Preparation method for constructing two-dimensional metal-organic frameworks (MOFs) nano-hydrolysis electrocatalyst based on foamy copper and application of two-dimensional MOFs nano-hydrolysis electrocatalyst to water electrolysis for hydrogen evolution

A technology of metal-organic framework and electrocatalyst, which is applied in the direction of electrolysis components, electrolysis process, electrodes, etc., to achieve the effects of simple and controllable preparation process, good electrical conductivity, excellent hydrogen evolution performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing a two-dimensional metal-organic framework nanometer hydrolysis electrocatalyst using foamed copper as a substrate, comprising the following steps:

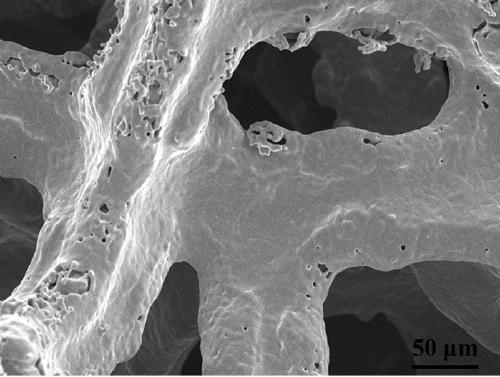

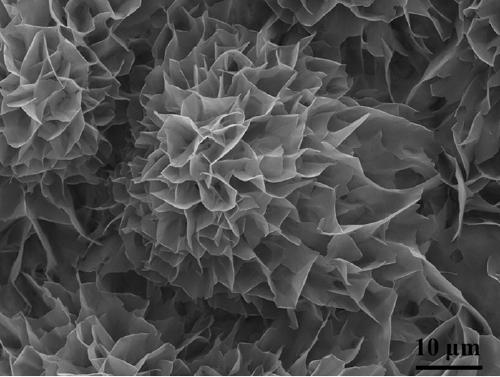

[0033] a) Preparation of copper phosphate nanosheets: Cut foamed copper with a thickness of 0.16 mm into blocks with a length and width of 30×20 mm, soak in 1 mol / L HCl and ultrasonically clean for 15 min, then rinse with distilled water and ethanol respectively 3 minutes. Then soak the pretreated copper foam in 2 mL of (NH 4 ) 2 S 2 o 8 (0.1 mol / L) and 2 mL of Na 2 HPO 4(0.4mol / L) in 20 mL aqueous solution, reacted at 20°C for 1 h, took it out, rinsed with deionized water, and dried in vacuum at 50°C for 2 h to obtain a substrate with copper phosphate nanosheets grown on the surface.

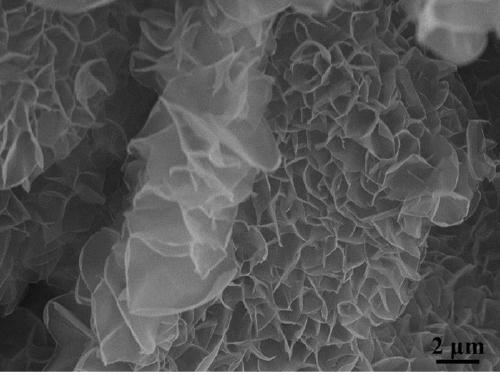

[0034] b) Preparation of copper-containing MOFs nanosheets: Dissolve 0.84 g of trimesic acid in 40 mL of ethanol solution (0.10 mol / L) in a polyvinyl fluoride reactor, and grow copper phosphate nanosheets in step...

Embodiment 2

[0037] A method for preparing a two-dimensional metal-organic framework nanometer hydrolysis electrocatalyst using foamed copper as a substrate, comprising the following steps:

[0038] a) Preparation of copper phosphate nanosheets: Cut the foamed copper with a thickness of 0.16 mm into a block with a length and width of 30×20 mm, soak it in 3 mol / L HCl and ultrasonically clean it for 15 min, then wash it with distilled water and ethanol respectively 3 minutes. Then soak the pretreated copper foam in 3 mL of (NH 4 ) 2 S 2 o 8 (0.3 mol / L) and 3 mL of Na 2 HPO 4 (0.6 mol / L) in 20 mL aqueous solution, reacted at 30 °C for 2 h, took it out, rinsed with deionized water, and dried in vacuum at 50 °C for 2 h to obtain a substrate with copper phosphate nanosheets grown on the surface.

[0039] b) Preparation of copper-containing MOFs nanosheets: Dissolve 1.26 g of trimesic acid in 40 mL of ethanol solution (0.15 mol / L) in a polyvinyl fluoride reactor, and grow copper phosphate n...

Embodiment 3

[0042] A method for preparing a two-dimensional metal-organic framework nanometer hydrolysis electrocatalyst using foamed copper as a substrate, comprising the following steps:

[0043] a) Preparation of copper phosphate nanosheets: Cut the foamed copper with a thickness of 0.16 mm into blocks with a length and width of 30×20 mm, immerse them in 5 mol / L HCl and ultrasonically clean them for 15 min, then wash them with distilled water and ethanol respectively 3 minutes. Then soak the pretreated copper foam in 4.5 mL of (NH 4 ) 2 S 2 o 8 (0.6 mol / L) and 4.5 mL of Na 2 HPO 4 (0.7 mol / L) in 20 mL aqueous solution, reacted at 50 °C for 3 h, took it out, rinsed with deionized water, and dried in vacuum at 50 °C for 2 h to obtain a substrate with copper phosphate nanosheets grown on the surface.

[0044] b) Preparation of copper-containing MOFs nanosheets: 1.81 g of 2-aminoterephthalic acid was fully dissolved in 40 mL of methanol solution (0.25 mol / L) in a polyvinyl fluoride r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com