Formula and production process of a complex manganese-aluminum bronze welding wire

A manganese-aluminum bronze and welding wire technology, applied in welding equipment, manufacturing tools, welding media, etc., can solve the problems of electroplating environmental pollution that cannot be ignored, corrosion resistance cannot be satisfied, capillary pinholes are inevitable, and the operation steps are simple and convenient , increase the roundness and flatness, the effect of perfect steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

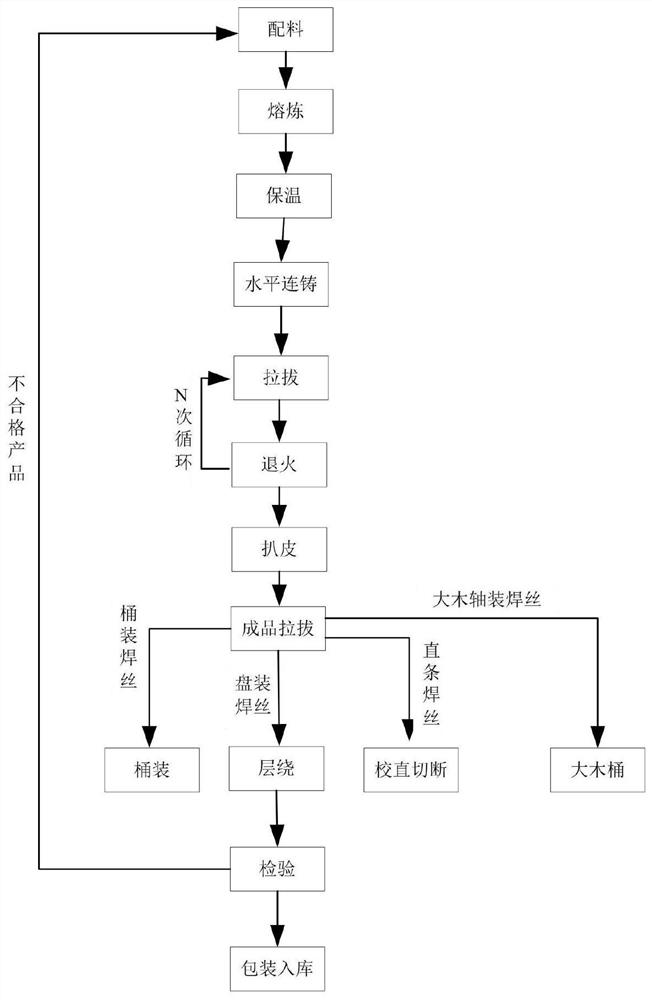

Image

Examples

Embodiment 1

[0032] A formula of complex manganese-aluminum bronze welding wire, its raw material formula includes the following components:

[0033] Mn: 8%;

[0034] Al: 6.5%;

[0035] Fe: 1.2%;

[0036] Ni: 1.5%;

[0037] Si: 0.03%;

[0038] Cu: 82.77%.

[0039] Preferably, the complex manganese-aluminum bronze welding wire is used for surfacing welding on steel.

[0040] Preferably, the surfacing layer of the complex manganese-aluminum bronze welding wire has a Brinell hardness of HB200, a tensile strength of 550 MPa, a solidus of 960°C, a liquidus of 1000°C, an elongation of 25%, and a density of 7.62kg / dm 2 .

[0041] A production process of complex manganese-aluminum bronze welding wire, comprising the steps of:

[0042] (1) Ingredients: weighed according to the chemical composition ratio of the alloy, 800 kg per batch;

[0043] (2) Melting: carried out in a power frequency induction melting furnace, the melting temperature is 1080-1130°C, and the melting time is about 1.5h;...

Embodiment 2

[0051] A formula for complex manganese-aluminum bronze welding wire, the raw material formula includes:

[0052] Mn: 10%;

[0053] Al: 8.5%;

[0054] Fe: 3.0%;

[0055] Ni: 3.0%;

[0056] Si: 0.1%;

[0057] Cu: 75.4%.

[0058] Preferably, the complex manganese-aluminum bronze welding wire is used for surfacing welding on steel.

[0059] Preferably, the surfacing layer of the complex manganese-aluminum bronze welding wire has a Brinell hardness of HB250, a tensile strength of 650 MPa, a solidus of 950°C, a liquidus of 990°C, an elongation of 15%, and a density of 7.52kg / dm 2 .

[0060] A production process of complex manganese-aluminum bronze welding wire, comprising the steps of:

[0061] (1) Ingredients: weighed according to the chemical composition ratio of the alloy, 800 kg per batch;

[0062] (2) Melting: carried out in a power frequency induction melting furnace, the melting temperature is 1080-1130°C, and the melting time is about 1.5h;

[0063] (3) Heat preser...

Embodiment 3

[0070] A formula of complex manganese-aluminum bronze welding wire, its raw material formula includes the following components:

[0071] Mn: 9%;

[0072] Al: 7.5%;

[0073] Fe: 2.1%;

[0074] Ni: 2.25%;

[0075] Si: 0.065%;

[0076] Cu: 79.085%.

[0077] Preferably, the complex manganese-aluminum bronze welding wire is used for surfacing welding on steel.

[0078] Preferably, the surfacing layer of the complex manganese-aluminum bronze welding wire has a Brinell hardness of HB230, a tensile strength of 600 MPa, a solidus of 955°C, a liquidus of 995°C, an elongation of 20%, and a density of 7.57kg / dm 2 .

[0079] A production process of complex manganese-aluminum bronze welding wire, comprising the steps of:

[0080] (1) Ingredients: weighed according to the chemical composition ratio of the alloy, 800 kg per batch;

[0081] (2) Melting: carried out in a power frequency induction melting furnace, the melting temperature is 1080-1130°C, and the melting time is about 1.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com