Composite cellulase system and its application in the production of starch fuel ethanol

A technology of compound cellulase and compound cellulose, which is applied in the direction of biofuels, enzymes, enzymes, etc., can solve the problems of the influence of yeast growth and fermentation, high viscosity of sugar solution, and high solid content, and achieve the reduction of total sugar and viscosity, The effect of ethanol yield increase and efficient conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

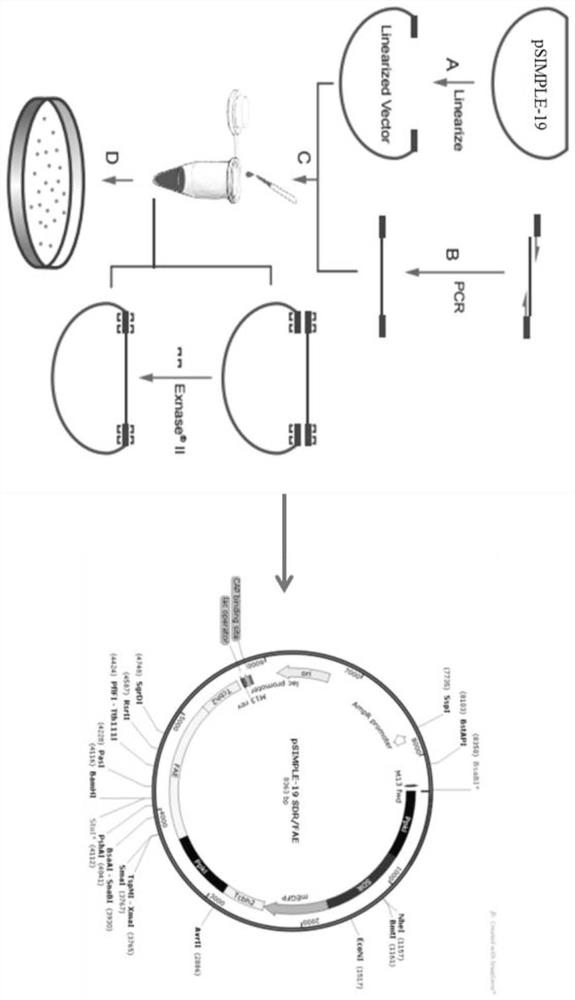

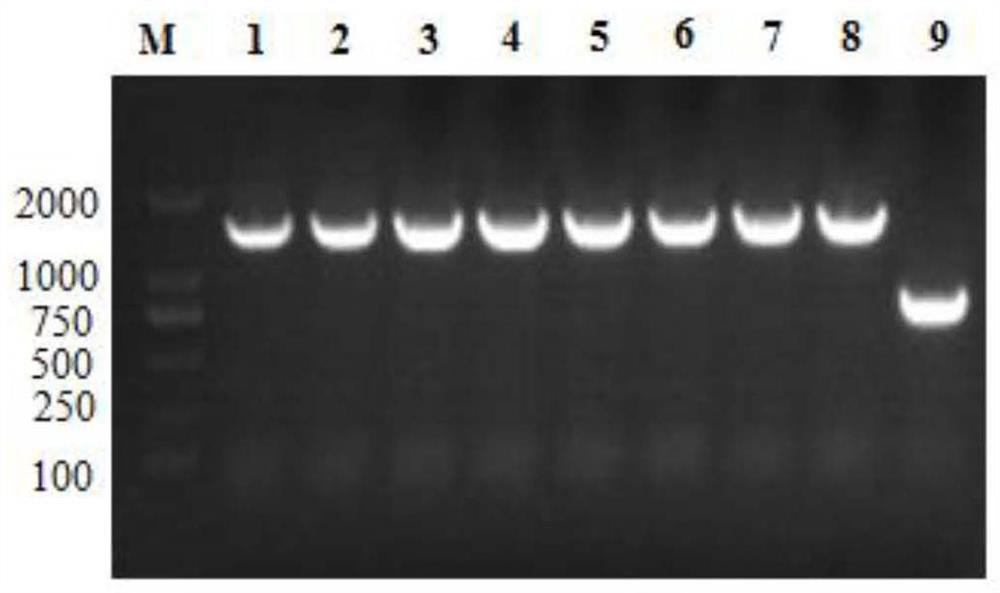

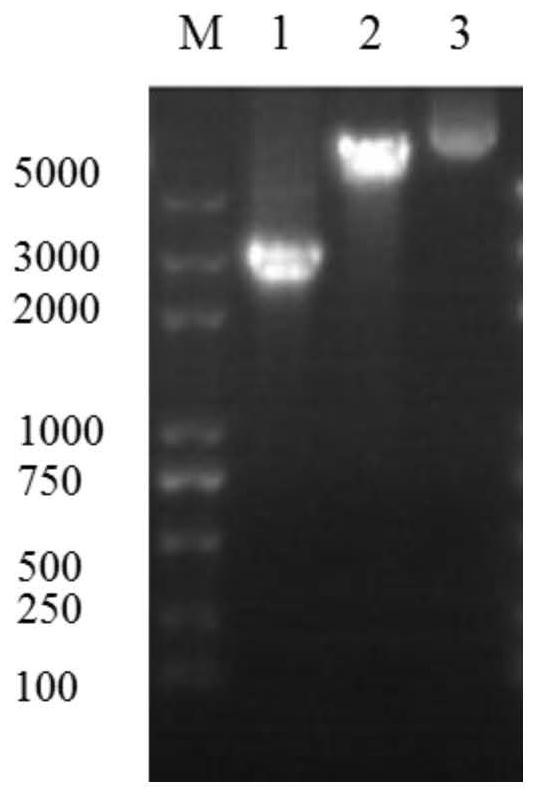

[0042] The present invention provides a complex cellulase line prepared by the following method, the method comprising the following steps:

[0043] The aspergillus niger converted to feruliformin gene of juniperoidyces source and the dehydrogenase gene of juniperpenoidyces derived from penicillium is inoculated in fermentation medium II. fermentation culture was obtained by fermentation culture I., the fermentation culture liquid I. is a feruliformase containing a juniperpene source and a dehydrogenase transforming enzyme line of juniperceous penicillis, and a β - glucosidase of aspergillus niger source;

[0044] Trichoderma reticulate is inoculated in 3% of the inoculation amount in fermentation medium I. fermentation culture to obtain fermentation culture medium II., the fermentation culture liquid II. is a cellulase containing Trichoderma reedi source; and

[0045] The fermentation culture solution I. was compounded (well mixed) according to the volume ratio 1:10 to obtain a c...

Embodiment 2

[0052] The present invention provides a complex cellulase line prepared by the following method, the method comprising the following steps:

[0053] The aspergillus niger is inoculated with 4% of the inoculation amount in the fermentation medium II. fermentation culture was obtained by fermentation culture I., the fermentation culture liquid I. is a ferulita containing a juniperpene source and a dehydrogenase of a juniperpenis source of aspergillus niger, and a β - glucosidase of aspergillus niger;

[0054] Trichoderma reticulate according to the amount of inoculation 4% in the fermentation medium I. fermentation culture to obtain fermentation culture ii., the fermentation culture liquid II. is a cellulase containing Trichoderma reedi derived from; and

[0055] The fermentation culture solution I. was compounded with the fermentation culture medium II. according to the volume ratio of 1:8.5 (well mixed) to obtain a complex cellulase line.

[0056] Wherein, the fermentation medium ...

Embodiment 3

[0062] The present invention provides a complex cellulase line prepared by the following method, the method comprising the following steps:

[0063]The aspergillus niger is inoculated with 5% of the inoculation amount in the fermentation medium II. fermentation culture to obtain fermentation culture liquid I., the fermentation culture liquid I. is a ferulita containing a juniper penicillium source and a dehydrogenase of the juniperpenis source of aspergillus niger, and a β - glucosidase of aspergillus niger;

[0064] Trichoderma reticulate according to the amount of inoculation 5% in the fermentation medium I. fermentation culture to obtain fermentation culture ii., the fermentation culture liquid II. is a cellulase containing Trichoderma reedi derived from; and

[0065] The fermentation culture solution I. was compounded with the fermentation culture medium II. according to the volume ratio 1:7 (well mixed) to obtain a complex cellulase line.

[0066] Wherein, the fermentation me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com