Modified dust-collecting powder, as well as preparation method and application thereof

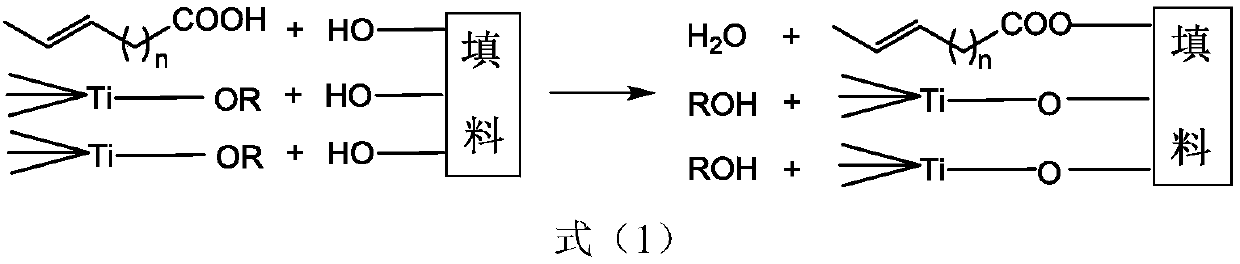

A dust powder and modification technology, which is applied in the field of modified dust collection powder and its preparation, to achieve the effects of reducing dosage, improving economic value, and satisfying coupling and filling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Inject the 800 mesh (15 micron) fine particle dust collection powder into the closed kneader through the pipeline, start stirring, and at the same time spray the modifier mist directly on the surface of the fine particle dust collection powder from the metering nozzle installed on the top of the kneader Dispersion (10 kg of silane coupling agent and titanate coupling agent, 10 kg of neutralizing agent, and 5 kg of solvent oil and epoxidized soybean oil per ton of dust collection powder), and in a kneader Heating and kneading at 80°C for 30 minutes, cooling and packaging to obtain fine particle modified dust collection powder, which can be used as a plastic filler product.

Embodiment 2

[0053] Inject the 3000 mesh (4 micron) superfine particle dust collection powder into the closed kneader through the pipeline, start stirring, and at the same time spray the modifier directly on the surface of the ultrafine particle dust collection powder from the metering nozzle installed on the top of the kneader Spray dispersion (15 kg of titanate coupling agent and aluminate coupling agent, 15 kg of neutralizing agent, 8 kg of alcohol, triethanolamine and allyloxypropylene oxide per ton of dust collection powder Mixed solution), heated and kneaded at 80°C in a kneader for 30 minutes, cooled and packaged to obtain ultrafine particle modified dust collection powder, which can be used as a medium-to-high-grade rubber filler product.

Embodiment 3

[0055] Inject 3500 mesh (3.5 micron) ultra-fine dust collection powder into the closed kneader through the pipeline, start stirring, and at the same time spray the modifier directly on the surface of the ultra-fine dust collection powder from the metering nozzle installed on the top of the kneader Spray dispersion (a mixture of 20 kg of zirconate coupling agent and aluminate coupling agent, 20 kg of neutralizing agent, 12 kg of alcohol and glycidyl ether per ton of dust collection powder), and kneading Heating and kneading at 80°C in the machine for 30 minutes, cooling and packaging to obtain ultra-fine particle modified dust collection powder, the surface of which is completely covered by the modifier and has a semi-reinforcing effect. It can be used as a high-quality rubber filler product and Special filler for coatings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com