Molecular sieve core-mesoporous organosilicon hollow shell hierarchical porous composite material and preparation method thereof

A technology of mesoporous silicone and composite materials, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of unreported hollow core-shell hierarchical porous composite materials, and achieve high specific surface area. , the effect of a wide range of application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

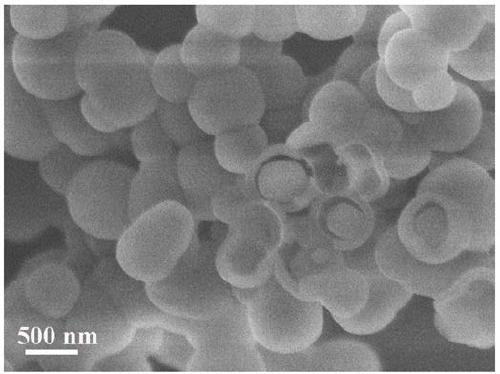

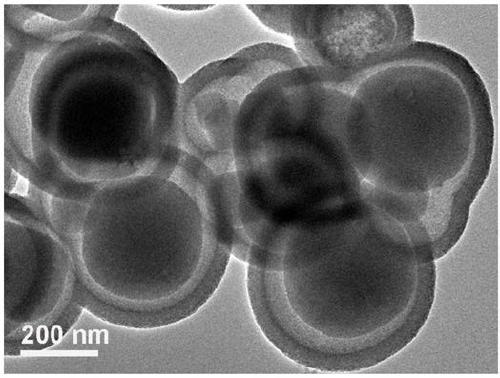

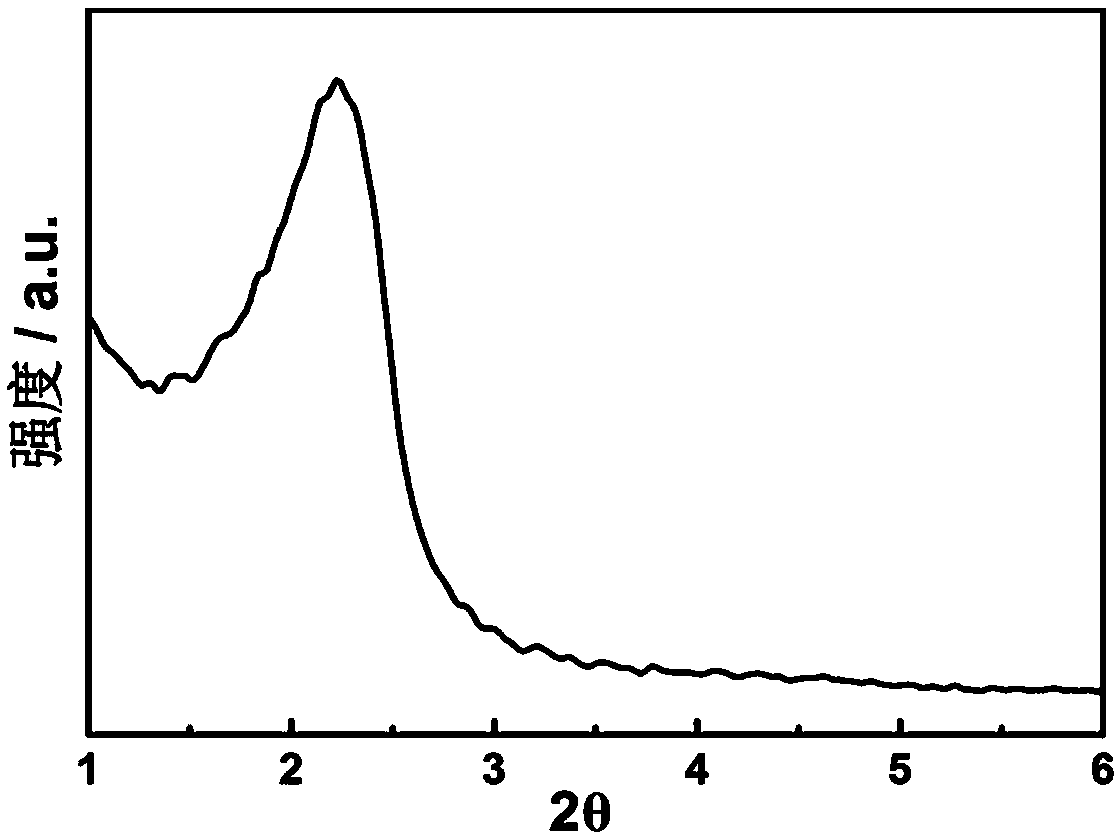

[0026] Step 1, uniformly disperse 80mg of type A molecular sieve nanoparticle material in a mixed system of 22mL of water and 11mL of ethanol, then add 0.25mL of ammonia water and stir magnetically at room temperature, then add 0.12g of cetyltrimethylammonium bromide and continue stirring 30min, then dropwise added 0.15mL tetraethyl orthosilicate, stirred and hydrolyzed for 6h, centrifuged (12000rpm, 3min), washed 4 times with deionized water and ethanol, dried at room temperature, in 50mL ethanol solution of ammonium nitrate (nitric acid The mass ratio of ammonium and ethanol is 0.25:80~0.4:80) to extract and remove the surfactant to obtain a type A molecular sieve-mesoporous silica core-shell composite white powder;

[0027] Step 2: Accurately weigh 80 mg of the white powder of the above-mentioned type A molecular sieve-mesoporous silica core-shell complex and add it to a mixture of 22 mL of water and 11 mL of ethanol, then add 2 mL of ammonia water and stir magnetically at r...

Embodiment 2

[0030] Step 1, uniformly disperse 80mg of type A molecular sieve nanoparticle material in a mixed system of 22mL of water and 11mL of ethanol, then add 0.25mL of ammonia water and stir magnetically at room temperature, then add 0.12g of cetyltrimethylammonium bromide and continue stirring 30min, then dropwise added 0.13mL tetraethyl orthosilicate, stirred and hydrolyzed for 6h, centrifuged (12000rpm, 3min), washed 4 times with deionized water and ethanol, dried at room temperature, in 40mL ethanol solution of ammonium nitrate (nitric acid The mass ratio of ammonium and ethanol is 0.25:80~0.4:80) to extract and remove the surfactant to obtain a type A molecular sieve-mesoporous silica core-shell composite white powder;

[0031]Step 2: Accurately weigh 80 mg of the white powder of the above-mentioned type A molecular sieve-mesoporous silica core-shell complex and add it to a mixture of 22 mL of water and 11 mL of ethanol, then add 2 mL of ammonia water and stir magnetically at ro...

Embodiment 3

[0034] Step 1, uniformly disperse 80mg of type A molecular sieve nanoparticle material in a mixed system of 22mL of water and 11mL of ethanol, then add 0.25mL of ammonia water and stir magnetically at room temperature, then add 0.12g of cetyltrimethylammonium bromide and continue stirring 30min, then dropwise added 0.15mL tetraethyl orthosilicate, stirred and hydrolyzed for 6h, centrifuged (12000rpm, 3min), washed 4 times with deionized water and ethanol, dried at room temperature, in 40mL ethanol solution of ammonium nitrate (nitric acid The mass ratio of ammonium and ethanol is 0.25:80~0.4:80) to extract and remove the surfactant to obtain a type A molecular sieve-mesoporous silica core-shell composite white powder;

[0035] Step 2: Accurately weigh 80 mg of the white powder of type A molecular sieve-mesoporous silica core-shell complex and add it to a mixture of 22 mL of water and 11 mL of ethanol, then add 2 mL of ammonia water and stir magnetically at room temperature, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com