Pretreatment method of improving surface oxygen permeation capability of TC11 titanium alloy

A TC11, titanium alloy technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the influence of the mechanical properties of the matrix, the deterioration of the surface quality of the parts, the surface hardness of the oxygen permeation layer and the insufficient depth of the oxygen permeation layer. and other problems, to achieve the effect of increasing the surface hardness and the depth of the oxygen permeability layer, increasing the degree of hardening, and improving the oxygen permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A pretreatment method for improving the oxygen permeation ability of the surface of TC11 titanium alloy is carried out according to the following steps:

[0032] (1) Inspection: process inspection of incoming parts;

[0033] (2) Cleaning: Clean up the parts with acetone and dry them;

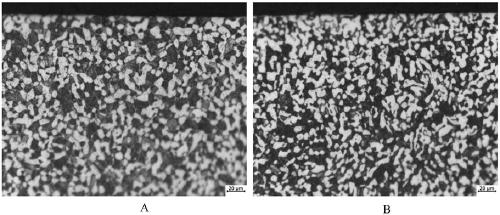

[0034] (3) Vacuum pretreatment: Before heating, pump the pressure in the vacuum chamber to below 0.067Pa, 950°C / 60min, fill with 0.4MPa argon gas after heat preservation and cool down to below 80°C, and release from the furnace; Comparing the pretreated sample with the unpretreated sample, it was found that the α-phase content of the near-surface structure of the pretreated part was 50.9%, which was significantly higher than that of the unpretreated part (40.3 %)(See figure 1 ).

[0035] (4) Oxygen infiltration: use the corundum sand embedding method for oxygen infiltration, the oxygen infiltration process is: heating to 800 ° C for 10 hours, air cooling;

[0036] (5) Secondary anneal...

Embodiment 2

[0039] A pretreatment method for improving the oxygen permeation ability of the surface of TC11 titanium alloy is carried out according to the following steps:

[0040] (1) Inspection: process inspection of incoming parts;

[0041] (2) Cleaning: Clean up the parts with acetone and dry them;

[0042] (3) Vacuum pretreatment: Before heating, pump the pressure in the vacuum chamber to below 0.067Pa, 950°C / 65min, fill with 0.2MPa argon to cool;

[0043] (4) Machining: The machining margin of the oxygen permeated surface is controlled at no more than 0.3mm;

[0044] (5) Oxygen permeation: Oxygen permeation using corundum sand embedding method, oxygen permeation process: 800°C / 10h, air cooling;

[0045] (6) Secondary annealing: heat preservation at 530°C for 6h, air cooling;

