Method for preparing chemical bath of tin antimony sulfur film

A technology of chemical bath and thin film, which is applied in the field of chemical bath preparation of tin-antimony-sulfur thin film, can solve the problems of high equipment cost and increased material preparation cost, and achieve low production cost, environmental compatibility and great process flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A chemical bath preparation method for a tin-antimony-sulfur thin film, comprising the steps of:

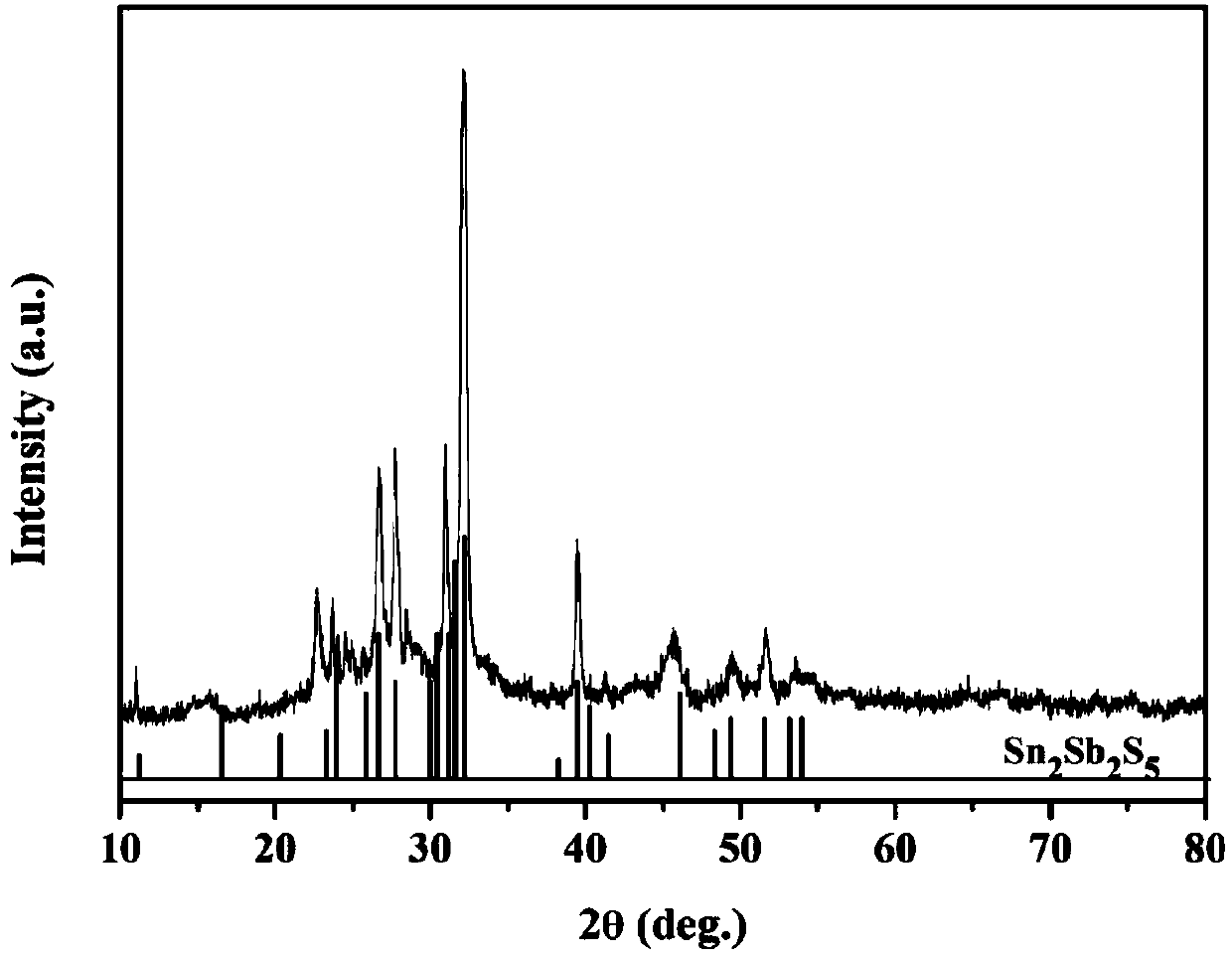

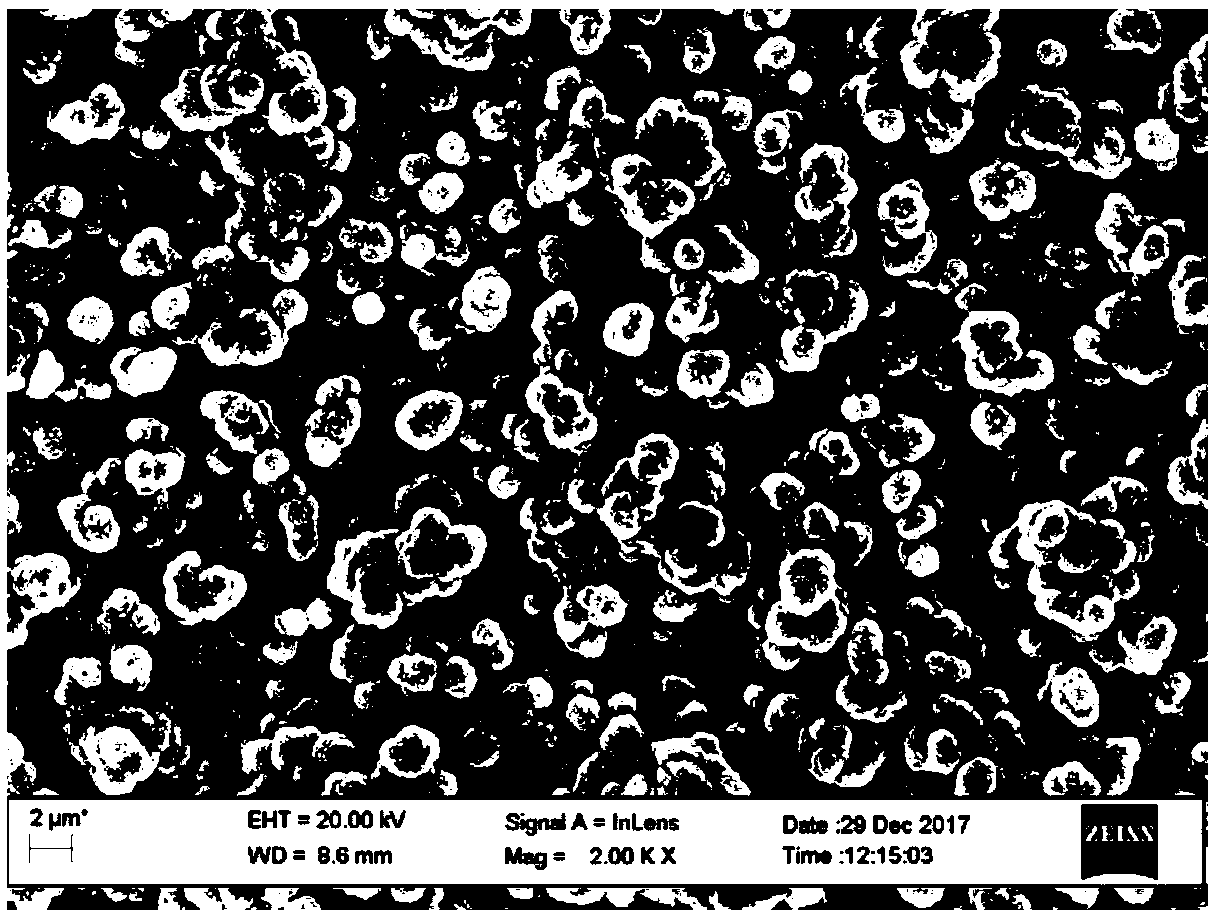

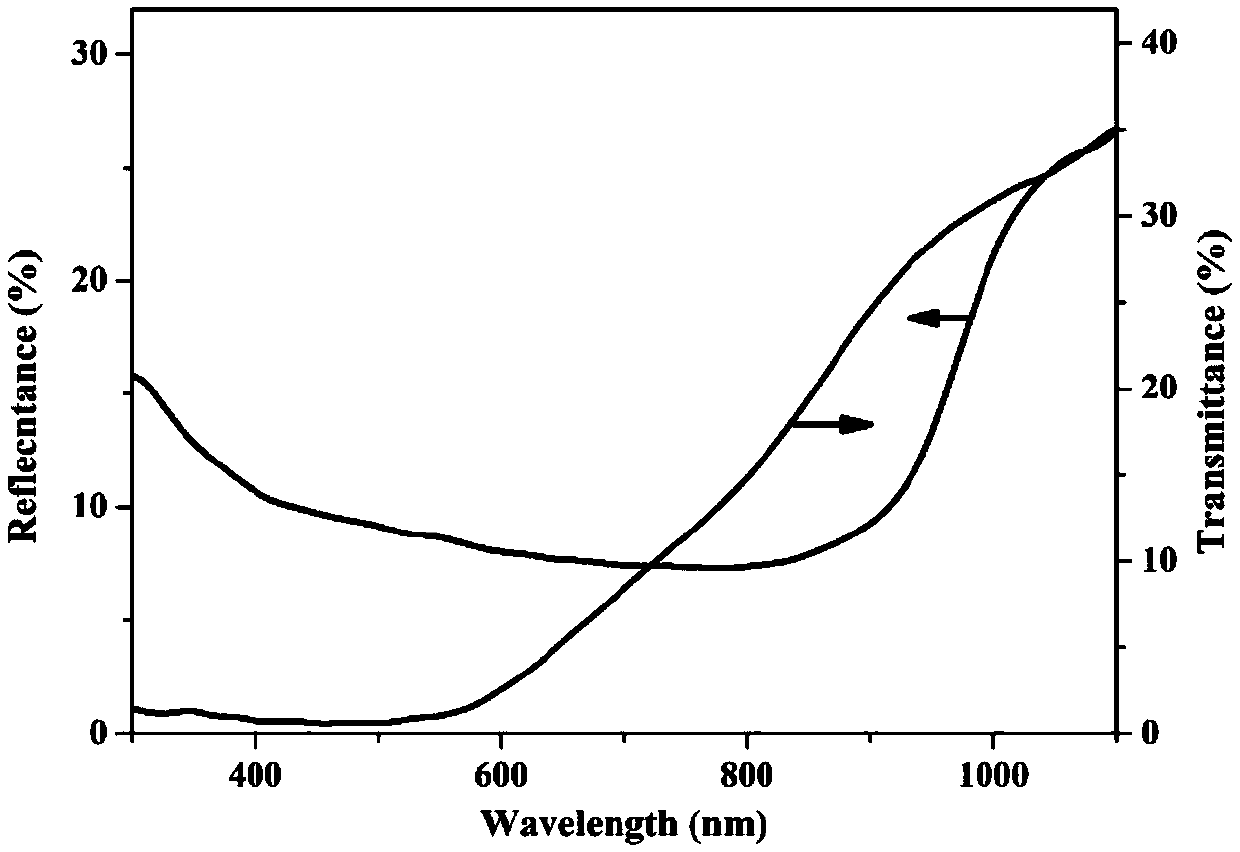

[0039] The soda-lime glass substrate was ultrasonically cleaned with soapy water, acetone, absolute ethanol, and deionized water in sequence, and a SnS film with a thickness of 10 nm was pre-deposited on the substrate by a continuous ion adsorption process. Add 0.15mol / L thioacetamide to deionized water as sulfur source solution, dissolve 0.015mol / L antimony trichloride, 0.035mol / L stannous chloride, and 0.1mol / L trisodium citrate in deionized water The ionized water is the metal source solution; after the sulfur source solution is mixed with the