Epoxy expansion type fireproof coating enhanced by various carbon-based materials

A technology of carbon-based materials and fire-resistant coatings, applied in fire-resistant coatings, epoxy resin coatings, anti-corrosion coatings, etc., can solve the problems of easy cracking and falling off of epoxy coatings, achieve excellent anti-corrosion performance, prevent cracking and falling off, and have good effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

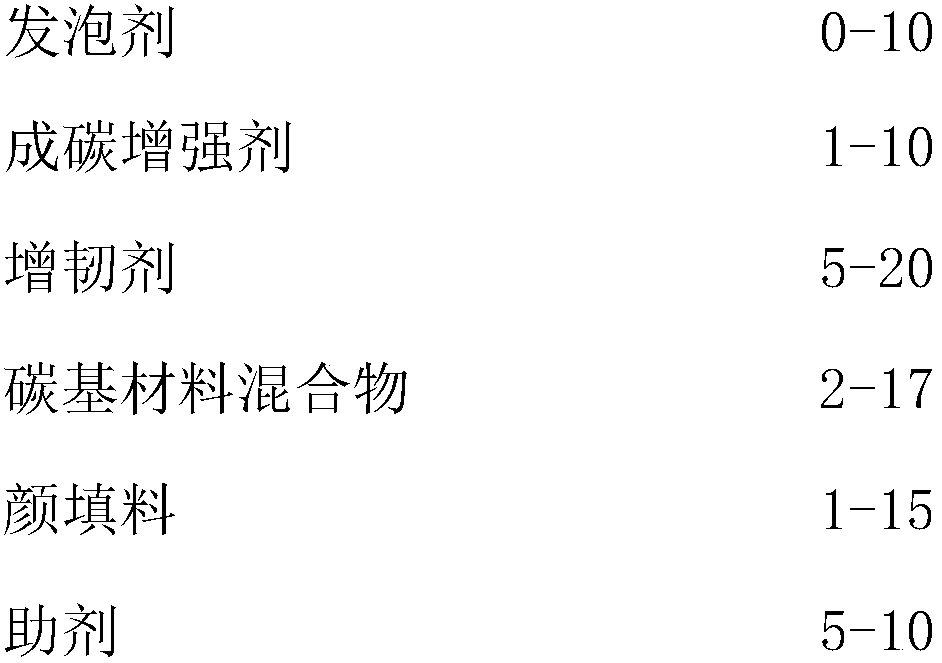

[0027] An epoxy intumescent fireproof coating reinforced by a variety of carbon-based materials, consisting of two components, A and B. The formula of A and B components is as follows:

[0028] Component A: 30 parts of epoxy resin E51, 35 parts of ammonium polyphosphate, 5 parts of pentaerythritol, 5 parts of melamine, 2 parts of zinc borate, 3 parts of glass fiber, 10 parts of triphenyl phosphate, 1 part of graphene, 2 parts Carbon fiber, 5 parts of expanded graphite, 8 parts of titanium dioxide, 7 parts of fumed silica;

[0029] Component B: 45 parts of phenalkamine, 20 parts of aluminum hydroxide, 15 parts of fly ash floating beads, 7 parts of hydrogenated castor oil;

[0030] Components A and B are mixed in a ratio of 3:1.

Embodiment 2

[0032] An epoxy intumescent fireproof coating reinforced by a variety of carbon-based materials, consisting of two components, A and B. The formula of A and B components is as follows:

[0033] Component A: 40 parts of epoxy resin E51, 20 parts of ammonium polyphosphate, 1 part of dipentaerythritol, 1 part of melamine, 1 part of kaolin, 0.9 parts of glass fiber, 20 parts of triphenyl phosphate, 0.1 part of graphene, 1 part Carbon fiber, 1 part of expanded graphite, 1 part of titanium dioxide, 1 part of carbon black, 8 parts of fumed silica;

[0034] Component B: 30 parts of phenalkamine, 5 parts of polyetheramine, 20 parts of aluminum hydroxide, 25 parts of ceramic microbeads, 5 parts of hydrogenated castor oil;

[0035] Components A and B are mixed in a ratio of 3:1.

Embodiment 3

[0037] An epoxy intumescent fireproof coating reinforced by a variety of carbon-based materials, consisting of two components, A and B. The formula of A and B components is as follows:

[0038] Component A: 20 parts of epoxy resin E51, 50 parts of ammonium polyphosphate, 4 parts of pentaerythritol, 4 parts of dipentaerythritol, 10 parts of melamine, 5 parts of zinc oxide, 5 parts of high silica fiber, 5 parts of triphenyl phosphate, 2 parts of graphene, 5 parts of carbon fiber, 10 parts of expanded graphite, 9 parts of titanium dioxide, 4 parts of carbon black, 5 parts of fumed silica;

[0039] Component B: 60 parts of phenalkamine, 10 parts of magnesium hydroxide, 10 parts of vitrified microbeads, 10 parts of hydrogenated castor oil;

[0040] Components A and B are mixed in a ratio of 3:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com