Underwater oleophobic structural color film, and preparation method and application thereof

A structural color and thin film technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of complex structure manufacturing, and achieve the effect of improving strength, making up for poor heat resistance, and enhancing underwater oleophobic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the underwater oleophobic structural color film of the present invention comprises the following steps:

[0034] 1) Preparation of modified PS colloidal microsphere emulsion: Purification of styrene, adding the purified styrene, α-methacrylic acid and deionized water into a three-neck round bottom flask, magnetically stirring for more than 30min to make the solution evenly mixed, and then Put it in an oil bath at 75-90°C, stir magnetically for 30-60min, inject potassium persulfate solution, and react under constant temperature to obtain a modified PS colloidal microsphere emulsion; a mixture of styrene, α-methacrylic acid and deionized water The ratio is: (14-28)mL: (1-2)mL: (180-360)mL.

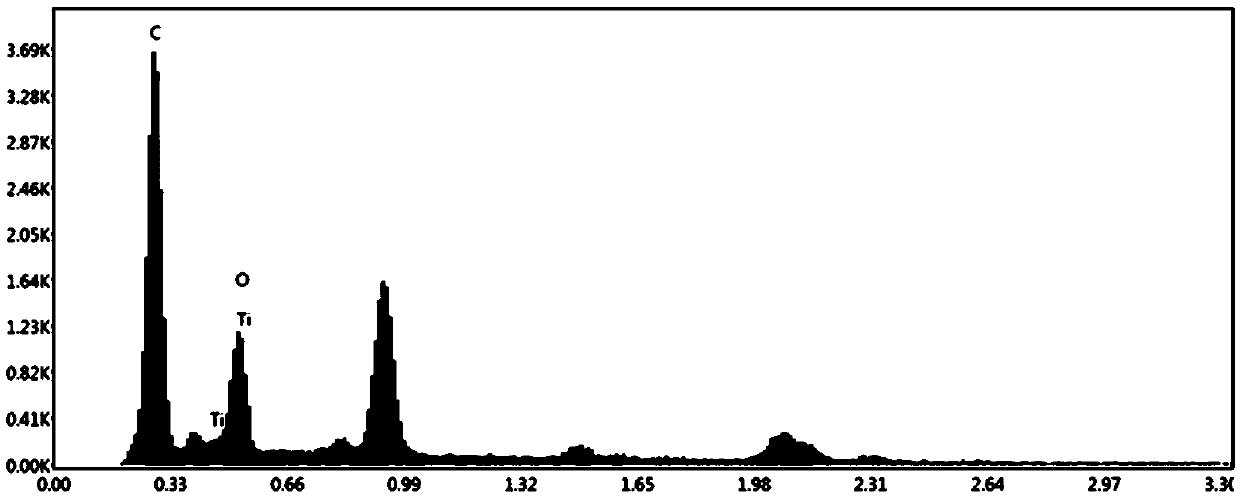

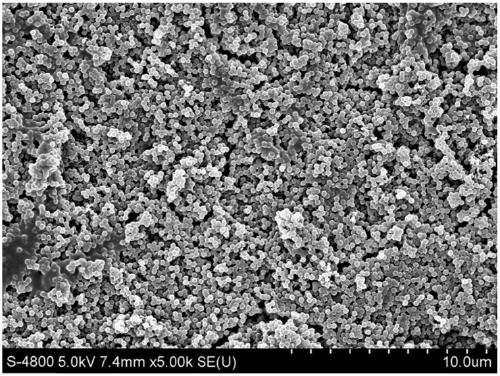

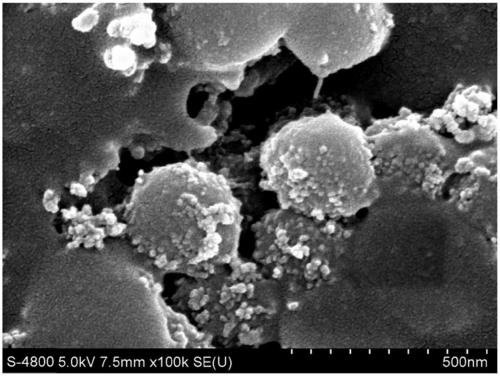

[0035] 2) Encapsulated TiO 2Shell structure: the obtained modified PS colloidal microsphere emulsion is dispersed in the mixed solution of ethanol and acetonitrile, which is recorded as liquid A; butyl titanate (TBOT) is dissolved in the mixed liquid of etha...

Embodiment 1

[0041] A preparation method of an underwater oleophobic structural color film, comprising the following steps:

[0042] 1) Raw material pretreatment: Purify styrene, wash twice with 10% sodium hydroxide solution, then wash more than three times with ultrapure water until the solution is neutral to remove polymerization inhibitor, add a small amount of solid anhydrous chlorination Calcium, remove the water, seal and store in the refrigerator for later use.

[0043] 2) Preparation of modified PS colloidal microsphere emulsion: Purification of styrene, take 14mL of purified styrene solution, 1mL of α-methacrylic acid, and 180mL of deionized water in a three-necked round-bottomed flask, stir magnetically for 30min, and mix the solution , placed in an oil bath at 80°C, magnetically stirred for 30min, injected with a concentration of 1.7g / mL, 20mL of potassium persulfate solution, and reacted at a constant temperature of 75°C for 7h to obtain a modified PS colloidal microsphere emul...

Embodiment 2

[0047] A preparation method of an underwater oleophobic structural color film, comprising the following steps:

[0048] 1) Raw material pretreatment: Purify styrene, wash twice with 10% sodium hydroxide solution, then wash more than three times with ultrapure water until the solution is neutral to remove polymerization inhibitor, add a small amount of solid anhydrous chlorination Calcium, remove the water, seal and store in the refrigerator for later use.

[0049] 2) Preparation of modified PS colloidal microsphere emulsion: Purification of styrene, take 20mL of purified styrene solution, 1.5mL of α-methacrylic acid, and 240mL of deionized water in a three-necked round-bottomed flask, and magnetically stir for 30min to make the solution Mix, put in an oil bath at 80°C, stir magnetically for 30min, inject 20mL of potassium persulfate solution at a concentration of 1.7g / mL, react at a constant temperature of 80°C for 8h, and obtain a modified PS colloidal microsphere emulsion; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com