Effervescent tablet starter and preparation method thereof

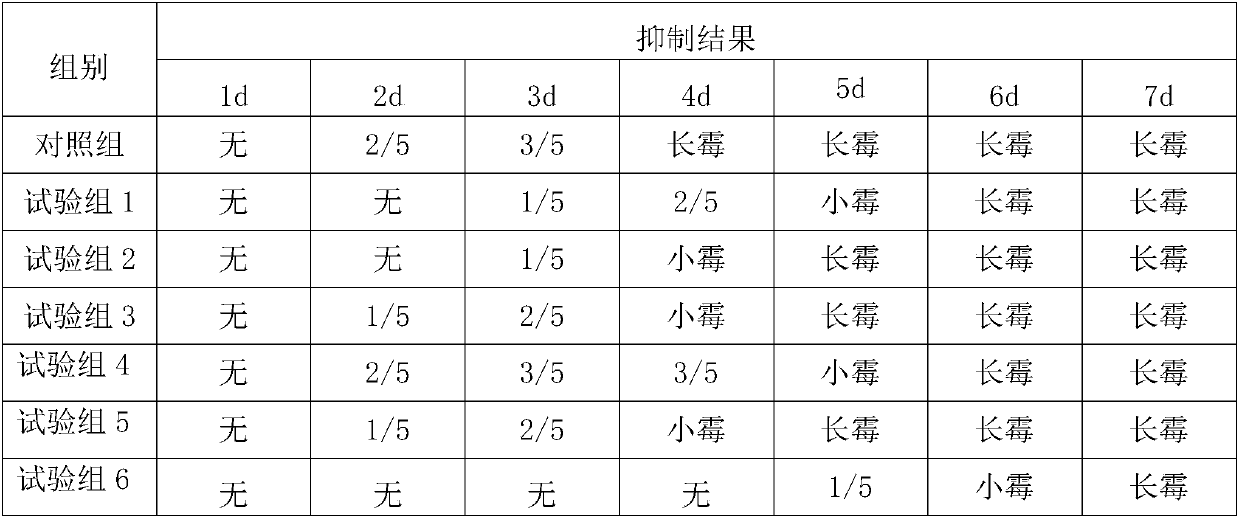

A fermentation agent and effervescent tablet technology, applied in the field of bioengineering, can solve the problem of reducing the number of viable bacteria, and achieve the effects of high number of viable bacteria, inhibiting the proliferation of miscellaneous bacteria, and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] An effervescent tablet starter, made according to the following parts by weight: 20 parts of fermented bacteria powder, 35 parts of tartaric acid, 25 parts of sodium bicarbonate, 10 parts of dextrin, 10 parts of lactose, 5 parts of mannitol, polyethylene glycol 6000 5 parts, micronized silica gel 5 parts.

