Raman sensor and production method thereof

A sensor and graphene technology, applied in the field of cancer diagnosis, can solve the problems of limited application, low sensitivity, weak signal, etc., and achieve the effect of improving sensitivity, increasing Raman signal, and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

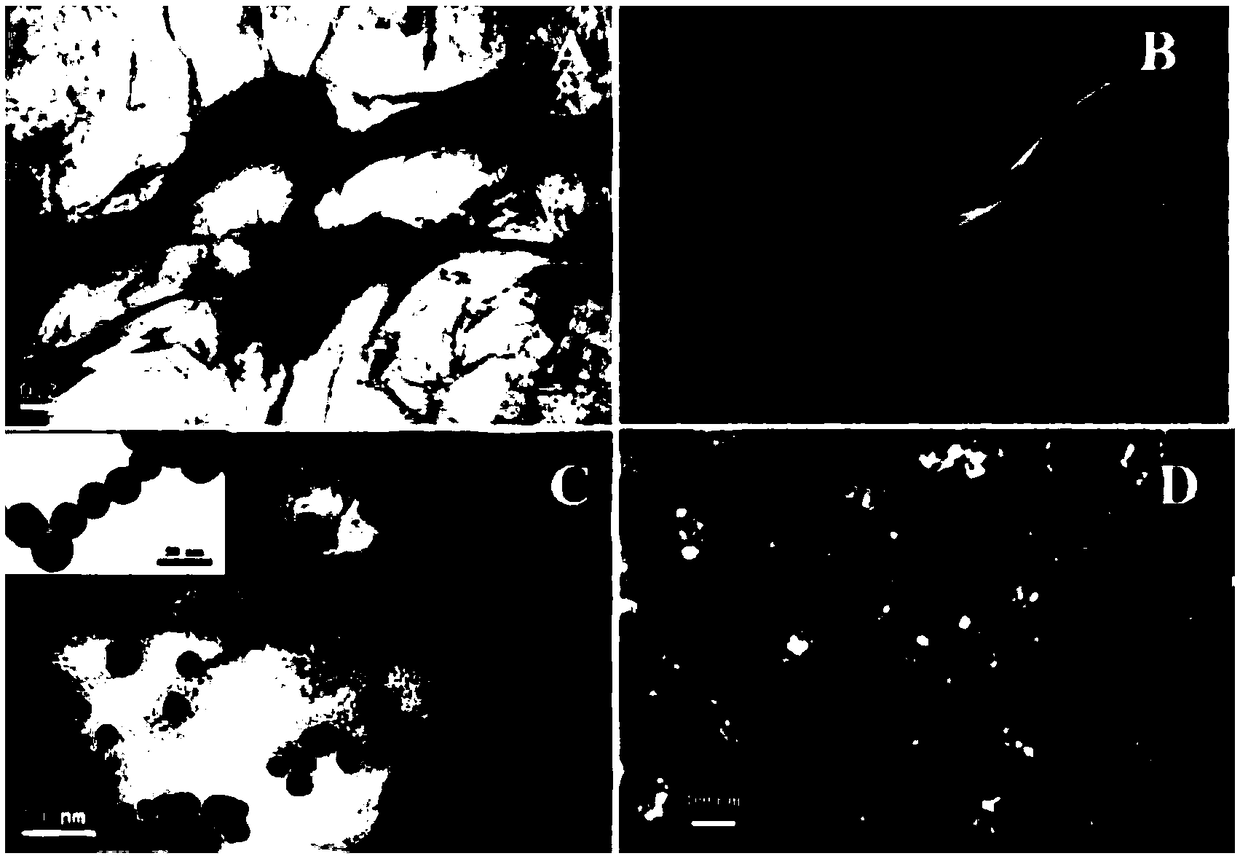

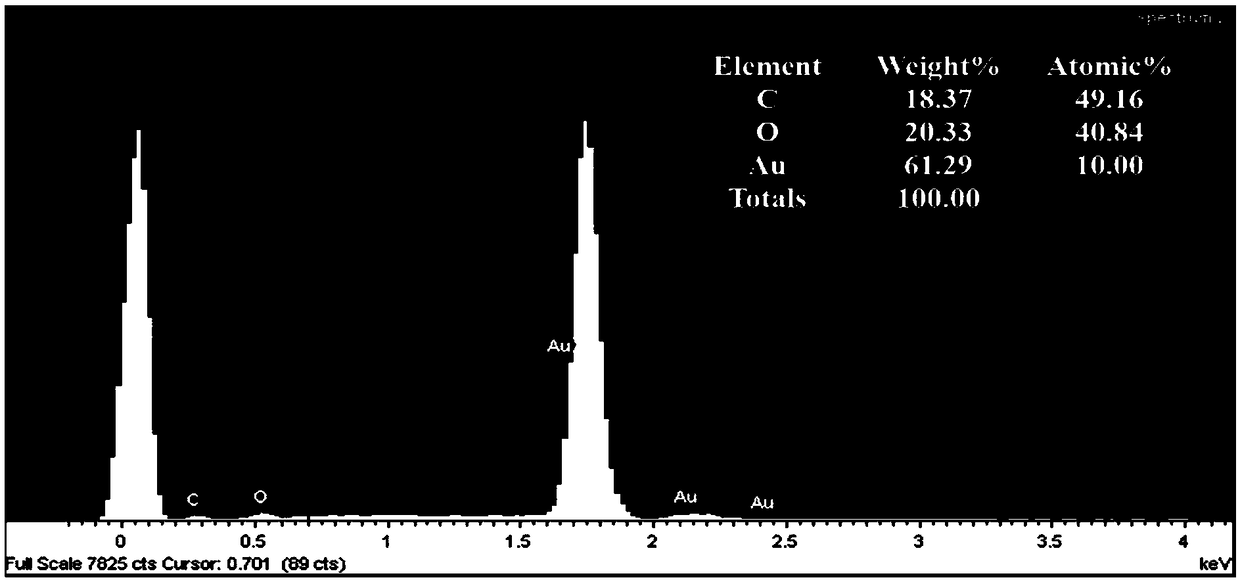

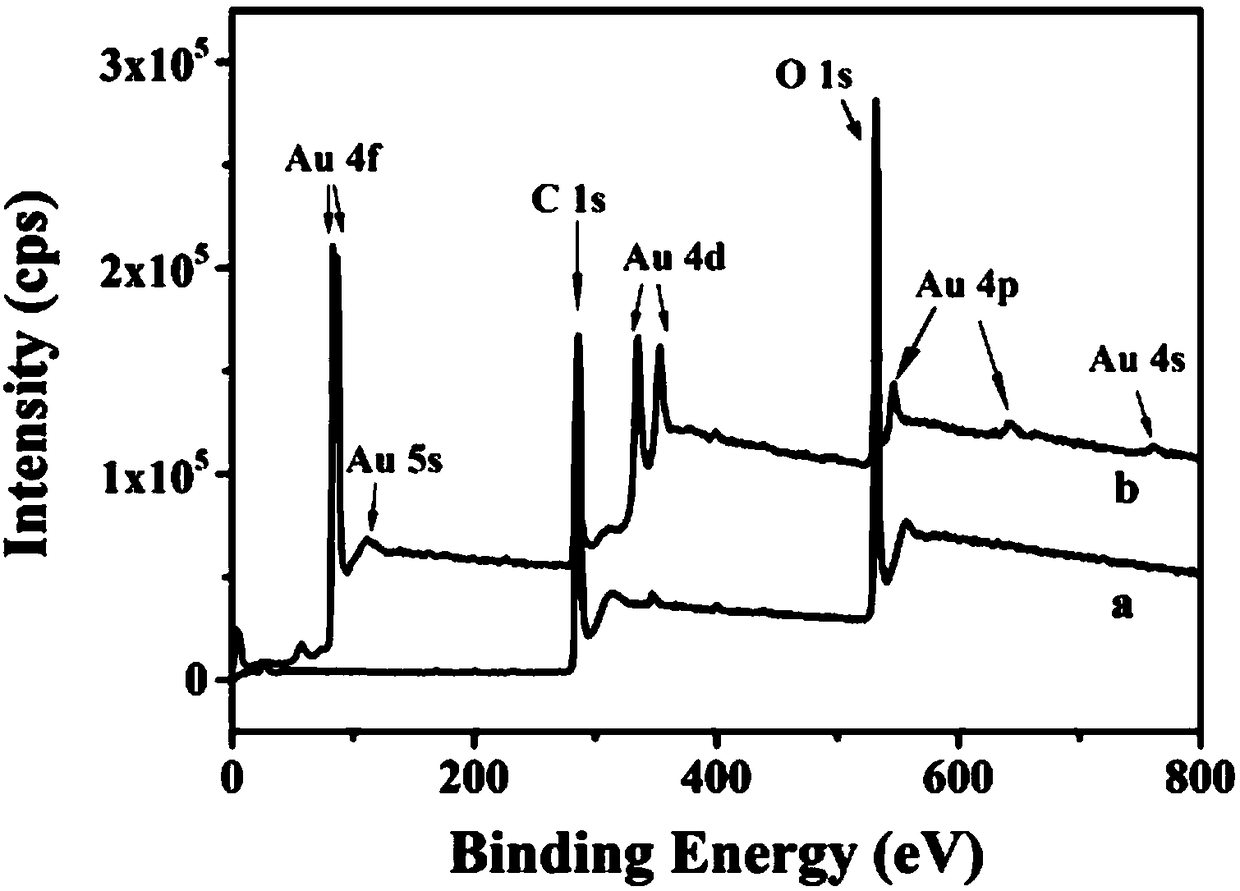

Image

Examples

Embodiment 1

[0032] In this example, all the chemical reagents used were of analytical grade or above. Chlorauric acid (HAuCl 4 4H 2 O), concentrated sulfuric acid, potassium permanganate, concentrated hydrochloric acid and sodium hydroxide (NaOH) were purchased from China National Pharmaceutical Co., Ltd. Rhodamine 6G (C 28 h 31 N 2 o 3 Cl) was purchased from Shanghai Aladdin Reagent Co., Ltd. The 8 amino acid markers used were purchased from