Capsule type potato seed

A potato and capsule technology, applied in the direction of seed coating/seed dressing, can solve the problems of increased labor cost, increased operation time, large volume and weight, etc., and achieves the effect of reducing transportation and storage costs, saving labor and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

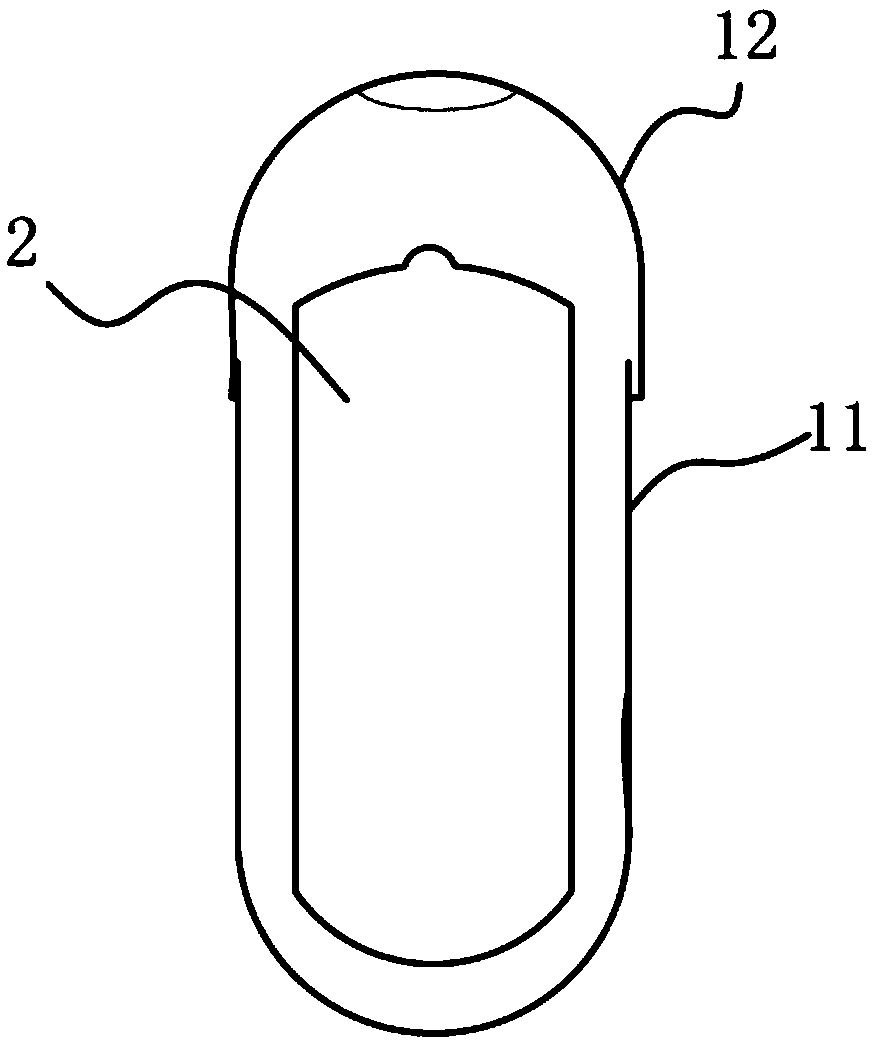

[0028] see figure 1 , a kind of capsule type potato, comprising a capsule body, the potato columnar tubers 2 with bud eyes are coated inside the capsule body.

[0029] Wherein, the capsule body includes a capsule base 11 with an open top and a capsule sealing cover 12 that seals the mouth of the capsule base, and an air hole 5 that is easy to tear is arranged at the top. Degradable biomass material, or formed by mixing nutritional components and forming aids, the capsule has airtightness, when the potato columnar tuber is contained in the capsule body to form an "artificial seed" product, the cavity of the capsule It is filled with anaerobic gas such as nitrogen to provide an anaerobic environment for the tubers.

