Preparation method of non-noble metal modified manganese oxide molecular sieve catalyst for catalytic combustion of toluene

A non-precious metal, catalytic combustion technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, combustion method, physical/chemical process catalyst, etc., can solve the problems of low ignition temperature, easy failure, high cost, etc., to achieve Good thermal stability, conducive to popularization and application, and the effect of reducing preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

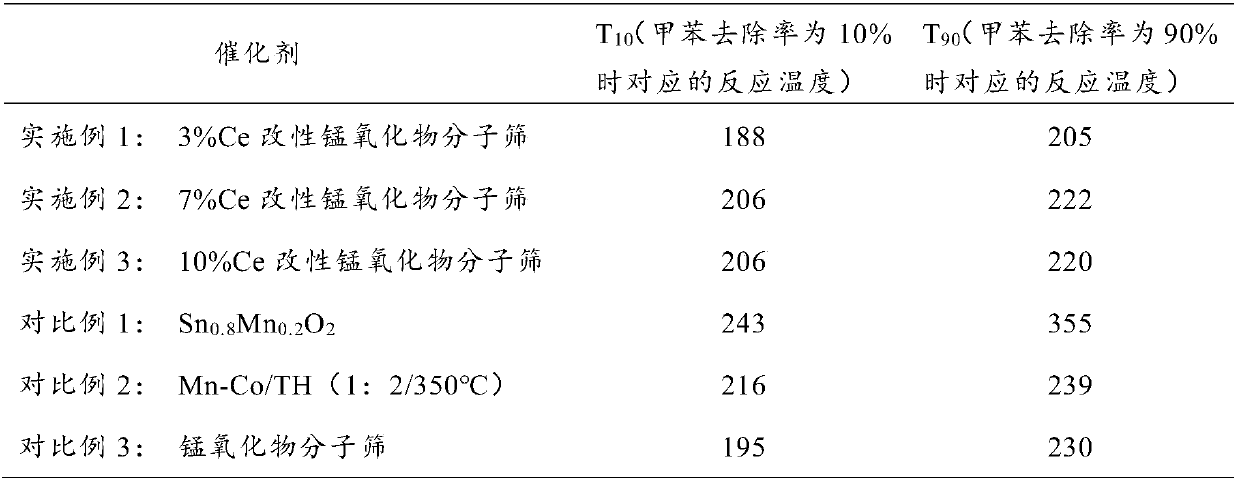

Examples

preparation example Construction

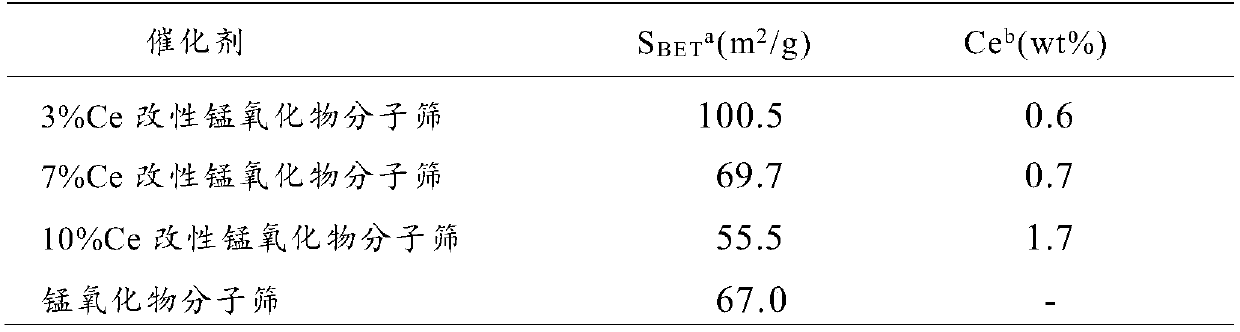

[0016] The first aspect of the present invention provides a method for preparing a non-noble metal modified manganese oxide molecular sieve catalyst that catalyzes combustion of toluene, the steps comprising:

[0017] S1. Weigh MnSO 4 ·H 2 O was dissolved in deionized water and HNO was added 3 get MnSO 4 ·H 2 O and HNO 3 mixed solution;

