Efficient Ni-S-B hydrogen evolution electrode and preparation method and application thereof

A hydrogen evolution electrode, ni-s-b technology, applied in the field of electrocatalytic hydrogen evolution, can solve the problems of pollution, easy generation of impurities, low coating strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

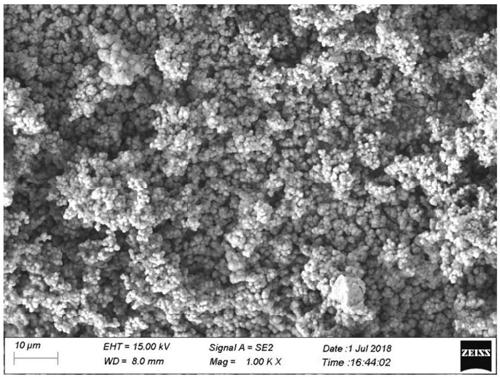

Image

Examples

preparation example Construction

[0029] The present invention also provides a kind of preparation method of efficient Ni-S-B hydrogen evolution electrode, comprises the following steps:

[0030] (1) provide electroplating aqueous solution, described electroplating aqueous solution comprises the component of following concentration: nickel source 80~160g / L, thiourea 80~130g / L, boron source 10~45g / L, complexing agent 60~100g / L , conductive agent 20-60g / L, saccharin 0.5-5.0g / L, sulfosalicylic acid 5-30g / L;

[0031] (2) Using the nickel substrate as the cathode and the anode, the distance between the cathode and the anode being 0.5-3.0 cm, performing electroplating with the electroplating aqueous solution obtained in the step (1) to obtain a Ni-S-B hydrogen evolution electrode.

[0032] Preferably, during the electroplating process in the step (2), the temperature of the electroplating aqueous solution is 25-65° C., and the electroplating time is 40-100 min.

[0033] Preferably, the current density of electropla...