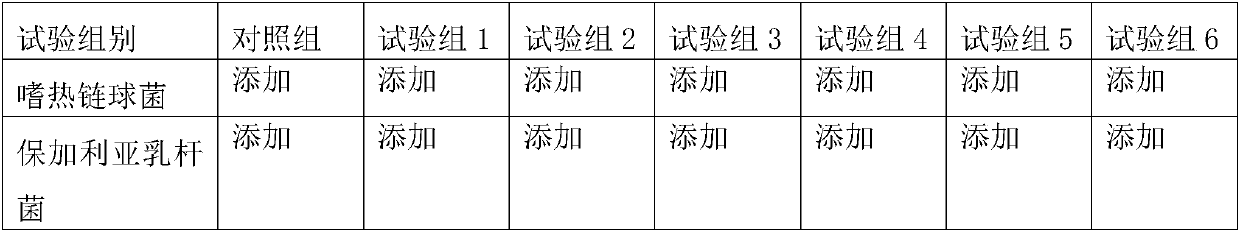

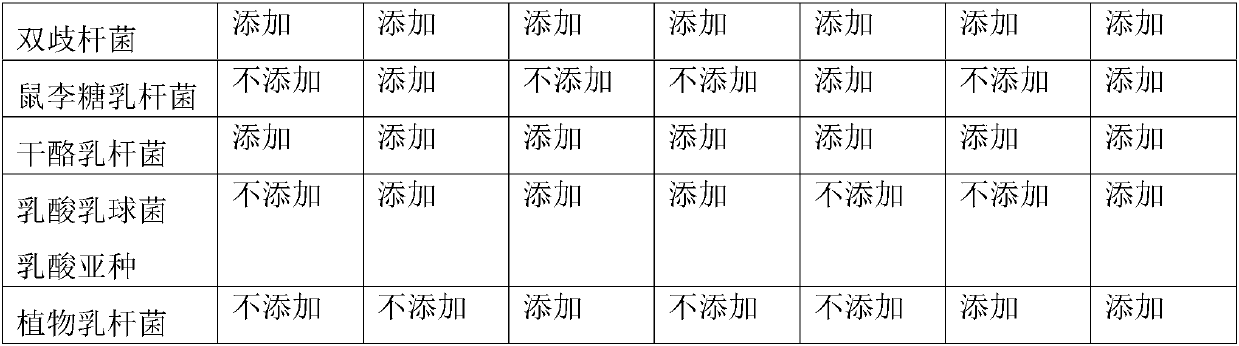

[0024] Wherein, the fermented bacteria powder is composed of multi-strain fermented bacterial agent A and multi-strain fermented bacterial agent B, wherein the ratio of the weight and number of each component of the multi-strain fermented agent A is, Streptococcus thermophilus: Lactobacillus bulgaricus: double Mycobacterium: Lactobacillus casei: Lactococcus lactis lactic acid subspecies=1:1:1.5:1:1.5, the ratio of the weight and number of each component of described multi-strain starter B is, Lactobacillus plantarum: Lactobacillus rhamnosus= 1:1.

[0025] Prepared as follows:

[0026] (1) After each strain is activated at 37°C, it is inoculated in the culture mediu...

Embodiment 2

[0029] An effervescent tablet starter, made according to the following parts by weight: 15 parts of fermented bacteria powder, 30 parts of tartaric acid, 20 parts of sodium bicarbonate, 5 parts of dextrin, 5 parts of lactose, 1 part of mannitol, polyethylene glycol 6000 1 part, micro powder silica gel 1 part.

[0030] Wherein, the fermented bacteria powder is composed of multi-strain fermented bacterial agent A and multi-strain fermented bacterial agent B, wherein the ratio of the weight and number of each component of the multi-strain fermented agent A is, Streptococcus thermophilus: Lactobacillus bulgaricus: double Mycobacterium: Lactobacillus casei: Lactococcus lactis lactic acid subspecies=1:1:1.5:1:1.5, the ratio of the weight and number of each component of described multi-strain starter B is, Lactobacillus plantarum: Lactobacillus rhamnosus= 1:1.

[0031] Prepared as follows:

[0032] (1) After each strain is activated at 37°C, it is inoculated in the culture medium (...

Embodiment 3

[0035] An effervescent tablet starter, made according to the following parts by weight: 18 parts of fermented bacteria powder, 32 parts of tartaric acid, 23 parts of sodium bicarbonate, 8 parts of dextrin, 9 parts of lactose, 3 parts of mannitol, polyethylene glycol 6000 3 parts, micronized silica gel 2 parts.

[0036] Wherein, the fermented bacteria powder is composed of multi-strain fermented bacterial agent A and multi-strain fermented bacterial agent B, wherein the ratio of the weight and number of each component of the multi-strain fermented agent A is, Streptococcus thermophilus: Lactobacillus bulgaricus: double Mycobacterium: Lactobacillus casei: Lactococcus lactis lactic acid subspecies=1:1:1.5:1:1.5, the ratio of the weight and number of each component of described multi-strain starter B is, Lactobacillus plantarum: Lactobacillus rhamnosus= 1:1.

[0037] Prepared as follows:

[0038] (1) After each strain is activated at 37°C, it is inoculated in the culture medium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com