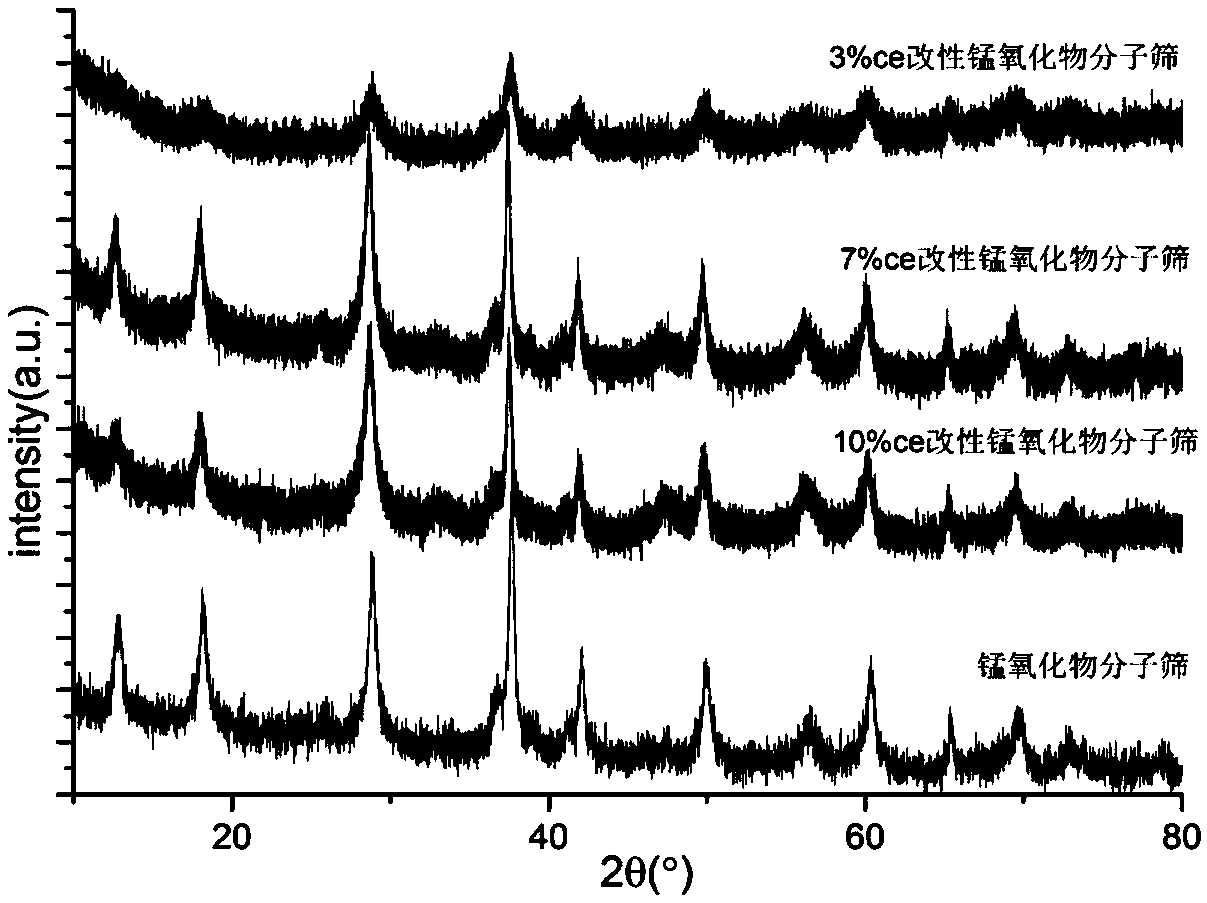

[0018] S2, the KMnO 4 Add to deionized water, stir to get KMnO 4 solution; the KMnO 4 The solution was added dropwise to the MnSO4 described in step S1 4 ·H 2 O and HNO 3 In the mixed solution, stir and reflux at 90-120°C for 22-26h. After the reaction, the solid obtained is washed, purified and dried with deionized water to obtain a dry solid product. It should be noted that the completely dissolved KMnO 4 The solution is dripped into the mixed solution prepared in step S1. This dripping sequence and the subsequent reflux process are the most critical steps of the present invention, which directly affect the formation of the mang...

Embodiment 1

[0033] This embodiment provides a method for preparing a non-noble metal modified manganese oxide molecular sieve catalyst that catalyzes combustion of toluene, the steps comprising:

[0034] Weigh 5.8g KMnO 4 Put it into a 250mL dry and clean beaker, add 80mL deionized water, and stir for 1 hour to obtain solution A. Weigh 8.8g MnSO 4 ·H 2 O, put it into a 250mL dry and clean Erlenmeyer flask, add 30mL deionized water, stir to make it fully dissolve, measure 3mLHNO 3 (analytical pure) add MnSO 4 solution to obtain solution B. Add the aforementioned A solution to the B solution drop by drop. The obtained mixed solution was placed in a 105° C. oil bath, stirred and refluxed for 25 hours. The solid product obtained by the reflux reaction was washed and purified with a sufficient amount of deionized water in a centrifuge at 4000 rpm, and centrifuged for 7 minutes each time, 7 times in total. The purified solid product was transferred into a dry and clean beaker, put into a...

Embodiment 2

[0041] This embodiment provides a method for preparing a non-noble metal modified manganese oxide molecular sieve catalyst that catalyzes combustion of toluene, the steps comprising:

[0042] Weigh 11.6g KMnO 4 Put it into a 500mL dry and clean beaker, add 160mL deionized water, and stir for 1 hour to obtain solution A. Weigh 17.6g MnSO 4 ·H 2 O, put it into a 500mL dry and clean Erlenmeyer flask, add 60mL deionized water, stir to make it fully dissolve, measure 6mLHNO 3 (analytical pure) into MnSO 4 solution to obtain solution B. Add the aforementioned A solution to the B solution drop by drop. The obtained mixed solution was placed in an oil bath at 102° C., stirred and refluxed for 26 hours. The solid product obtained by the reflux reaction was washed and purified 5 times in a centrifuge at 5000 rpm with sufficient deionized water. The purified solid product was transferred into a dry and clean beaker, put into a drying oven and dried at a temperature of 110° C. for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com