Nickel-based titanium nitride metal ceramic coating material and preparation method and application thereof

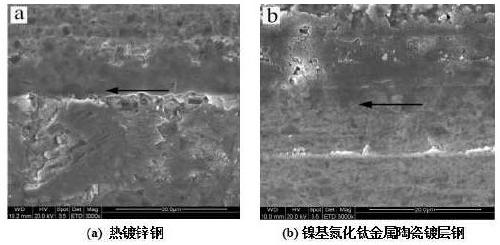

A metal-ceramic coating and ceramic coating technology are applied in the field of nickel-based titanium nitride metal-ceramic coating materials and their preparation, which can solve problems such as poor corrosion resistance of coatings, achieve strong corrosion resistance, increase service life, High bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A nickel-based titanium nitride cermet coating material comprises the following components in mass percentage: 75% of titanium nitride, 20% of nickel, and the rest is high-purity graphite powder with a particle size of 20 μm.

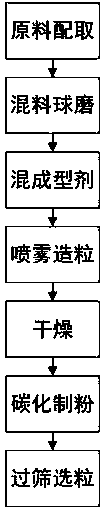

[0060] The preparation method of the above-mentioned nickel-based titanium nitride cermet coating material comprises the following steps:

[0061] S1. Mixing ball mill: Add the mixed powder of TiN powder, nickel powder and high-purity graphite powder into the planetary ball mill with a hard alloy inner layer embedded inside, add 500g of absolute ethanol to every 1000g of mixed powder, the ratio 8:1, the rotating speed is 260r / min, and the grinding time is 60h;

[0062] S2. Mixing agent: Prepare 5wt.% polyethylene glycol solution at a temperature of 90°C. After the ball milling is completed, mix the prepared polyethylene glycol solution into the mixture liquid, then roll the ball mill to mix evenly, and mix in 5wt. The quality of % polyethylene g...

Embodiment 2

[0067] A nickel-based titanium nitride cermet coating material comprises the following components in mass percentage: 85% of titanium nitride, 12% of nickel, and the rest is high-purity graphite powder with a particle size of 20 μm.

[0068] The preparation method of the above-mentioned nickel-based titanium nitride cermet coating material comprises the following steps:

[0069] S1. Mixing ball mill: Add the mixed powder of TiN powder, nickel powder and high-purity graphite powder into the planetary ball mill with a hard alloy inner layer embedded inside, add 500g of absolute ethanol to every 1000g of mixed powder, the ratio 8:1, the rotating speed is 260r / min, and the grinding time is 60h;

[0070] S2. Mixing agent: Prepare 4wt.% polyethylene glycol solution at a temperature of 90°C. After the ball milling is completed, mix the prepared polyethylene glycol solution into the mixture liquid, and then roll the ball mill to mix evenly. The mixed 4wt. The quality of % polyethylen...

Embodiment 3

[0075] A nickel-based titanium nitride cermet coating material comprises the following components in mass percent: 65% of titanium nitride, 28% of nickel, and the rest is high-purity graphite powder with a particle size of 20 μm.

[0076] The preparation method of the above-mentioned nickel-based titanium nitride cermet coating material comprises the following steps:

[0077] S1. Mixing ball mill: Add the mixed powder of TiN powder, nickel powder and high-purity graphite powder into the planetary ball mill with a hard alloy inner layer embedded inside, add 500g of absolute ethanol to every 1000g of mixed powder, the ratio 8:1, the rotating speed is 260r / min, and the grinding time is 60h;

[0078] S2. Mixing agent: Prepare 5wt.% polyethylene glycol solution at a temperature of 90°C. After the ball milling is completed, mix the prepared polyethylene glycol solution into the mixture liquid, then roll the ball mill to mix evenly, and mix in 5wt. The quality of % polyethylene glyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com