame retardants and the like, and achieve uniform and stable distribution and high flame retardant ability. , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The specific preparation process of composite flame-retardant polyvinyl alcohol is as follows:

[0026] Step 1: Add 1kg of red phosphorus into 10L of water, add 1.2kg of sodium hydroxide to it at the same time, mix well, add 20L of magnesium chloride aqueous solution with a mass fraction of 5% to it dropwise, stir while adding, and react after the addition is complete Filter after 30-50 minutes, then use ethanol and dry to obtain a composite flame retardant;

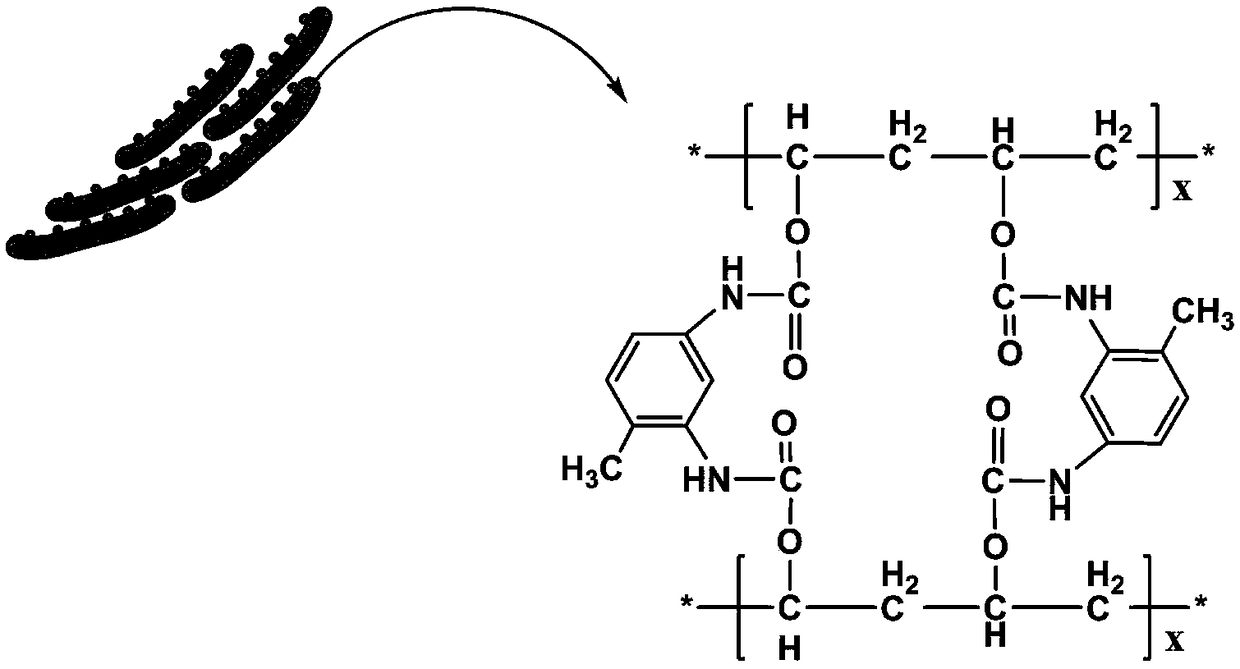

[0027] Step 2: Weigh 1 kg of low-molecular-weight polyvinyl alcohol and add it to 80°C water to dissolve it, and at the same time add 0.53 kg of the composite flame retardant prepared in step 1, then ultrasonically disperse at 80°C for 30 minutes, and then drop by drop under constant temperature conditions Add 1.05 kg of toluene diisocyanate dropwise to the reaction vessel, react for 2 hours after the addition is complete, cool down to room temperature, filter and wash to obtain composite flame-retardant polyvinyl...

Embodiment 2

[0029] The specific preparation process of composite flame-retardant polyvinyl alcohol is as follows:

[0030] Step 1: Add 1kg of red phosphorus into 10L of water, add 1.2kg of sodium hydroxide to it at the same time, mix well, add 20L of magnesium chloride aqueous solution with a mass fraction of 5% to it dropwise, stir while adding, and react after the addition is complete Filter after 30-50 minutes, then use ethanol and dry to obtain a composite flame retardant;

[0031] Step 2: Weigh 1kg of low-molecular-weight polyvinyl alcohol and add it to 80°C water to dissolve it, and at the same time add 0.58kg of the composite flame retardant prepared in step 1, then ultrasonically disperse at 80°C for 30min, and then drop by drop under constant temperature conditions Add 1.09 kg of toluene diisocyanate dropwise to the reaction container, react for 2 hours after the dropwise addition is complete, cool down to room temperature, filter and wash to obtain composite flame-retardant poly...

Embodiment 3

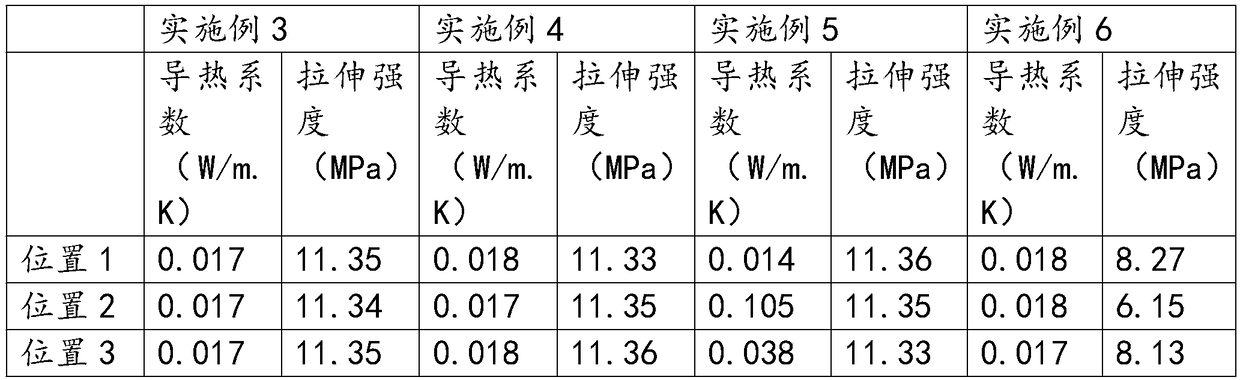

[0033] A preparation method of polyethylene porous plum blossom tube, the specific preparation process is as follows:

[0034] In the first step, add 6.5kg of low-density polyethylene and 5.5kg of ethylene-vinyl acetate copolymer into the twin-screw extruder, knead at 200°C for 3-5min, and then add 1.8kg of azobisisobutyronitrile , mixed at constant temperature for 1 hour, then added 2.4 kg of polyamide and 0.3 kg of functional additives, and heated to 230 ° C for 5-10 minutes; low density polyethylene and ethylene-vinyl acetate copolymer in azobisisobutyronitrile Polymerized under the action to form a macromolecular resin, which can improve the strength and toughness of the plum blossom tube; the functional additives include talcum powder, surfactants, antioxidants and wetting agents, of which talcum powder, surfactants, antioxidants and wetting agents The mass ratio of the aerosol is 12:2:3:8;

[0035] In the second step, when the temperature in the mixer in the first step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com