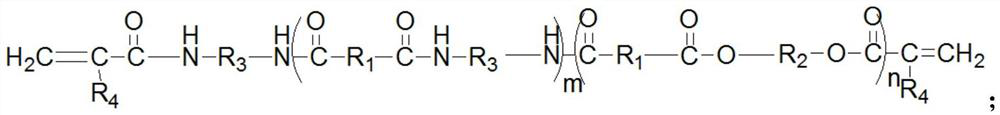

Photosensitive resin of amine-modified polyester acrylate and synthesis method thereof

A polyester acrylate, photosensitive resin technology, applied in polyester coatings, coatings, etc., can solve the problems of low viscosity, high solid shrinkage, poor gloss and wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

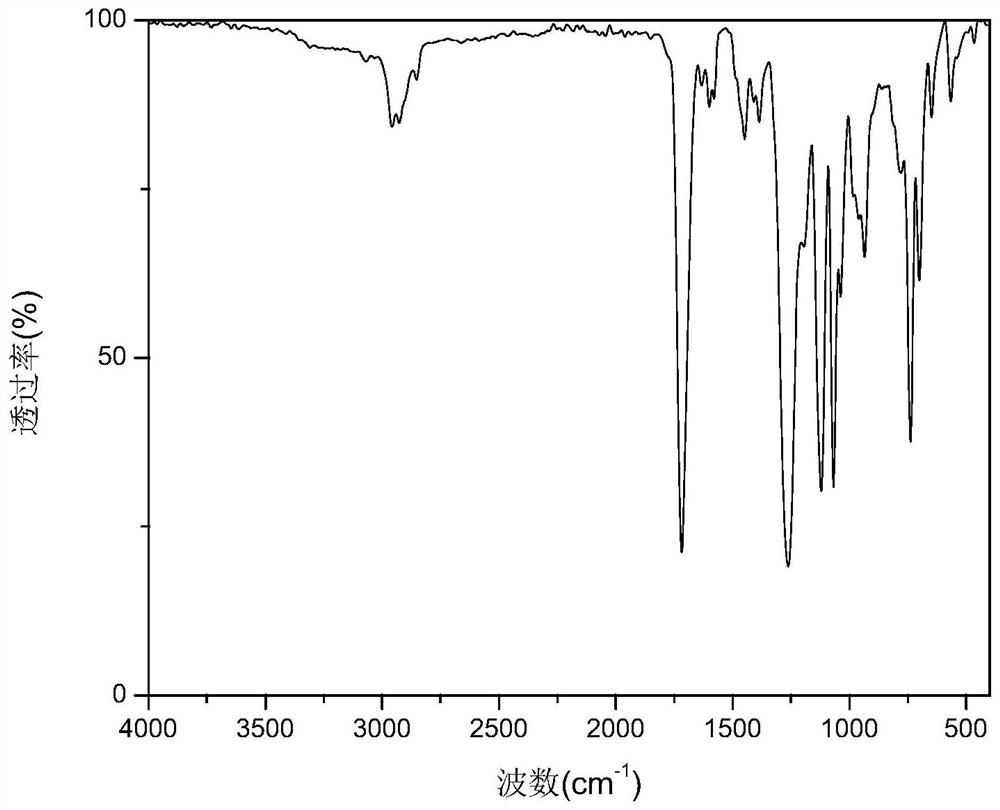

Embodiment 1

[0037] (1) take by weighing 29.4g (0.3mol) maleic anhydride and toluene 6.09g of reactant gross mass 10wt% in the there-necked flask of 250mL, oil bath, be heated to 60 ℃ and maleic anhydride is completely dissolved in toluene, in Under the protection of nitrogen, add 29.7g (0.33mol) of 1,4-butanediol, 1.8g (0.03mol) of ethylenediamine and 0.5wt% of the total mass of reactants as a catalyst, 0.3045g of dibutyltin dilaurate, and react at 180°C 4h, when the acid value in the system is stable, the device is added into the water separator to divide the water to increase the reaction degree. When the water separator has no reflux, add toluene as 5wt% of the total mass of the reactants to be 3.045g. When the acid value is less than or equal to 5mgKOH / g, when the amount of xylene distilled out in vacuum is consistent with the amount added, the reaction stops and a hydroxyl-terminated polyester is obtained.

[0038] (2) Weigh 8.64g (0.12mol) of acrylic acid, 0.2592g of monomer mass 3...

