A kind of pretreatment method of low-grade uranium ore

A low-grade, pretreatment technology, applied in the field of uranium pretreatment, can solve the problems of long time, high energy consumption, aggravation of secondary pollution and damage to the original ecological environment, and achieve the effect of low cost and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

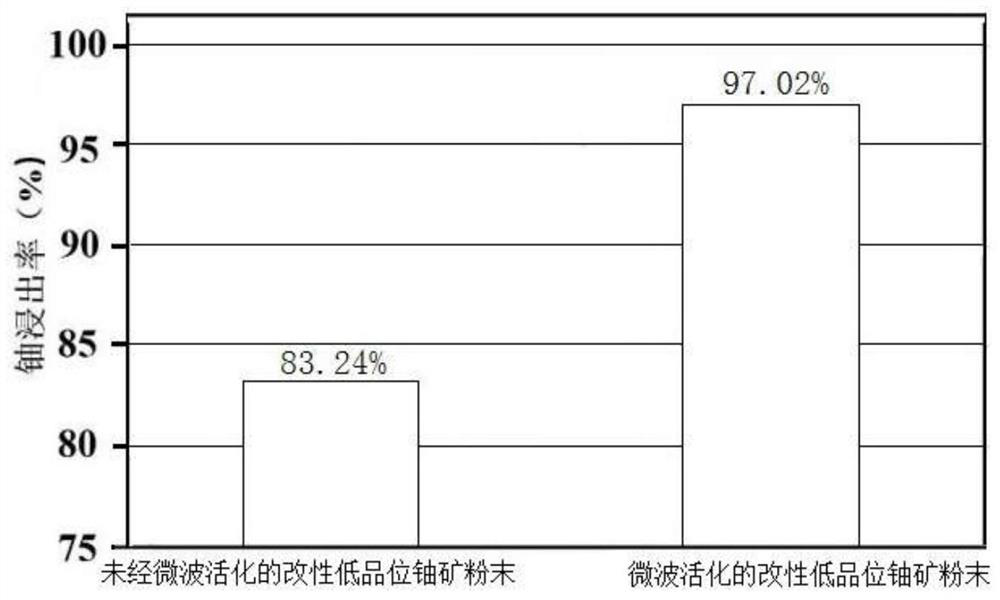

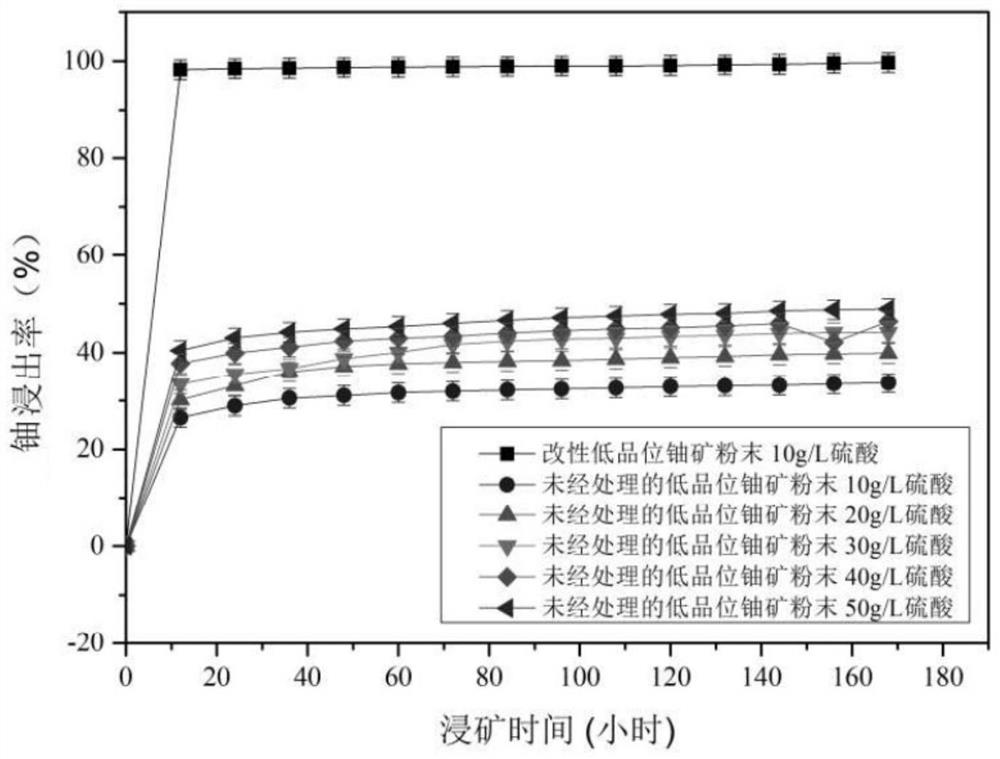

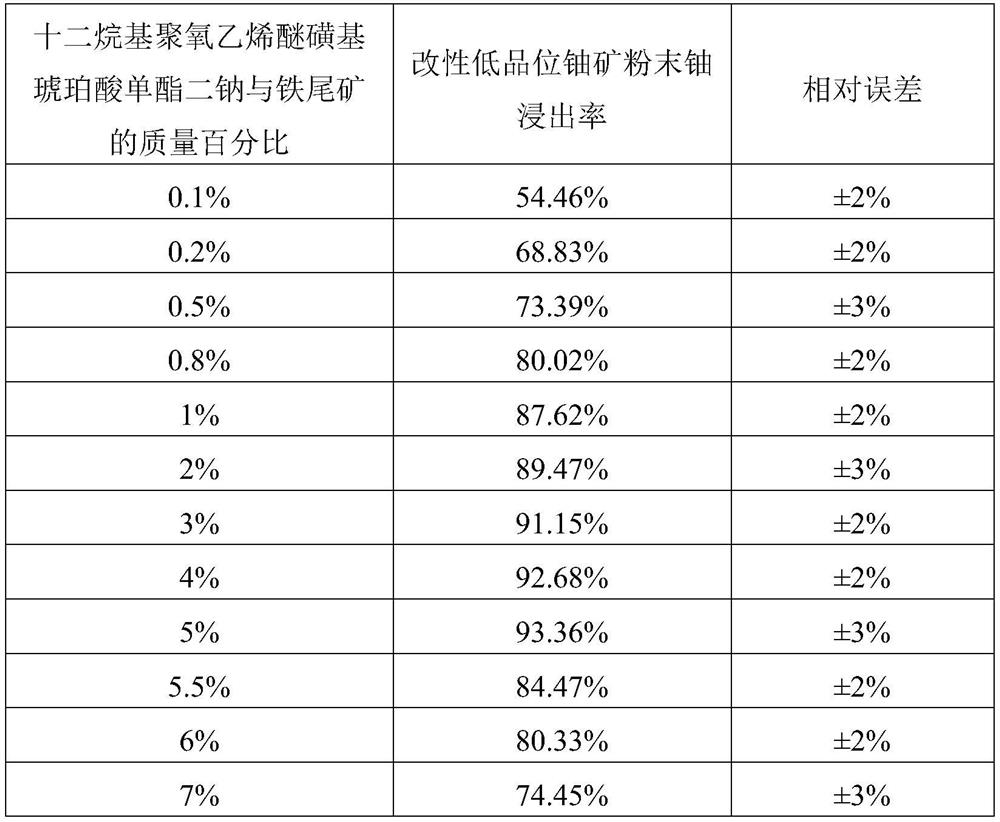

[0021] Effect of the mass percentage of disodium lauryl polyoxyethylene ether sulfosuccinate and iron tailings on the leaching rate of uranium from modified low-grade uranium ore powder:

[0022] Weigh iron tailings, lauryl polyoxyethylene ether sulfosuccinic acid monoester disodium, manganese dioxide respectively, mix and grind for 2 hours, and pass through a 100 mesh sieve to obtain iron tailings grinding powder, wherein, twelve The mass percentages of disodium alkylpolyoxyethylene ether sulfosuccinate monoester and iron tailings are 0.1%, 0.2%, 0.5%, 0.8%, 1%, 2%, 3%, 4%, 5%, 5.5%, 6%, 7%; the mass percentage of manganese dioxide and iron tailings is 1%; the iron tailings ground powder is mixed with water, stirred for 1 hour, dried at 100°C to constant weight, and ground to obtain Active iron tailings oxidant: according to the mass percentage of active iron tailings oxidant and uranium tailings 2%, weigh uranium tailings and active iron tailings oxidant respectively, mix an...

Embodiment 2

[0029] The effect of the mass percentage of manganese dioxide and iron tailings on the leaching rate of modified low-grade uranium ore powder:

[0030] Weigh iron tailings, lauryl polyoxyethylene ether sulfosuccinate disodium, and manganese dioxide respectively, mix and grind for 4 hours, and pass through a 200-mesh sieve to obtain iron tailings grinding powder, wherein, twelve The mass percentage of alkyl polyoxyethylene ether monosodium sulfosuccinate and iron tailings is 5%, and the mass percentages of manganese dioxide and iron tailings are 0.1%, 0.2%, 0.5%, 0.8%, and 1% respectively. %, 2%, 3%, 4%, 5%, 5.5%, 6%, 7%; mix iron tailings grinding powder with water, stir for 2 hours, dry at 110°C until constant weight, and grind to obtain Active iron tailings oxidant: according to the mass percentage of active iron tailings oxidant and uranium tailings 4%, weigh uranium tailings and active iron tailings oxidant respectively, mix and grind for 4 hours, pass through a 200 mesh s...

Embodiment 3

[0035] Effect of active iron tailings oxidant and uranium tailings mass percentage on leaching rate of modified low-grade uranium ore powder:

[0036] Weigh the iron tailings, disodium lauryl polyoxyethylene ether sulfosuccinate, and manganese dioxide respectively, mix and grind for 6 hours, and pass through a 300-mesh sieve to obtain the iron tailings grinding powder, wherein, twelve The mass percent of disodium alkyl polyoxyethylene ether sulfosuccinate monoester and iron tailings is 5%, and the mass percent of manganese dioxide and iron tailings is 5%; the iron tailings ground powder is mixed with water, stirred 3 hours, dry to constant weight at 120°C, grind to obtain active iron tailings oxidant; according to the mass percentage of active iron tailings oxidant and uranium tailings: 0.2%, 0.6%, 1%, 1.4%, 1.8%, 2 %, 3%, 4%, 5%, 6%, 7%, 8%, 9.5%, 9%, and 10%, respectively weigh uranium tailings and active iron tailings oxidant, mix and grind for 6 hours, pass through 300 mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com