Application of SMXP-58 bacterial strain in aspect of degrading cellulose in tobacco leaves

A SMXP-58, cellulose technology, applied in the application, tobacco, bacteria and other directions, can solve the problem of irreversible influence on the quality of cigarette products, and achieve the effect of promoting the quality improvement of cigarette raw materials, shortening the processing period, and degrading the cellulose content well. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In order to use the SMXP-58 strain to degrade cellulose in tobacco leaves, it is first necessary to prepare the strain into an easy-to-use bacterial agent, and the specific preparation process is as follows.

[0023] (1) Activated strains: put the SMXP-58 strain on the LB plate, and activate it in a biochemical climate chamber at 37°C for 1 day;

[0024] (2) Preparation of seed liquid: Scrape the bacteria cultured in step (1) in the ultra-clean workbench, inoculate in a 18×180 test tube containing 5 mL of liquid LB medium, and place on a shaker at 30°C and 150 rpm Overnight culture;

[0025] (3) Expansion culture: Transfer the seed solution in step (2) to a sterile 250mL Erlenmeyer flask containing 100mL liquid LB medium at the ratio of 1 mL bacterial suspension / 100 ml LB medium (1% volume ratio) medium, 30°C, 150 rpm, cultured to OD 600 = about 2.0;

[0026] (4) Preparation of bacterial agent: Centrifuge the bacterial solution in step (3) at 3600 rpm for 10 minutes,...

Embodiment 2

[0028] When utilizing the bacterial agent prepared in the embodiment 1 to process tobacco leaves, the concrete steps are:

[0029] Take the tobacco leaves after extracting the tobacco stems, divide them into sheets, and then evenly divide them into multiple portions, each portion is 100 g;

[0030] According to the tobacco leaf mass ratio of 2%, the microbial inoculant agent prepared in Example 1 is evenly sprayed on the surface of the treated tobacco leaf with a sprayer, and then the moisture content of the tobacco leaf is adjusted to 25%; Treat for 20 minutes to inactivate the bacteria and the cellulase produced by them.

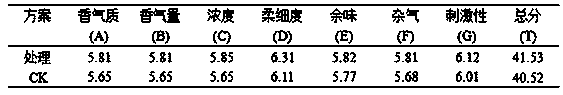

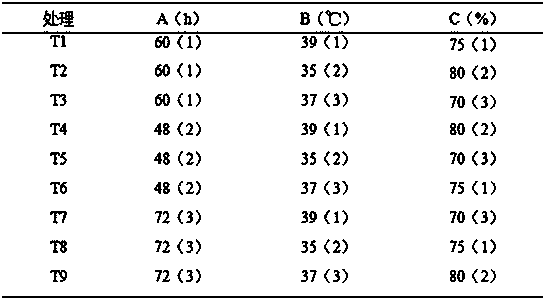

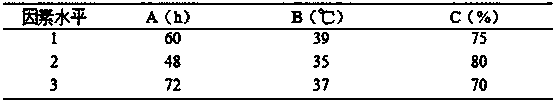

[0031] In order to determine the temperature and humidity conditions and time of the optimal effect of the bacterial agent, the inventors took the fermentation time, fermentation temperature, and fermentation humidity as influencing factors respectively, and carried out a three-factor level design. The specific design is as follows:

[0032] Table 1 Facto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com