Method for preparing active silicon@active humic acid composite fertilizer from inferior coal, and composite fertilizer obtained by using same

A technology of active humic acid and compound fertilizer, which is applied in the field of compound fertilizers containing active silicon and active humic acid, can solve the problems of low content of silicate ions of active components, complicated operation, low extraction rate, etc., and achieves easy dissolution. and dispersion, to meet the requirements of use, the effect of atomic economy is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

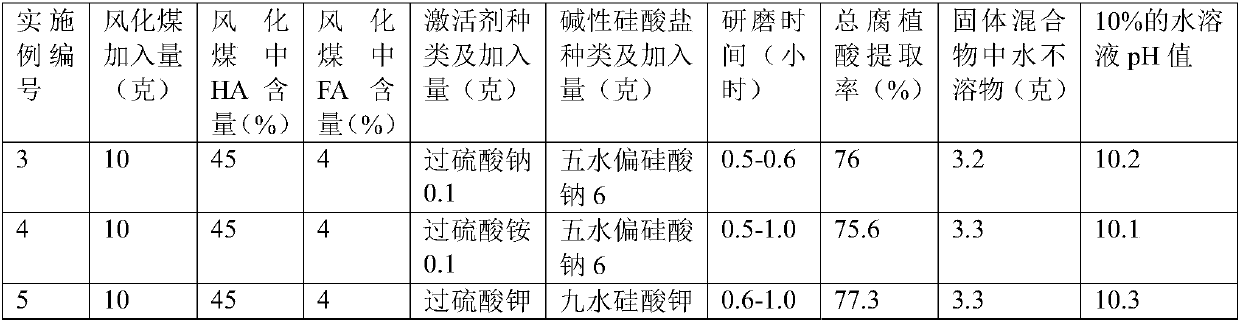

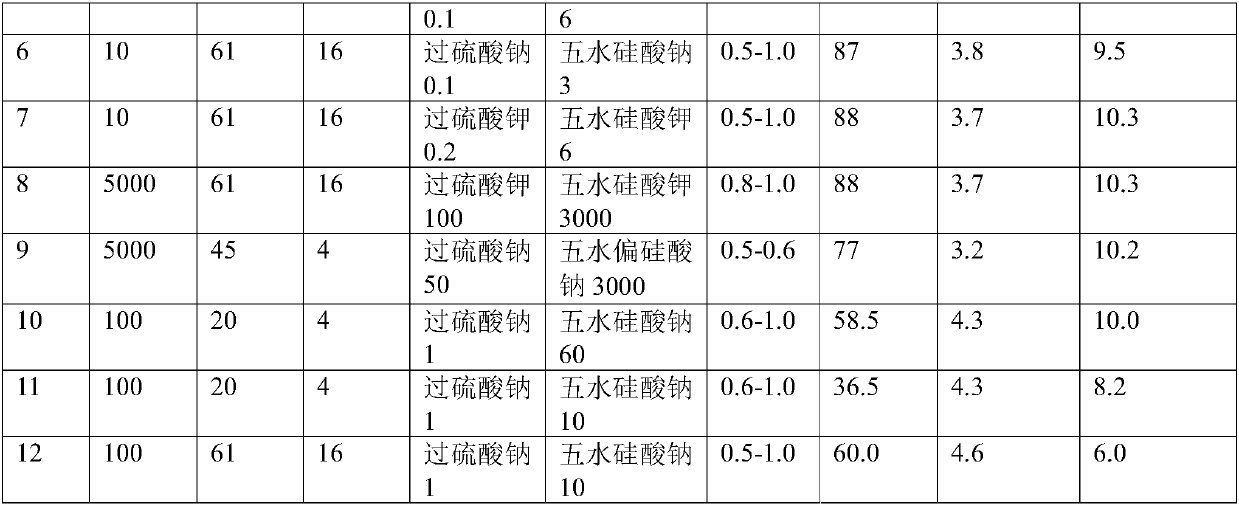

[0039] Take the weathered coal produced in a certain place as sample 1, and test its humic acid (referred to as HA) mass percentage content of 45%, and fulvic acid (referred to as FA) content of 4.0%. After passing sample 1 through a 5-mesh sieve, weigh 10.0g and place it in a grinder, add 0.1g sodium persulfate, and carry out grinding reaction at room temperature for 5-10 minutes; then add 9g sodium silicate in three portions, each time adding silicon After sodium sulfate is ground for 5-20 minutes, a solid compound fertilizer containing active humic acid-active silicon is obtained.

[0040] The compound fertilizer was tested for water solubility and humic acid content in the aqueous solution. The test method is as follows: Take 1g of the above compound fertilizer and add it to a test tube containing 7ml of tap water in 3 times. Stir evenly to observe its dissolution, dispersion and sedimentation. The content of humic acid and fulvic acid is tested according to the national stan...

Embodiment 2

[0054] The weathered coal produced in another place was taken as sample 2, and the mass percentage content of humic acid was tested to be 61%. The preparation method of the compound fertilizer was the same as that in Example 1.

[0055] The results showed that the extraction rate of total humic acid in weathered coal was 87.1% based on the extraction amount of water-soluble sodium humate. The mass content of humic acid in the obtained compound fertilizer is about 48.0%, and the content of active fulvic acid is 16.0%. Compared with the water-phase heating extraction method described in Comparative Example 1, the extraction rate of total humic acid is about 13% higher, and the extraction rate of fulvic acid is about 30% higher. If the aqueous caustic soda extraction method described in Comparative Example 2 is used, the extraction rate of humic acid is 32.7%, and the content of fulvic acid is 6.0%. It shows that the method provided by the present invention can significantly increa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com