Ozone oxidation catalyst and preparation method thereof

A technology of ozone oxidation and catalyst, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

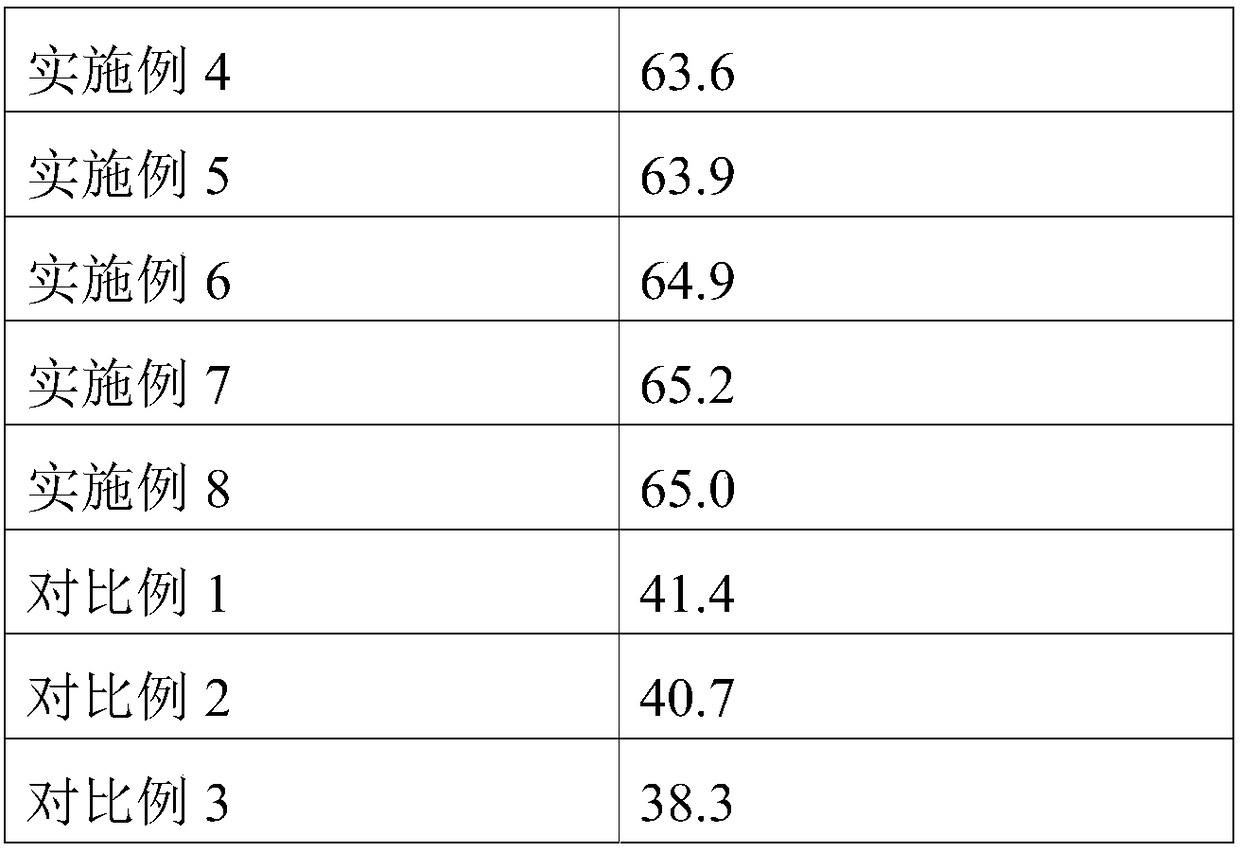

Examples

preparation example Construction

[0025] The preparation method of the ozone oxidation catalyst of an embodiment of the present invention, preparation method comprises the following steps:

[0026] adding an ammonia solution with a pH value of 11.0 to 11.7 into a +4-valent Sn source solution to prepare a precipitation solution;

[0027] The precipitated liquid is filtered and dried to obtain a tin dioxide solid;

[0028] Grinding and mixing tin dioxide solids and barium oxide solids according to the formula ratio to obtain mixed powders;

[0029] The mixed powder is calcined to obtain the catalyst.

[0030] In the catalyst prepared by the above method for preparing the ozone oxidation catalyst, tin dioxide is the main catalyst, and barium oxide plays the role of modifying and modulating the main catalyst in the catalyst. There are L (Lewis) acid and B (Bronsted) acid on the surface of transition metal oxide tin dioxide, and the strong surface acidity directly affects the adsorption and desorption of OH radic...

Embodiment 1

[0042] Weigh SnCl 4 ·5H 2 O (crystal) 35.05g and dissolved in tin chloride solution in 100mL distilled water. Measure 30.91 mL of ammonia water with a molar concentration of 5 mol / L as the ammonia solution. Slowly add ammonia solution dropwise to the tin chloride solution, and use electromagnetic stirring to ensure uniform precipitation. The precipitate in the prepared tin dioxide precipitation solution was in the form of white flocculation, and the tin dioxide precipitation solution was placed in an electric heating constant temperature drying oven, and aged at 353K for 3.0 h. Wash the precipitate with dilute ammonium nitrate solution until it is neutral, filter it under reduced pressure, put the filter cake into a 383K constant temperature drying oven to dry until the tin dioxide solid is in the form of transparent crystals, and then take it out. The molar ratio of tin dioxide: barium oxide is Weigh a certain amount of barium oxide powder and the obtained tin dioxide soli...

Embodiment 2

[0045] Weigh SnCl 4 ·5H 2 O (crystal) 28.04g and dissolved in tin chloride solution in 100mL distilled water. Measure 24.73 mL of ammonia water with a molar concentration of 5 mol / L as the ammonia solution. Slowly add ammonia solution dropwise to the tin chloride solution, and use electromagnetic stirring to ensure uniform precipitation. The precipitate in the prepared tin dioxide precipitation solution was in the form of white flocculation, and the tin dioxide precipitation solution was placed in an electric heating constant temperature drying oven, and aged at 350K for 2.5 hours. Wash the precipitate with dilute ammonium nitrate solution until it is neutral, filter under reduced pressure, put the filter cake in a 380K constant temperature drying oven to dry until the tin dioxide solid is in the form of transparent crystals, and then take it out. The molar ratio of tin dioxide: barium oxide is Weigh a certain amount of barium oxide powder and the prepared tin dioxide solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com