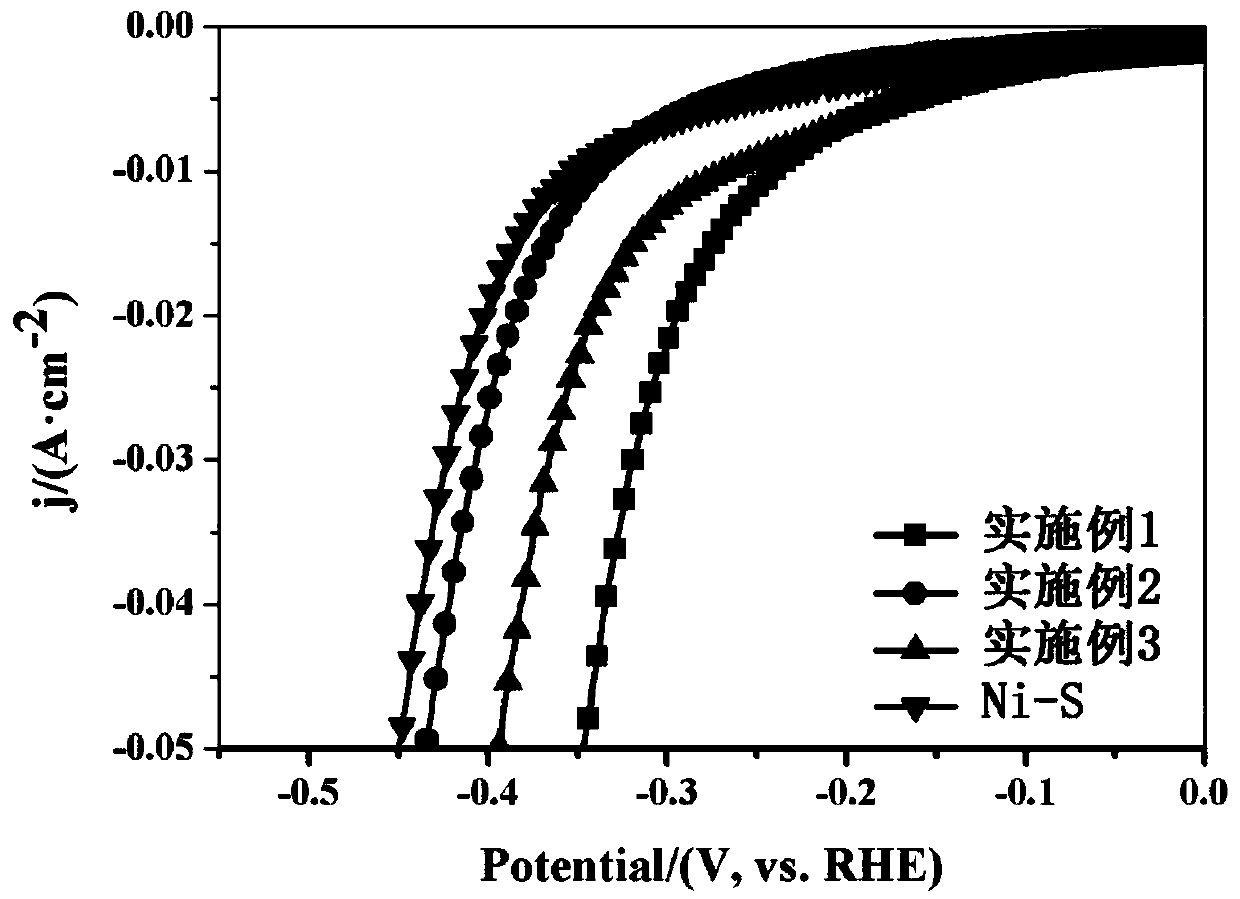

Embodiment 1

[0053] (1) Pretreatment of Ni matrix

[0054] First, the Ni sheet is mechanically polished to remove the oxide on the surface to make it metallic luster, and then cleaned with deionized water; then ultrasonically oscillated in lye and absolute ethanol for 20 minutes for chemical degreasing, wherein the lye is 15g / LNaOH, 60g / L Na 3 PO 4 12H 2 O, 25g / L Na 2 CO 3 and 15g / L Na 2 SiO 3 Then rinse with deionized water, boil and etch in 20% hydrochloric acid for 5 minutes, rinse with deionized water, dry naturally, and immerse in absolute ethanol solution for later use.

[0055] (2) Preparation of Ni-S-B hydrogen evolution electrode by electrodeposition

[0056] A double-anode and single-cathode system is adopted, and the Ni substrate treated in step (1) is used as the cathode and the anode. Composition of Ni-S-B plating solution: 140g / L NiSO 4 ·6H 2 O, 100g / L Thiourea, 40g / L Borax, 70g / L Na 3 C 6 h 5 o 7 2H 2 O, 20g / L NaCl, 1.5g / L saccharin, 5g / L sulfosalicylic acid,...

Embodiment 2

[0060] Step (1) is the same as step (1) in Example 1.

[0061] (2) Preparation of Ni-S-B hydrogen evolution electrode by electrodeposition

[0062] A dual-anode and single-cathode system is adopted, and the nickel sheet treated in step (1) is used as the cathode and the anode. Composition of Ni-S-B plating solution: 120g / L NiSO 4 ·6H 2 O, 80g / L thiourea, 30g / L borax, 80g / L Na 3 C 6 h 5 o 7 2H 2 O, 20g / L NaCl, 1.5g / L saccharin, 5g / L sulfosalicylic acid, the pH value of the plating solution is 3, the temperature of the plating solution is 50°C; the current density is 2A / dm 2 , The electrodeposition time is 70min. Rinse with deionized water after electroplating to remove residual plating solution, and dry naturally to prepare Ni-S-B hydrogen evolution electrode. The electrode composition was tested by an energy spectrometer, and the electrode composition was Ni: 70wt.%; S: 25wt.%; B: 5wt.%. The thickness of the electrodes was 20 μm. Step (3) is the same as step (3) in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com