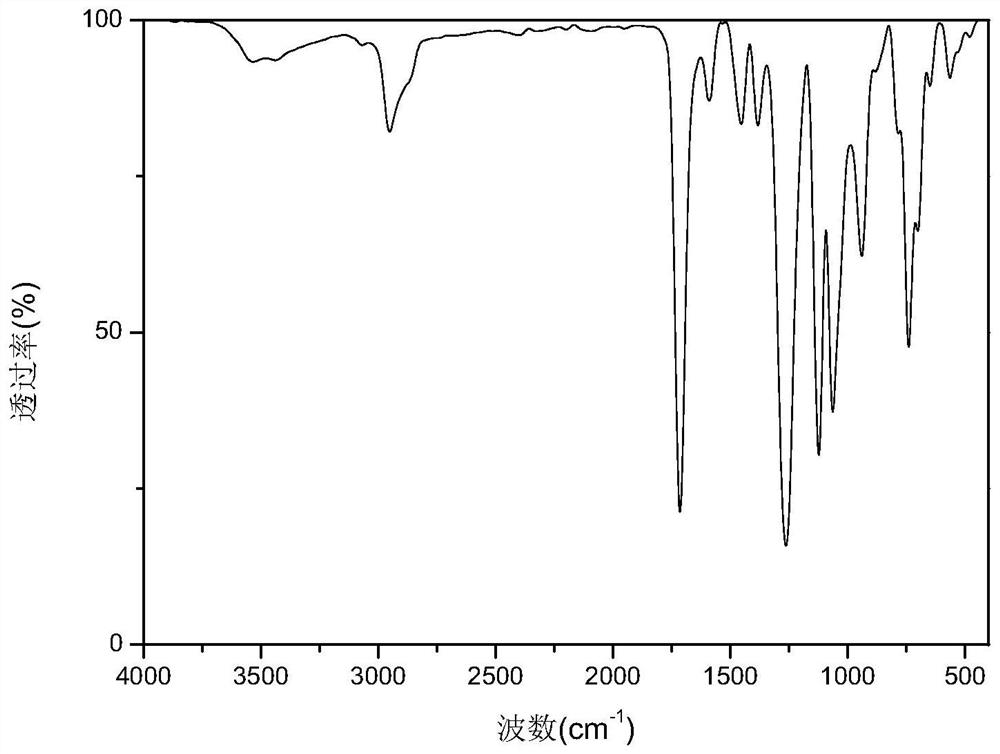

Embodiment 2

[0043] (1) Weigh 29.6g (0.2mol) of phthalic anhydride and 5.12g of xylene with a total mass of reactants of 10wt% in a 100mL three-necked flask, heat it to 130°C in an oil bath to completely dissolve phthalic anhydride In xylene, under the protection of nitrogen, add 18g (0.2mol) of 1,4-butanediol, 2.4g (0.4mol) of ethylenediamine and 0.5wt% catalyst dibutyltin dilaurate of the total mass of reactants 0.256g , reacted at 180°C for 6h, when the acid value in the system was stable, the device added a water separator to divide water to increase the reaction degree, when the water separator had no reflux, add xylene as 5wt% of the total mass of the reactants to be 2.56g , when the acid value is less than or equal to 5mg KOH / g, when the amount of xylene distilled out in vacuum is consistent with the added amount, the reaction is stopped to obtain a hydroxyl-terminated polyester.

[0044] (2) Take by weighing 5.76g (0.08mol) acrylic acid, monomer quality 3wt% p-toluenesulfonic acid ...

Embodiment 3

[0049] (1) Weigh 29.4g (0.3mol) of maleic anhydride and 6.09g of cyclohexane with a total reactant mass of 10wt% in a 250mL three-necked flask, heat it to 60°C in an oil bath to completely dissolve maleic anhydride in cyclohexane In alkanes, under the protection of nitrogen, add 29.7g (0.33mol) of 1,4-butanediol, 1.8g (0.03mol) of ethylenediamine, and 0.3wt% of the total mass of reactants. Catalyst phosphoric acid 0.1827g, react at 160 ° C 6h, when the acid value in the system is stable, the device is added into a water separator to divide water, so that the reaction degree is improved. When the water separator has no reflux, add cyclohexane as 5wt% of the total mass of the reactant to be 3.045g, when the acid value When ≤5mgKOH / g, when the amount of cyclohexane distilled out in vacuum is consistent with the added amount, the reaction stops and a hydroxyl-terminated polyester is obtained.

[0050] (2) Weigh 8.64g (0.12mol) of acrylic acid, 0.432g of monomer mass 5wt% butyl tit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com