Mousse cream and preparation method thereof

A polyglycerol, stearate technology, applied in the field of skin care products, can solve the problems of skin aging, dry skin, rough skin and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

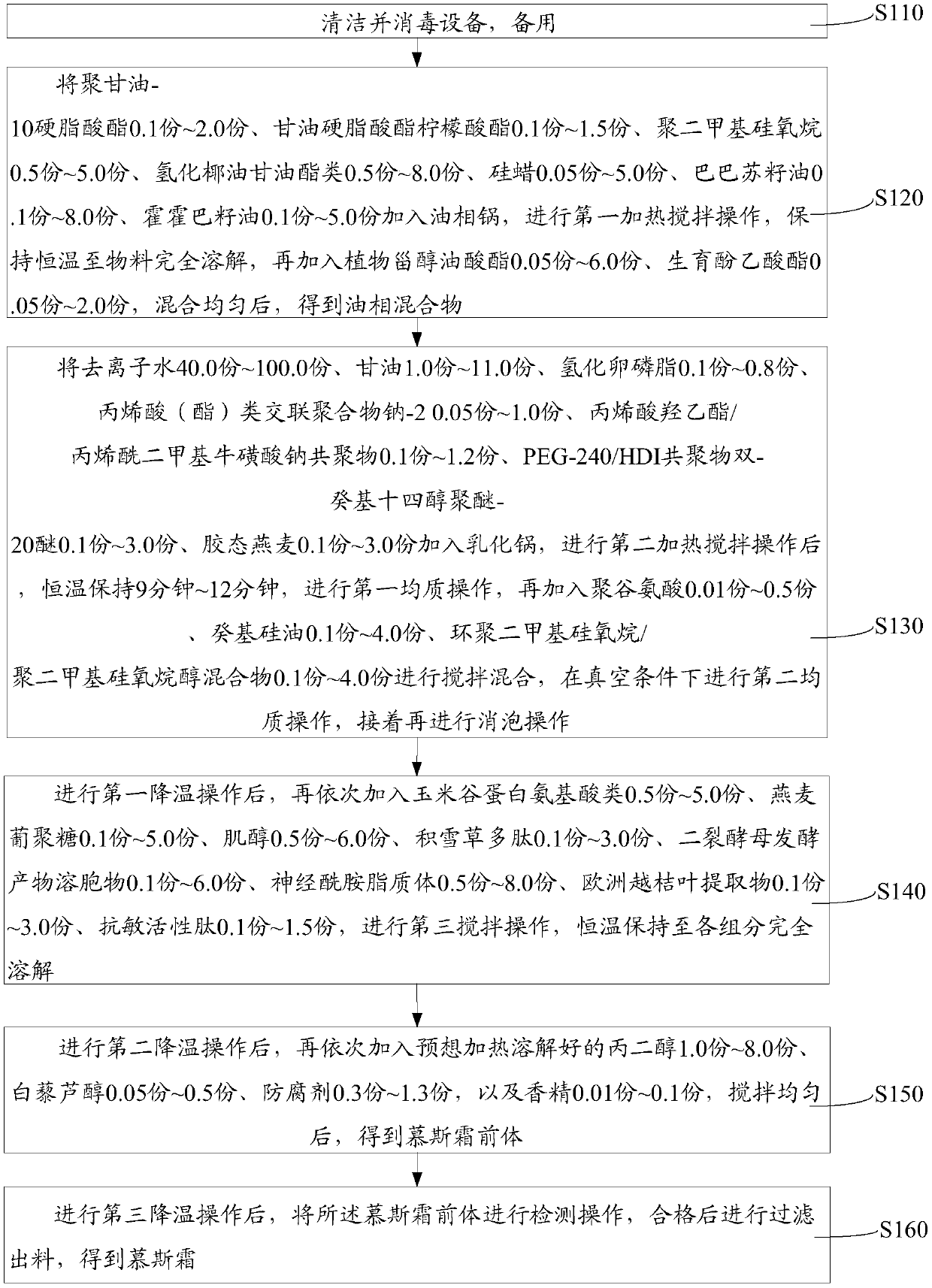

[0081] see figure 1 , the preparation method of the mousse cream of an embodiment, comprises the following steps:

[0082] S110. Clean and disinfect the equipment, and set it aside.

[0083]In order to ensure the quality of the prepared mousse cream and avoid contamination by pollutants, it is first necessary to clean and disinfect the equipment used in the preparation.

[0084] S120, 0.1-2.0 parts of polyglyceryl-10 stearate, 0.1-1.5 parts of glyceryl stearate citrate, 0.5-5.0 parts of polydimethylsiloxane, hydrogenated cocoglycerides Add 0.5-8.0 parts, 0.05-5.0 parts of silicon wax, 0.1-8.0 parts of babassu seed oil, and 0.1-5.0 parts of jojoba seed oil into the oil phase pot, perform the first heating and stirring operation, and keep the temperature until the material is completely dissolve, and then add 0.05 to 6.0 parts of phytosterol oleate and 0.05 to 2.0 parts of tocopheryl acetate, and mix uniformly to obtain an oil phase mixture.

[0085] By adding 0.1 to 2.0 part...

Embodiment 1

[0098] Clean and sanitize equipment, ready for use;

[0099] Polyglyceryl-10 stearate 1.0kg, glyceryl stearate citrate 0.6kg, polydimethylsiloxane 3.0kg, hydrogenated cocoglycerides 5.0kg, silicone wax 3.0kg, babassu seeds Add 3.0kg of oil and 2.0kg of jojoba seed oil into the oil phase pot, perform the first heating and stirring operation at 70°C, keep the constant temperature until the materials are completely dissolved, then add 2.0kg of phytosterol oleate and tocopheryl acetic acid 0.5kg of ester, after mixing uniformly, obtains the oil phase mixture;

[0100] 43.69kg of deionized water, 8.0kg of glycerin, 0.2kg of hydrogenated lecithin, 0.4kg of acrylic acid (ester) cross-linked polymer sodium-2, 0.6kg of hydroxyethyl acrylate / sodium acryloyldimethyl taurate copolymer , 1.5kg of PEG-240 / HDI copolymer bis-decyltetradeceth-20 ether, 1.0kg of colloidal oatmeal were added to the emulsification pot, and at a temperature of 80°C, after the second heating and stirring operation...

Embodiment 2

[0105] Clean and sanitize equipment, ready for use;

[0106] Polyglyceryl-10 stearate 1.0kg, glyceryl stearate citrate 0.6kg, polydimethylsiloxane 3.0kg, hydrogenated cocoglycerides 3.0kg, silicone wax 3.0kg, babassu seeds Add 3.0kg of oil and 1.0kg of jojoba seed oil into the oil phase pot, perform the first heating and stirring operation at 70°C, keep the constant temperature until the materials are completely dissolved, then add 2.0kg of phytosterol oleate and tocopheryl acetic acid Ester 1.0kg, after mixing uniformly, obtains the oil phase mixture;

[0107]42.14kg of deionized water, 8.0kg of glycerin, 0.2kg of hydrogenated lecithin, 0.4kg of acrylic acid (ester) crosslinked polymer sodium-2, 0.6kg of hydroxyethyl acrylate / sodium acryloyldimethyl taurate copolymer 1.5kg of PEG-240 / HDI copolymer bis-decyltetradeceth-20 ether and 1.0kg of colloidal oatmeal were added to the emulsification pot. Minutes, carry out the first homogeneous operation, then add polyglutamic acid 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com