Method for integrally treating malodorous gas by biofilter

A biofilter and malodorous gas technology, applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of increased operational difficulty and operating costs, long domestication time of indigenous microorganisms, and microbial growth to provide nutrition, etc., to achieve density Small size, increased cushioning, and strong water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

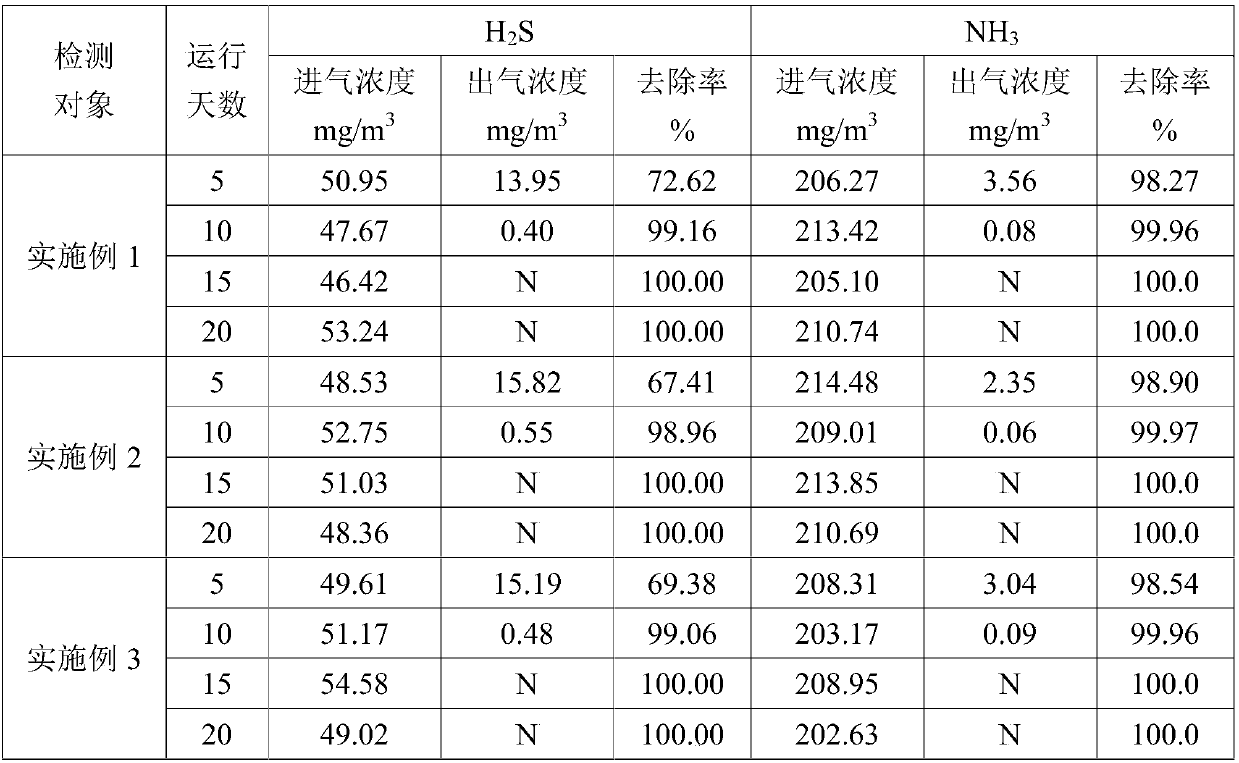

Embodiment 1

[0035] The method for adopting the biofilter integrated treatment of malodorous gas of the present embodiment comprises the following steps:

[0036] 1) After the third batch of Flammulina velutipes is harvested, the remaining Flammulina velutipes rods are crushed to a particle size of 5-10mm to obtain the chaff, and the chicken manure with a mass of 10% of the chaff and 12% of the chaff are added to the chaff. After the sludge is mixed, the water content is adjusted to 65%, composted and fermented to obtain decomposed fungus chaff;

[0037] Mix the raw materials according to the following mass percentages to make a composite filler: 38% volcanic rock, 11% activated carbon, 50% decomposed fungal chaff, and 1% limestone; adjust the water content of the composite filler to 60%; the bulk density of the composite filler is 557.1kg / m 3 ;

[0038] 2) firstly fill the porous plate inside the biological filter with gravel with a particle size of 10-20mm, and the filling height is 1...

Embodiment 2

[0042] The method for adopting the biofilter integrated treatment of malodorous gas of the present embodiment comprises the following steps:

[0043] 1) After the third batch of Flammulina velutipes is harvested, the remaining Flammulina velutipes rods are crushed to a particle size of 5-10mm to obtain the chaff, and the chicken manure with a mass of 9% of the chaff and 13% of the chaff are added to the chaff. After the sludge is mixed, the water content is adjusted to 65%, composted and fermented to obtain decomposed fungus chaff;

[0044] Mix the raw materials according to the following mass percentages to make a composite filler: 40% volcanic rock, 9.2% activated carbon, 50% decomposed fungus chaff, and 0.8% limestone; adjust the water content of the composite filler to 60%; the bulk density of the composite filler is 582.4kg / m 3 ;

[0045] 2) firstly fill the porous plate inside the biological filter with gravel with a particle size of 10-20mm, and the filling height is...

Embodiment 3

[0049] The method for adopting the biofilter integrated treatment of malodorous gas of the present embodiment comprises the following steps:

[0050] 1) After the third batch of Flammulina velutipes is harvested, the remaining Flammulina velutipes rods are crushed to a particle size of 5-10mm to obtain the chaff, and the chicken manure with a mass of 8% of the chaff mass and 15% of the chaff mass are added to the chaff. After the activated sludge is mixed, the water content is adjusted to 65%, composted and fermented to obtain decomposed fungus chaff;

[0051] Mix the raw materials according to the following mass percentages to make a composite filler: volcanic rock 39%, activated carbon 10.1%, decomposed fungus chaff 50%, limestone 0.9%; adjust the moisture content of the composite filler to 60%; the bulk density of the composite filler is 570.8kg / m 3 ;

[0052] 2) firstly fill the porous plate inside the biological filter with gravel with a particle size of 10-20mm, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Packing density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com