[0030] The distance between the top of the potato columnar tuber and the top of the capsule sealing cover is preferably 1-2 cm, so as to facilitate germination before the cultivation.

[0031] Potato columnar tubers can be processed using equipment such as punches...

Embodiment 2

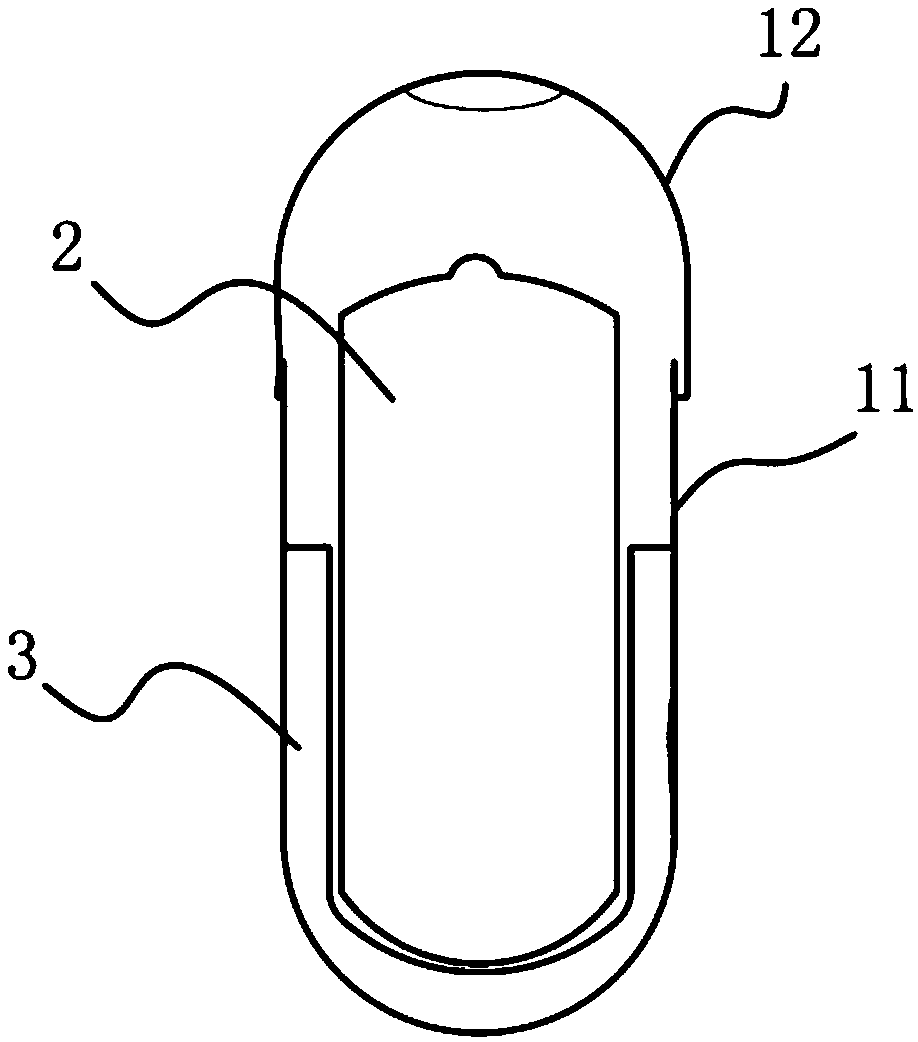

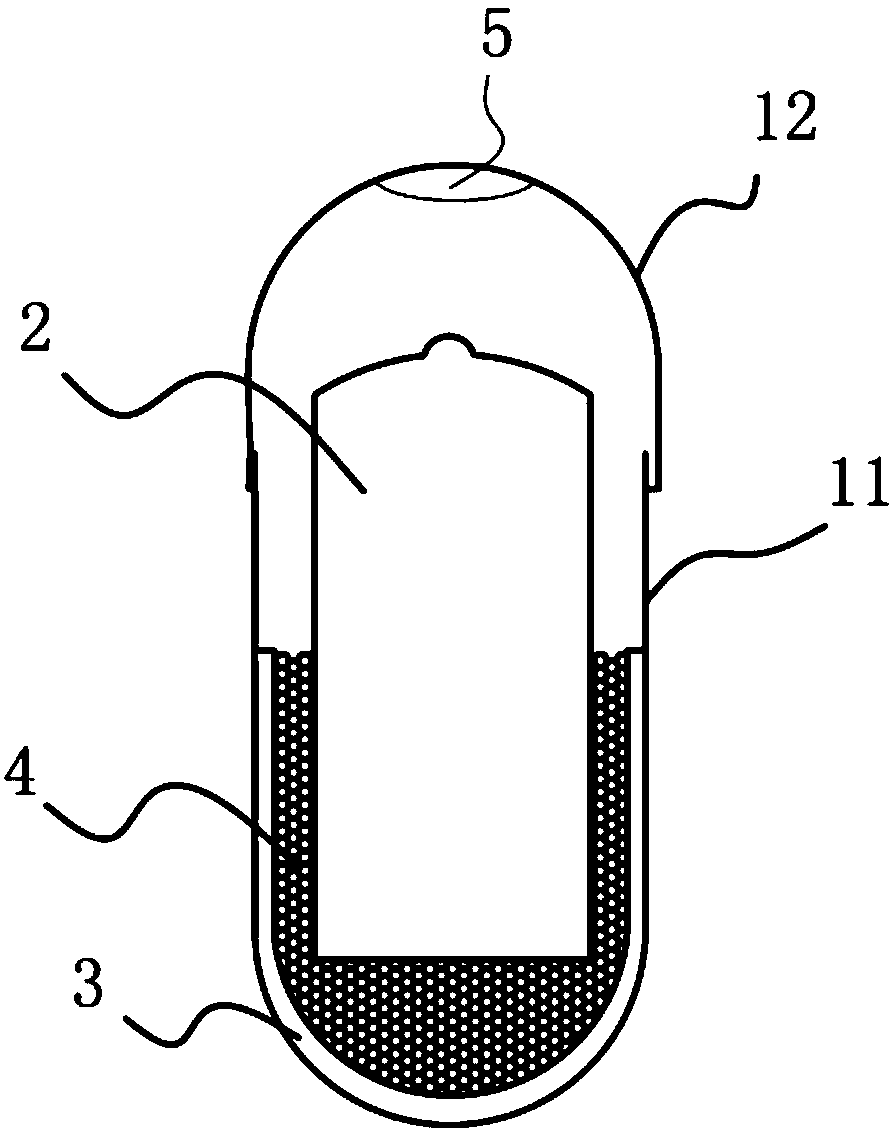

[0035] see figure 2 , in order to maximize the use of potato tubers, the remaining potato tubers without bud eyes are crushed and dried, and then supplemented with auxiliary agents to form granules or lumps, and added to the capsule body to provide the potato tubers with the necessary nutrients for germination and seedling growth. Nutrients. Therefore, the capsule body of the present invention also contains crushed potato tuber fragment particles 4 .

Embodiment 3

[0037] see image 3 , in order to maintain the ambient humidity in the capsule, the capsule body also includes an anti-collision elastic thickened paper grid liner 3, the moisture content of the elastic paper liner is 5-10%, which is applicable to different water content tubers.

[0038] The capsules prepared by the method of the present invention can be sealed in bulk, and can also be sealed and packaged in a packaging box with distributed storage chambers. The number of storage chambers in the packaging box can be determined according to production needs, and one capsule can be placed in each storage chamber. capsule.

[0039] The tuber capsules for asexually propagated potatoes of the present invention, 15-30 days before planting, destroy the pores on the top of the capsule, let the bud eyes contact with the air, and wait for the buds to be 1-2cm high, which can be achieved by traditional artificial planting and agricultural machinery developed in the later stage. The who...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com