Titanium alloy artificial joint with biolubricating surface layer and preparation method thereof

A technology of artificial joints and titanium alloys, applied in coatings, tissue regeneration, medical science, etc., can solve problems affecting quality and service life, high wear debris, adverse physiological reactions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

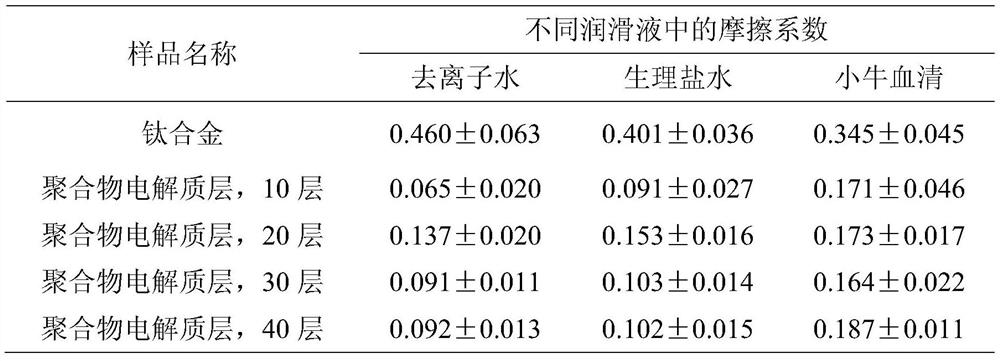

Examples

preparation example Construction

[0038] Titanium alloy artificial joint preparation method with biological lubrication surface, the following steps:

[0039] (1) Preparation of Polyelectrolyte Solution: Futured Polyci Electrolyte Solution and Polyanion Electrolyte Solution;

[0040] (2) The titanium alloy substrate is hydroxylated to form a hydroxylated substrate;

[0041] (3) The layer of self-assembled polyelectrolyte layer includes the following steps:

[0042](3.1) Put the hydroxylated substrate into the polycation electrolyte solution so asit, form a layer of polycation electrolyte layer, remove cleaning and dry;

[0043] (3.2) and then immersed in the polyanionic electrolyte solution to form a layer of polyanion electrolyte layer, remove cleaning and dry;

[0044] (3.3) Repeat step (3.1) and (3.2) in turn, form a multilayer polymer electrolyte layer having an interleaved N-layer polycation electrolyte layer and an N layer polymerionion electrolyte layer;

[0045] Complete the preparation of artificial joint...

Embodiment 1

[0056] 1 # Preparation of titanium alloy artificial joints with biological lubrication layers.

[0057] The aqueous 1 mg / ml of polydienyl dimethyl chloride solution, 1 mg / ml of polyacrylic acid solution, and the titanium alloy substrate was treated, and the time was 5 min, and the hydroxylated substrate was obtained; the hydroxylated substrate was immersed. After 5 min in an aqueous polythylene dimethyl ammonium chloride, washing and drying with deionized water, then immersed in aqueous polyacrylic acid aqueous solution of 5 min, removed with deionized water and blowing; in two polyelectrolytes In the solution, it is subjected to 5 times, and a multilayer polymer electrolyte layer having a 5-layer polymerization layer having a 3-layer polymerion-free layer is formed on the titanium alloy substrate. Made 1 # Titanium alloy artificial joint with biological lubrication layers.

Embodiment 2

[0059] 2 # Preparation of titanium alloy artificial joints with biological lubrication layers.

[0060] 2 mg / ml of polymethlamine aqueous solution, 2 mg / ml of polymethyl methacrylic acid solution, 2 mg / ml of polymethyl methacrylic acid solution; Treatment of a Piranha solution of the titanium alloy substrate, 80 ° C water bath, to obtain a hydroxylated substrate; extract the hydroxylated substrate in polyhydrate The aqueous solution of acrylamine was 60 min, and the deionized water was cleaned and dried, and then immersed in aqueous polymethyl methacrylic acid solution for 60 min, and the removed water was washed and blown; in two polyelectrolyte solutions, it was immersed 10 times, respectively. A multilayer polymer electrolyte layer having a 10-layer polymerization layer having a interlaced superimposed layer is formed on the titanium alloy substrate. Made 2 # Titanium alloy artificial joint with biological lubrication.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com