Formaldehyde removal coating and preparation method thereof

A paint and formaldehyde technology, applied in the field of environmental protection paint and its preparation, can solve the problems of shell pollution and harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

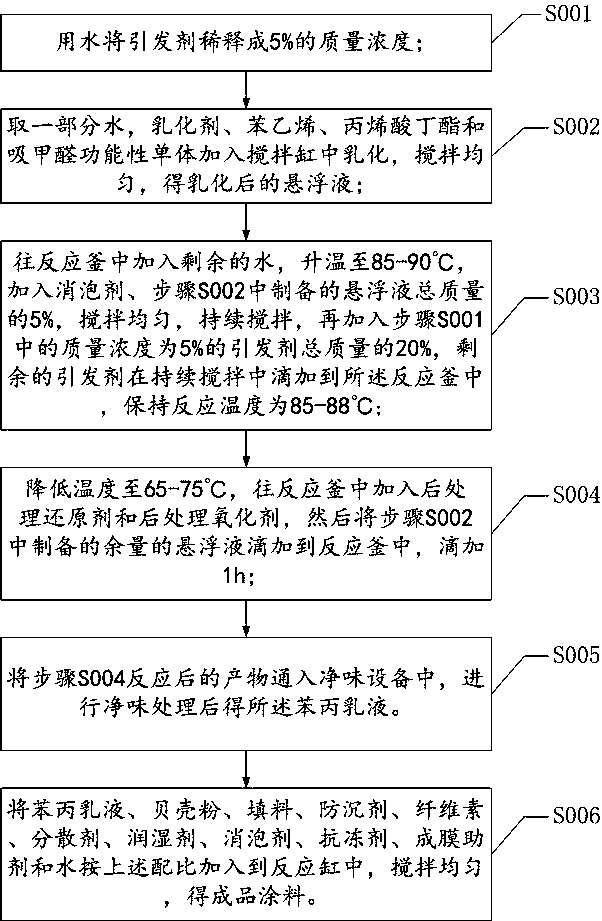

Method used

Image

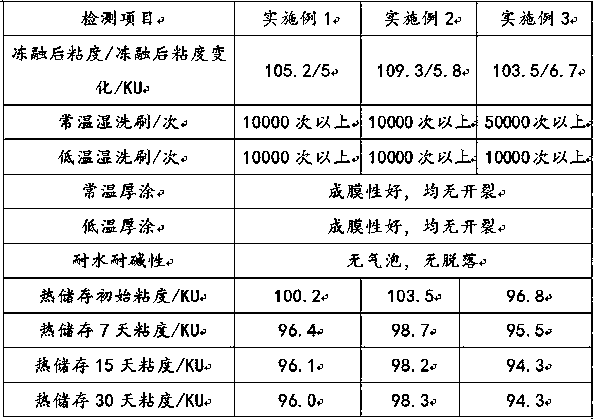

Examples

Embodiment 1

[0091] A formaldehyde removal paint, calculated in parts by weight, including:

[0092] 15 parts of styrene-acrylic emulsion,

[0093] 20 parts of shell powder,

[0094] 0.1 part of anti-settling agent,

[0095] 2 parts of cellulose,

[0096] 0.3 parts of dispersant,

[0097] Wetting agent 0.5 parts,

[0098] 0.2 parts of defoamer,

[0099] Antifreeze 0.5 parts,

[0100] 1 part of film forming aid,

[0101] Packing 16 parts,

[0102] 30 parts of water.

[0103] Wherein, the styrene-acrylic emulsion is calculated in parts by weight and includes:

[0104] 25 parts of styrene,

[0105] 20 parts of butyl acrylate,

[0106] 5 parts of formaldehyde-absorbing functional monomer,

[0107] 1.5 parts of emulsifier,

[0108] 0.1 part of initiator,

[0109] 0.05 parts of post-treatment reducing agent,

[0110] 0.05 parts of post-treatment oxidant,

[0111] 0.01 parts of defoamer,

[0112] 45 parts of water.

[0113] The filler is calculated in parts by weight and includes:

[0114] 8 parts of titanium dioxide,

[011...

Embodiment 2

[0125] A formaldehyde removal paint, calculated in parts by weight, including:

[0126] 10 parts of styrene-acrylic emulsion,

[0127] 10 servings of shell powder,

[0128] Anti-settling agent 0.05 parts,

[0129] 2 parts of cellulose,

[0130] 0.1 part of dispersant,

[0131] Wetting agent 0.1 part,

[0132] 0.1 part of defoamer,

[0133] 1 part of antifreeze,

[0134] 28 parts of filler,

[0135] 20 parts of water.

[0136] Wherein, the styrene-acrylic emulsion is calculated in parts by weight and includes:

[0137] 20 parts of styrene,

[0138] 30 parts of butyl acrylate,

[0139] 8 parts of formaldehyde-absorbing functional monomer,

[0140] 3 parts of emulsifier,

[0141] 0.3 parts of initiator,

[0142] 0.03 parts of post-treatment reducing agent,

[0143] 0.03 parts of post-treatment oxidant,

[0144] 0.03 parts of defoamer,

[0145] 50 parts of water.

[0146] The filler is calculated in parts by weight and includes:

[0147] 10 parts of titanium dioxide,

[0148] 8 parts of kaolin,

[0149] 10 pa...

Embodiment 3

[0158] A formaldehyde removal paint, calculated in parts by weight, including:

[0159] 20 parts of styrene-acrylic emulsion,

[0160] 30 servings of shell powder,

[0161] 0.3 parts of anti-settling agent,

[0162] 6 parts of cellulose,

[0163] Dispersant 0.5 part,

[0164] 0.3 parts of wetting agent,

[0165] 0.3 parts of defoamer,

[0166] 2 parts of antifreeze,

[0167] 2 parts of film forming aids,

[0168] 7 parts of filler,

[0169] 40 parts of water.

[0170] Wherein, the styrene-acrylic emulsion is calculated in parts by weight and includes:

[0171] 30 parts of styrene,

[0172] 10 parts of butyl acrylate,

[0173] 4 parts of formaldehyde-absorbing functional monomer,

[0174] 5 parts of emulsifier,

[0175] 0.2 parts of initiator,

[0176] 0.1 part of post-treatment reducing agent,

[0177] 0.1 part of post-treatment oxidant,

[0178] Defoamer 0.02 parts,

[0179] 60 parts of water.

[0180] The filler is calculated in parts by weight and includes:

[0181] 5 parts of titanium dioxide,

[0182...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com