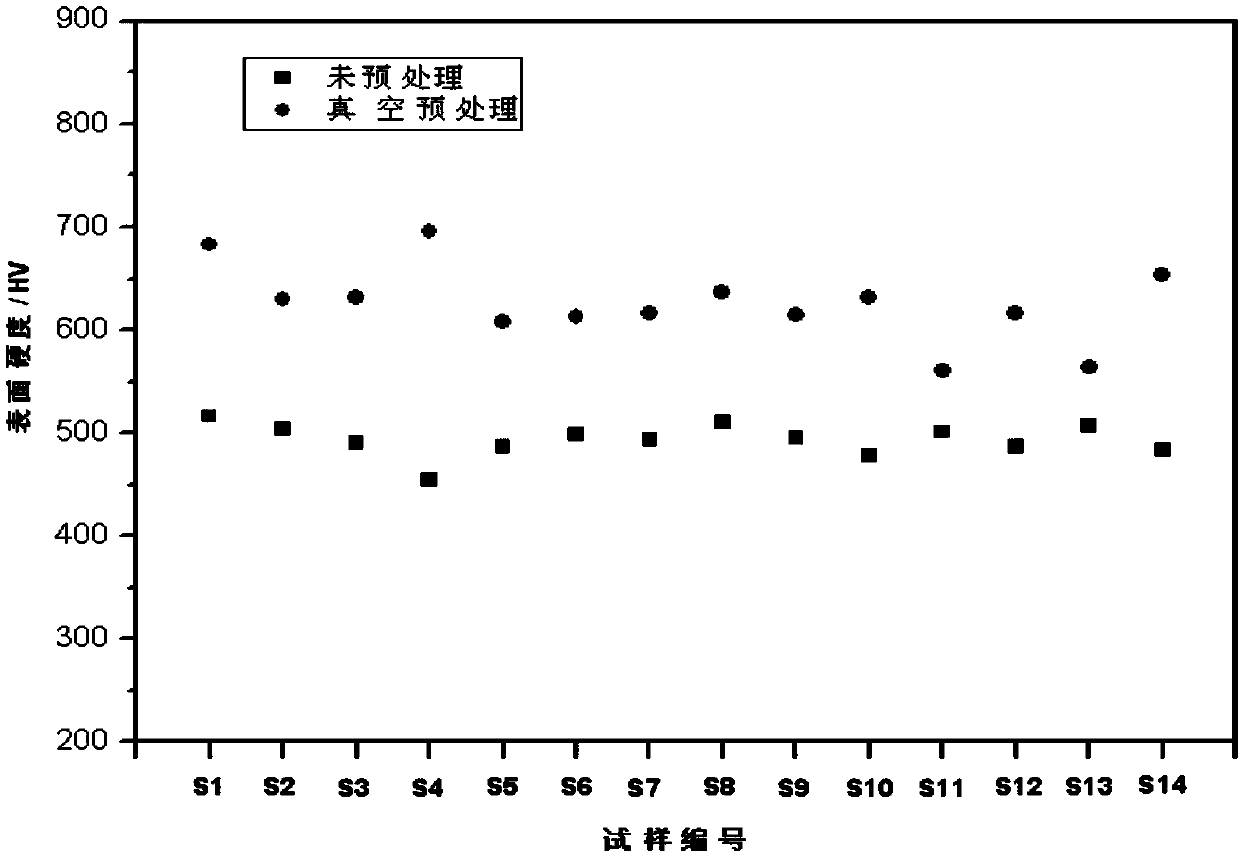

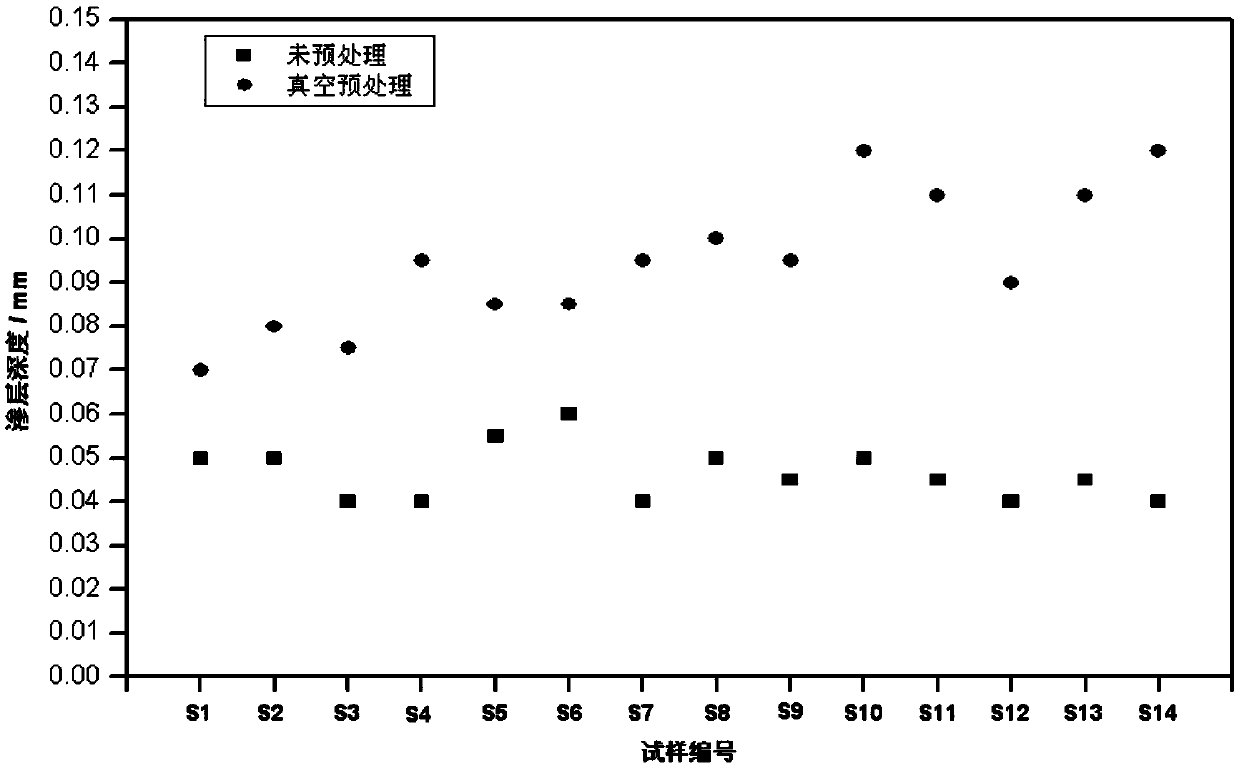

[0046] (7) Inspection: use a microhardness tester to inspect the surface microhardness and hardening depth of the α-hardened layer. The surface hardness of the parts treated with oxygen is 690kg / mm 2 , Th...

Embodiment 3

[0048] A pretreatment method for improving the oxygen permeation ability of the surface of TC11 titanium alloy is carried out according to the following steps:

[0049] (1) Inspection: process inspection of incoming parts;

[0050] (2) Cleaning: Clean up the parts with acetone and dry them;

[0051] (3) Vacuum pretreatment: Before heating, the pressure in the vacuum chamber is pumped to below 0.067Pa, 950°C / 70min, filled with 0.3MPa argon to cool;

[0052](4) Machining: The machining margin of the oxygen permeated surface is controlled at no more than 0.5mm;

[0053] (5) Oxygen permeation: Oxygen permeation using corundum sand embedding method, oxygen permeation process: 800°C / 10h, air cooling;

[0054] (6) Secondary annealing: heat preservation at 530°C for 6h, air cooling;

[0055] (7) Inspection: use a microhardness tester to inspect the surface microhardness and hardening depth of the α-hardened layer. The surface hardness of the parts treated with oxygen is 630kg / mm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com