metal source solution, hydrochloric acid is added to adjust the pH value to 5.5, and the color of the solution is light white at this time. Stand still for 3 minutes, pour into the pre-prepared deposition beaker, then put the beaker to be deposited into a constant temperature water bath with a pre-adjusted temperature of 70°C for ...

Embodiment 2

[0041] A chemical bath preparation method for a tin-antimony-sulfur thin film, comprising the steps of:

[0042] The soda-lime glass substrate was ultrasonically cleaned with soapy water, acetone, absolute ethanol, and deionized water in sequence, and a SnS film with a thickness of 15 nm was pre-deposited on the substrate by a continuous ion adsorption process. Add 0.1mol / L thioacetamide to deionized water as sulfur source solution, dissolve 0.01mol / L antimony trichloride, 0.02mol / L stannous chloride, and 0.05mol / L trisodium citrate in deionized water The ionized water is the metal source solution; after the sulfur source solution and the metal source solution are mixed, hydrochloric acid is added to adjust the pH value to 4, and the color of the solution is light white at this time. Stand still for 3 minutes, pour into the pre-prepared deposition beaker, then put the beaker to be deposited into a constant temperature water bath with a pre-adjusted temperature of 80°C for depo...

Embodiment 3

[0044] A chemical bath preparation method for a tin-antimony-sulfur thin film, comprising the steps of:

[0045] The soda-lime glass substrate was ultrasonically cleaned with soapy water, acetone, absolute ethanol, and deionized water in sequence, and a SnS film with a thickness of 5 nm was pre-deposited on the substrate by a continuous ion adsorption process. Add 0.2mol / L thioacetamide to deionized water as sulfur source solution, dissolve 0.03mol / L antimony trichloride, 0.04mol / L stannous chloride, and 0.2mol / L trisodium citrate in deionized water The ionized water is the metal source solution; after the sulfur source solution and the metal source solution are mixed, ammonia water is added to adjust the pH value to 6, and the color of the solution is light white at this time. Let it stand for 5 minutes, pour it into the pre-prepared deposition beaker, and then put the beaker to be deposited into a constant temperature water bath with a pre-adjusted temperature of 50°C for de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com