SigmaAldrich (Sigma, USA). The deionized water used in the experiment was prepared in real time by Millipore-Q ultrapure water system (Millipore, USA), and the conductivity was not lower than 18.2 MΩcm.

[0033] Preparation of Graphene Oxide (GO)

[0034] The preparation of graphene oxide is carried out according to the common preparation method Hummer method. Briefly, firstly, potassium permanganate (KMnO 4 ) and concentrated sulfuric acid (H 2 SO 4 ) after the graphite flakes are oxidized, followed by ultrasonic peeling, and finally the...

Embodiment 2

[0049] Adopt the reagent identical with embodiment and identical preparation method, difference is:

[0050] (1) Graphene oxide and HAuCl in graphene oxide solution 4 HAuCl in solution 4 The mass ratio is 1:1;

[0051] (2) Add sodium hydroxide under the condition of rotating speed of 300rpm, adjust the pH to 9, then perform hydrothermal reaction at 100°C for 15h, and finally obtain the Raman sensor by centrifugation.

[0052] The Raman sensor obtained in this example was subjected to the same detection as in Example 1, which proved that the Raman sensor had good sensitivity.

Embodiment 3

[0054] Adopt the reagent identical with embodiment and identical preparation method, difference is:

[0055] (1) Graphene oxide and HAuCl in graphene oxide solution 4 HAuCl in solution 4 The mass ratio is 1:10;

[0056] (2) Add sodium hydroxide under the condition of rotating speed of 700rpm, adjust the pH to 13, then perform hydrothermal reaction at 140°C for 10h, and finally obtain the Raman sensor by centrifugation.

[0057] The Raman sensor obtained in this example was subjected to the same detection as in Example 1, which proved that the Raman sensor had good sensitivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Relative molecular mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com